A kind of manufacturing method of sheet material and three-dimensional structure made therefrom

A three-dimensional structure and sheet technology, which can be used in infrastructure engineering, soil protection, construction, etc., and can solve the problems of different strength and service life of nodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

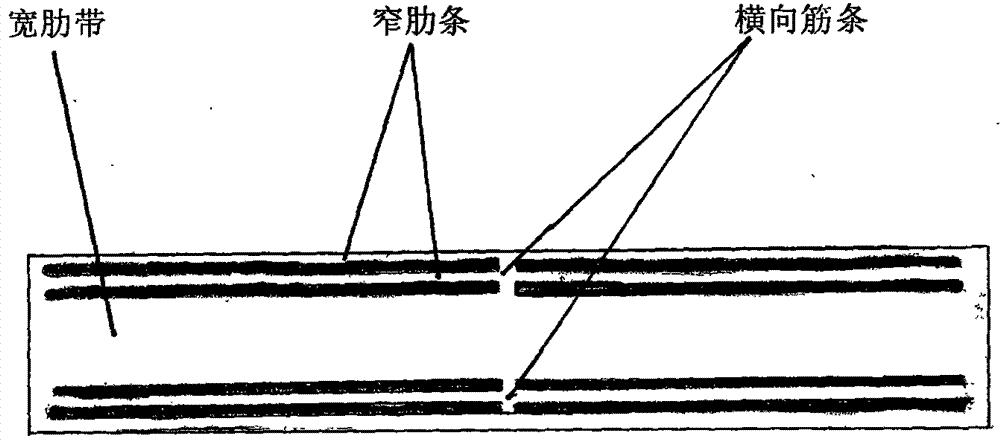

[0032] Embodiment 1: The manufacturing method of a kind of sheet material that contains repeated four narrow ribs and repeated whole transverse ribs and the three-dimensional structure made of it will be further described in conjunction with the accompanying drawings. The composition of the sheet material is as follows: figure 1 shown.

[0033] Using PP (T30S) as the main material to add certain processing aids and 5% black color masterbatch, through the extrusion of the extruder, three-roll calendering, cooling, traction and edge trimming, the width is 323MM, the thickness is 323MM. It is a 3.0MM plate.

[0034] The cross-sectional area of the selected width is an elliptical punch, the major axis of the ellipse is 70MM, and the minor axis is 7MM. From one side edge of the plate, the punches are arranged sequentially in the transverse direction of the plate: the distance between the center of the first punch (punching) and the edge of the material is 11.5MM, the distance be...

Embodiment 2

[0043] Embodiment two: select the above-mentioned sheet material containing repeated four narrow ribs and a repeated whole transverse rib, the manufacturing method of the sheet material is described in embodiment one, at first the sheet material is cut into about 8 meters long slice, the sheet material The connection of the two sheets is the same as in the first embodiment; two narrow ribs corresponding to different stations on the same side are connected. The sheet group is expanded to obtain a three-dimensional structure.

Embodiment 3

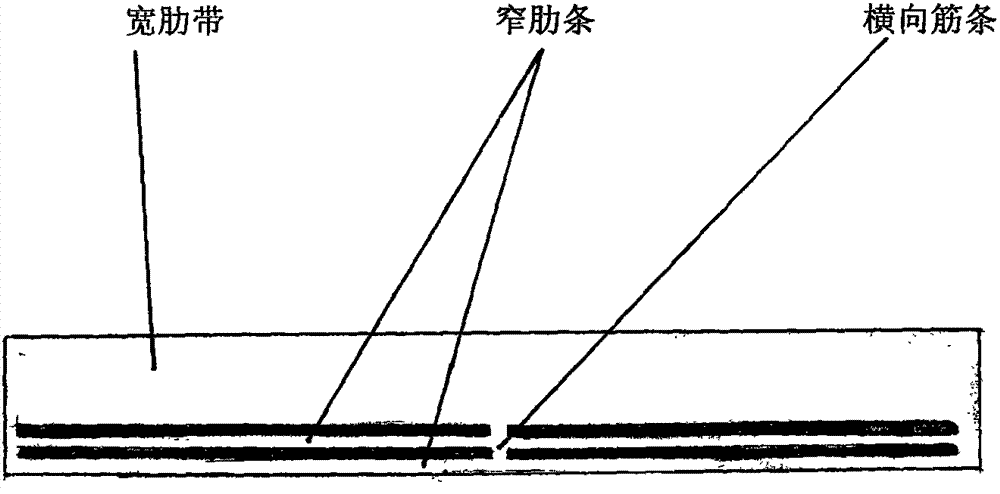

[0044] Embodiment three: a kind of manufacturing method and the three-dimensional structure made by it of the sheet material that comprises wide rib belt and repeated two narrow ribs and repeated part transverse ribs are selected for use below, and the composition of sheet material is as follows figure 2 shown.

[0045] The HDPE plate produced by the blow molding process with a thickness of 1.0MM and a width of 92MM is punched with a punch with a rectangular cross-sectional area. The length of the punch is 320MM and the width is 8MM; the length of the punch is arranged in parallel with the longitudinal direction of the plate. The center of a punch is 12MM from the edge of one side of the plate, the hole distance between the first punch and the second punch is 16MM; the step of the feeder is 338MM, and the punching die of the above hole distance arrangement and pass type Installed on a punching machine to automatically feed and punch holes, and obtain a sheet containing a wide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com