a grouting system

A technology of grouting system and grouting pipe, which is applied in the field of grouting system for bored pile grouting, which can solve problems such as uneven settlement of pile group foundation, inconvenient operation, and reduced pile side resistance, so as to avoid local collapse , easy control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

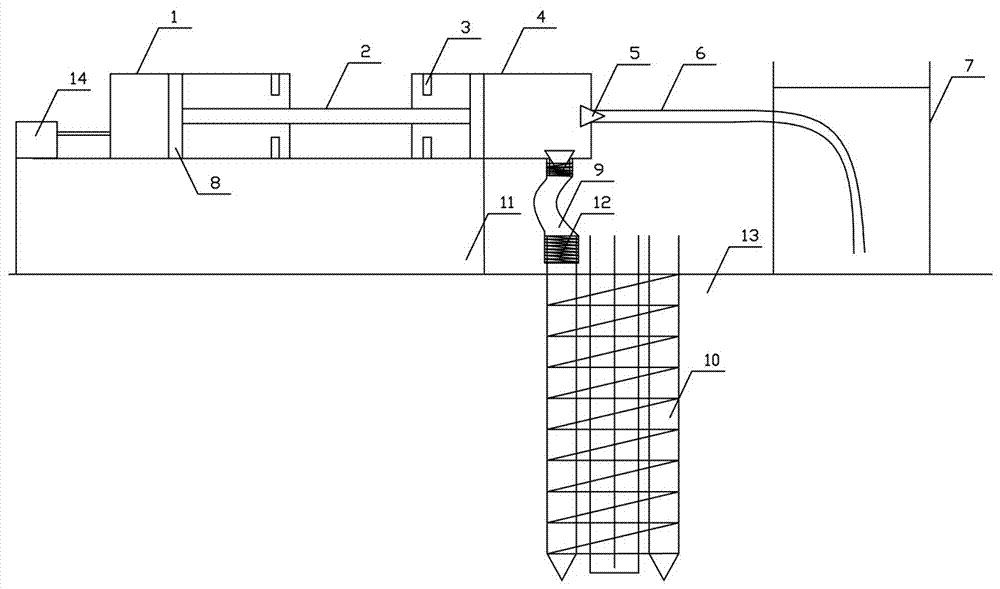

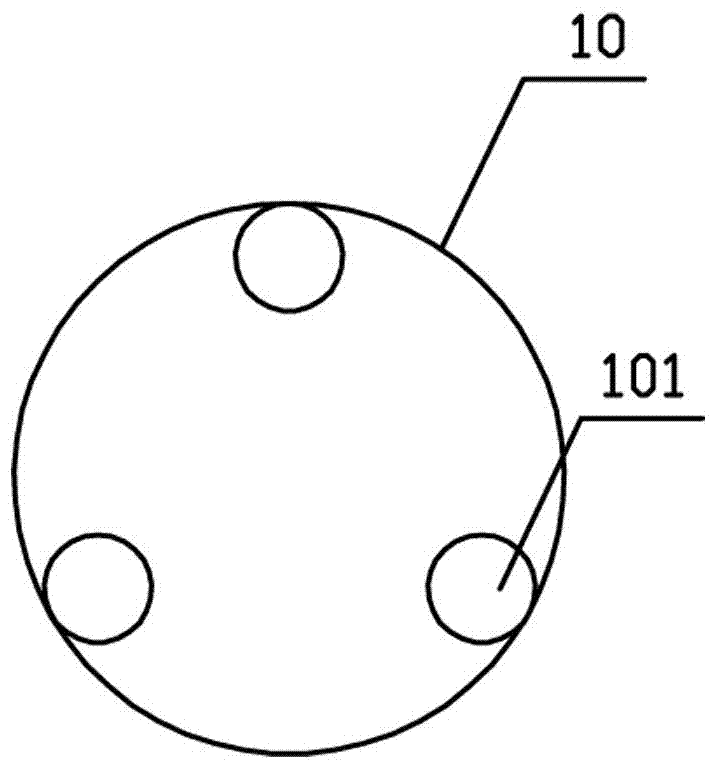

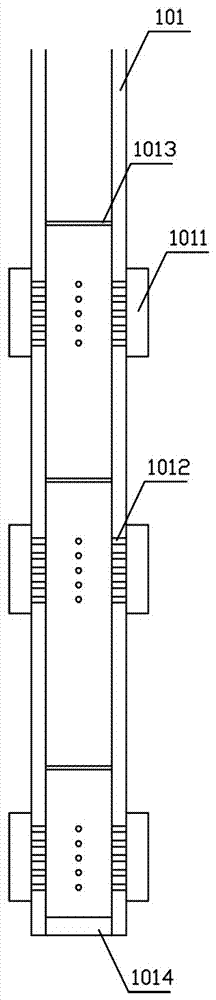

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

[0023] Such as Figure 1-Figure 6 As shown, when in use, the hydraulic pump 14 sucks hydraulic oil from the hydraulic cylinder 1, pulls the piston 8 in the hydraulic cylinder 1, the hydraulic rod 2, and the piston 8 in the material cylinder 4 to move, and is installed at the interface between the slurry suction pipe 6 and the material cylinder 4 The baffle plate 55 of the one-way valve 5 at the place is on the material cylinder 4 side, and the material of the spool 53 is cast iron. The suction force of the piston 8 overcomes the suction force of the magnet 52 and the elastic force of the rubber band 54 to do work, so that the spool 53 approaches the baffle plate 55. End movement, the slurry in the slurry tank 7 is injected into the material cylinder 4 through the gap between the hole wall of the conical through hole 56 and the valve core 53 to realize slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com