Heavy metal immobilizing agent and method for immobilization and stabilization of soil heavy metals by using heavy metal immobilizing agent

A curing agent and heavy metal technology, applied in chemical instruments and methods, restoration of polluted soil, soil conditioning materials, etc., can solve problems such as affecting social stability, harming people's health, endangering environmental safety, etc., and achieving good curing effect and raw materials. Inexpensive, good curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the mass percentages of the components of curing agent A are: fly ash 70%, cement 10%, carbide slag 20%; solid-liquid ratio of curing agent B is 0.3W / W. The specific method steps are as follows:

[0038] a. Select the heavy metal-contaminated soil and the solidifying agent A at a mass ratio of 20:100 to select the heavy metal-contaminated soil, mix and stir the heavy metal-contaminated soil and the solidifying agent A to obtain a uniform mixture;

[0039]b. Bake the homogeneous mixture in step a in an oven at 105°C for 2h to 4h;

[0040] c. Add curing agent B according to the solid-to-liquid ratio of 0.3W / W, stir evenly, and put it into a mold for molding;

[0041] d. Remove the mold after 24 hours, and maintain them for 28 days under natural conditions.

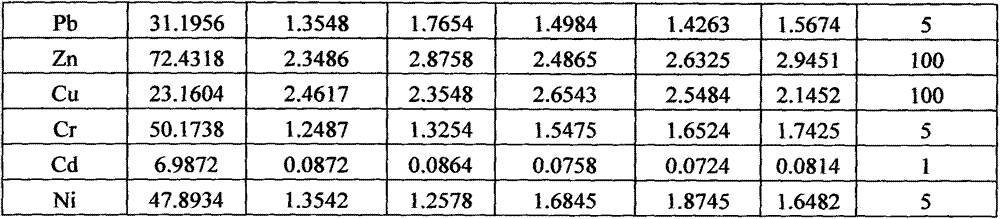

[0042] f. Use "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007) to carry out toxic leaching of heavy metal contaminated soil after curing agent treatmen...

Embodiment 2

[0048] The mass percentages of the components of curing agent A in this embodiment are: fly ash 65%, cement 10%, carbide slag 25%; solid-liquid ratio of curing agent B is 0.3W / W. The specific method steps are as follows:

[0049] a. Select the heavy metal-contaminated soil and the solidifying agent A at a mass ratio of 25:100 to select the heavy metal-contaminated soil, mix and stir the heavy metal-contaminated soil and the solidifying agent A to obtain a uniform mixture;

[0050] b. Bake the homogeneous mixture in step a in an oven at 105°C for 2h to 4h;

[0051] c. Add curing agent B according to the solid-to-liquid ratio of 0.3W / W, stir evenly, and put it into a mold for molding;

[0052] d. Remove the mold after 24 hours, and maintain them for 28 days under natural conditions.

[0053] f. Use "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007) to carry out toxic leaching of heavy metal contaminated soil after curing agent treatmen...

Embodiment 3

[0056] In this embodiment, the mass percentages of the components of curing agent A are: fly ash 60%, cement 15%, carbide slag 25%; solid-liquid ratio of curing agent B is 0.4W / W. The specific method steps are as follows:

[0057] a. Select the heavy metal-contaminated soil and the solidifying agent A at a mass ratio of 30:100 to select the heavy metal-contaminated soil, mix and stir the heavy metal-contaminated soil and the solidifying agent A to obtain a uniform mixture;

[0058] b. Bake the homogeneous mixture in step a in an oven at 105°C for 2h to 4h;

[0059] c. Add curing agent B according to the solid-to-liquid ratio of 0.4W / W, stir evenly, and put it into a mold for molding;

[0060] d. Remove the mold after 24 hours, and maintain them for 28 days under natural conditions.

[0061] f. Use "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007) to carry out toxic leaching of heavy metal contaminated soil after curing agent treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com