Dextranase and application of same in preparation of low molecular dextran

A technology of dextranase and dextran, which is applied in the direction of enzymes, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of non-concentrated product molecular weight distribution, unfavorable environmental protection, low-carbon and other problems, and achieve The effect of lower production process cost, lower production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for isolating strain F1008 producing dextranase high enzyme activity, which comprises the following steps:

[0028] Add 1g of soil samples (soil samples were taken from Hefei, Anhui, Bengbu, Anhui, and Chengdu, Sichuan) to 99ml sterile water to prepare soil dilution, add penicillin solution (50μl to 100ml) into the PDA medium, pour it into a petri dish, and let it stand Let cool into a flat plate. Use the dilution coating method to apply the diluted soil solution on the plate respectively, and then place it upside down in a constant temperature incubator at 30°C for cultivation. After the bacteria grow out, use the inoculation needle to pick the strain into another sterile screening culture base (Formulation: Dextran T20001g, NaNO 3 0.3g, K 2HPO 4 ·3H 2 O0.4g, MgSO 4 ·7H 2 O0.02g, KCl0.02g, FeSO 4 ·7H 2 (0.001g, agar 1.6g, water 100ml, pH5.0~5.5) were streaked and separated, and then the single colonies that could grow on the screening medium were picke...

Embodiment 2

[0031] The technical scheme of using Penicillium aculeatus F1008 to produce dextranase:

[0032] 1) Strain activation: Use sterilized solid PDA medium to inoculate the F1008 strain on the slant medium of the test tube, cultivate it at 28-30°C for 48-60 hours, and then use it to prepare the strain seed solution;

[0033] 2) Strain seed fermentation culture: the composition of the seed medium is 1.5g of Dextran100kDa per 100ml of water, 0.4g of peptone, K 2 HPO 4 ·3H 2 O0.1g, NaNO 3 0.2g, MgSO 4 ·7H 2 O0.05g, KCl0.05g, FeSO 4 ·7H 2 O0.001g, pH5.0-5.5, inoculate the strain in step 1) into the seed medium, place it on a constant temperature shaker at 30-32°C, and cultivate it for 48-72 hours at a speed of 220r / min as seeds liquid, and then use the seed liquid for fermentation to prepare dextranase;

[0034] 3) Preparation of dextranase by fermentation: the components of the fermentation medium are 1.5g of Dextran100kDa per 100ml of water, 0.4g of peptone, K 2 HPO 4 ·3H ...

Embodiment 3

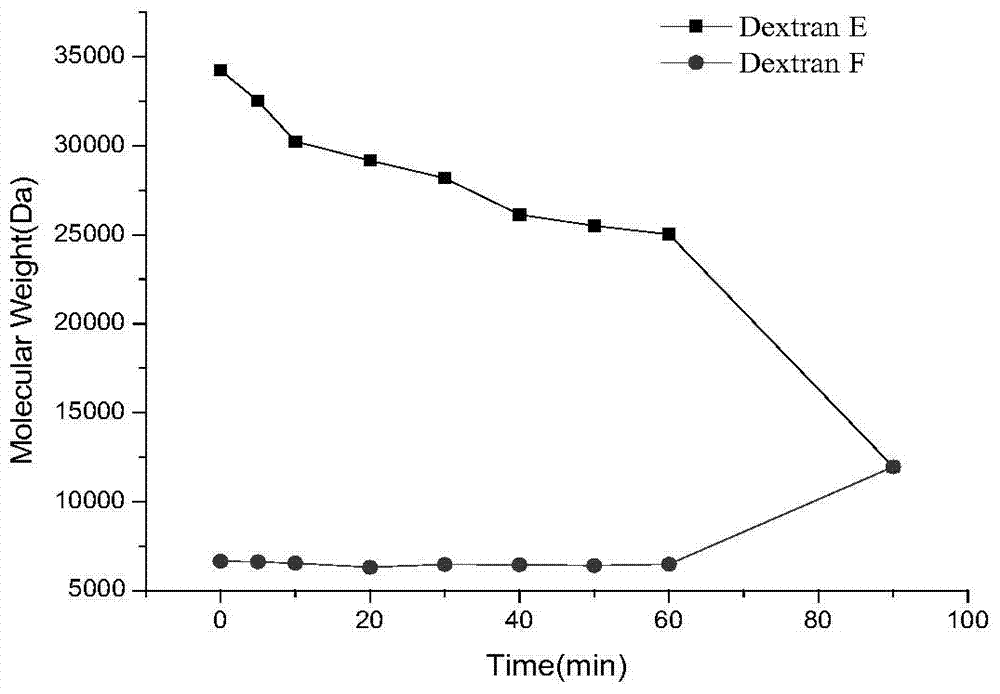

[0038] Application of Penicillium aculeatus F1008 in the preparation of low molecular weight dextran:

[0039] Add 240g of sucrose and 2000mL of buffer solution to an electric mechanical stirring device and a temperature-controlled beaker in a water bath. After stirring to dissolve fully, control the temperature of the water bath at 30°C, and add 4000U of dextran sucrase and 5000U of dextranase at the same time, and stir for 22- After 24 hours, raise the temperature of the water bath to 80°C and keep it warm for 1 hour to inactivate dextran sucrase. After filtering the denatured enzyme protein with gauze, place it in a boiling water bath for 20 minutes to inactivate the residual dextranase. Then vacuum filter to obtain a clear and transparent filtrate. , which is low molecular weight dextran solution.

