Ionic liquid electroplating solution for preparing bright aluminum coating at low temperature and using method of ionic liquid electroplating solution

An ionic liquid and aluminum coating technology, applied in the field of preparing bright aluminum coating, can solve the problems of pollution, high operating temperature, equipment corrosive environment, etc., achieve clean and easy process, great application prospect, and overcome the effect of volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of plating solution

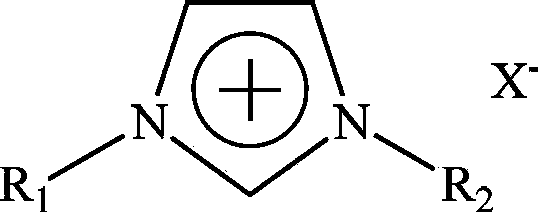

[0032] The electroplating solution is arranged in the glove box and is protected by inert gas. The three components of the electroplating solution are: (A) is anhydrous AlCl 3 , (B) is dried 1-ethyl-3-methylimidazole chloride, and additive (C) is pyridine-3-carboxylic acid (as shown in structural formula 3). Weigh AlCl with an apparent molar ratio of 2:1 3 And 1-ethyl-3-methylimidazole chloride, add a small amount of AlCl 3 Carefully add to 1-ethyl-3-methylimidazole chloride, wait until the AlCl is added 3 Dissolve completely, then take a small amount and continue adding until the addition is complete. After the two form a homogeneous solution, stir at 50°C for 2 to 3 hours, and the formed homogeneous transparent liquid is the composite ionic liquid (D). Add 1g / L of additive (C), stir to completely dissolve, and obtain ionic liquid / additive electroplating solution.

[0033]

[0034] Structural formula 3

[0035] 2) Plating process

[0036]...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is that the two substances (A) and (B) with an apparent molar ratio of 1.5:1 are mixed to form a composite ionic liquid (D), and the additive (C) added is 3-pyridine Formamide (as shown in structural formula 4); the current density during plating is 0.8A / dm 2 , Others are the same as in Example 1, and the mirror-bright aluminum coating can also be obtained.

[0039]

[0040] Structural formula 4

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 or 2 is that the additive (C) in the preparation of the plating solution is replaced with methyl 3-picolinate (as shown in structural formula 5). Others are the same as Embodiment 1 or 2, and the mirror-finished aluminum coating can also be obtained.

[0043]

[0044] Structural formula 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com