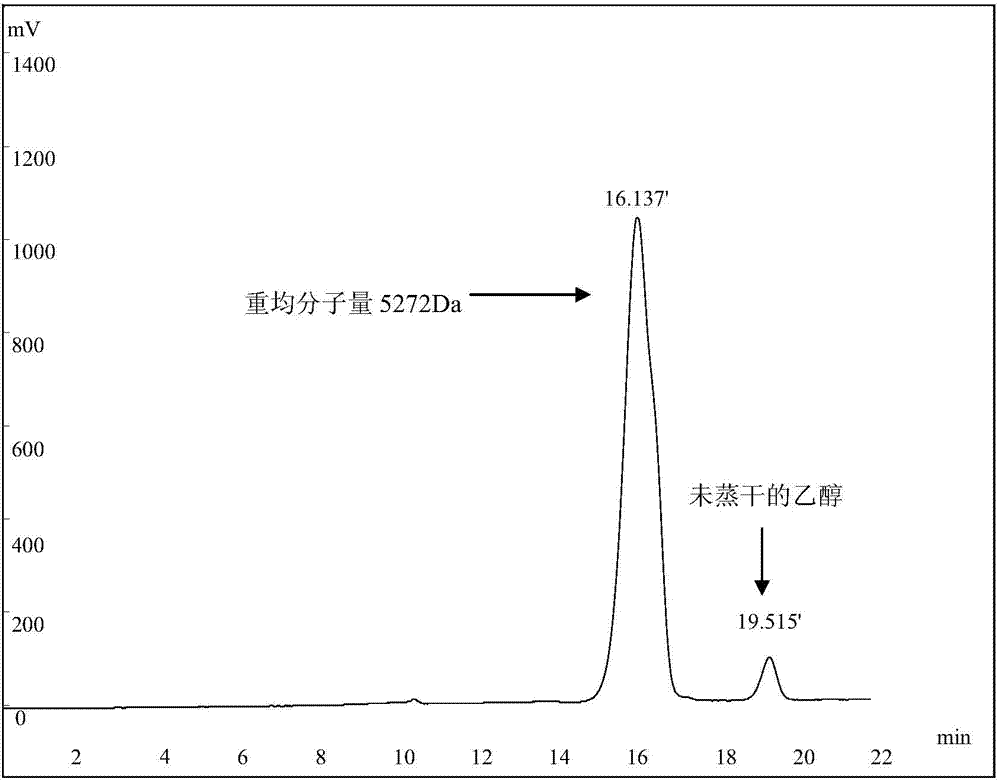

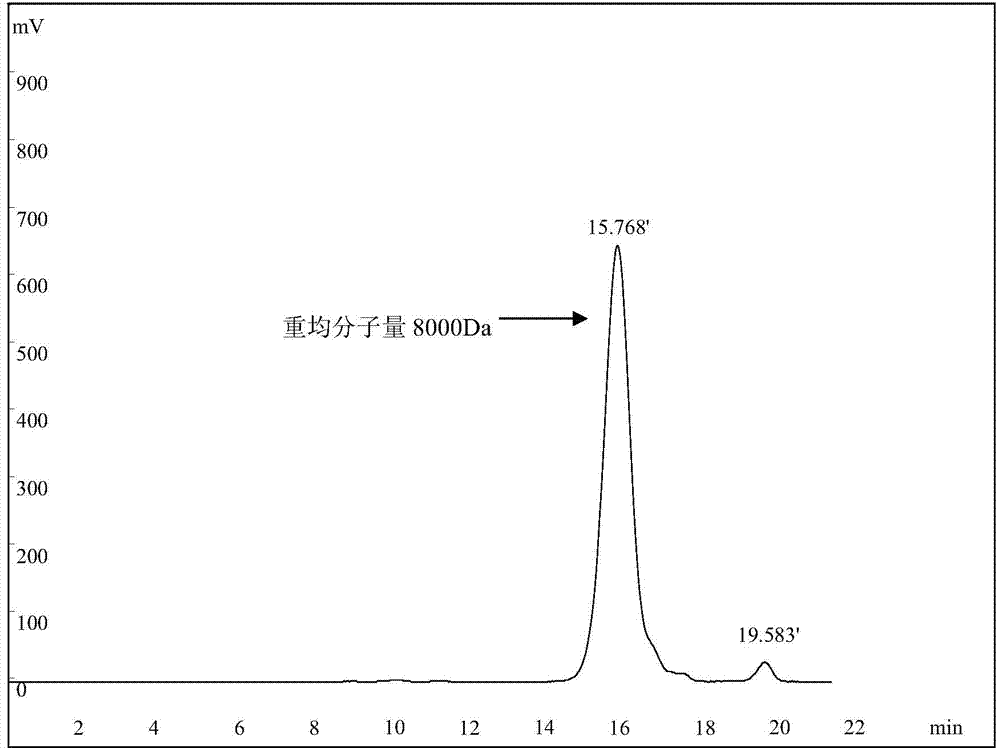

[0040] The solution was concentrated by rotary evaporation at 70°C to remove part of the water, concentrated to half of the original volume and subjected to fractional alcohol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com