Method for calculating material removal rate for liquid magnetic grinding tool small hole finishing processing

A liquid magnetic and finishing technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as the inability to achieve quantitative control and affect the development, promotion and application of special machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

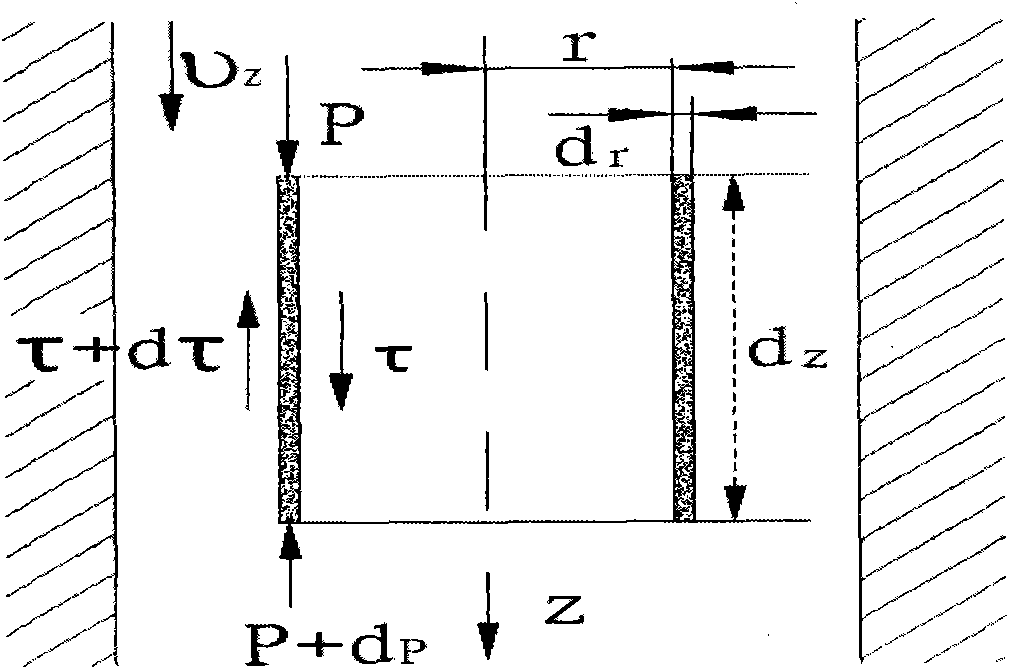

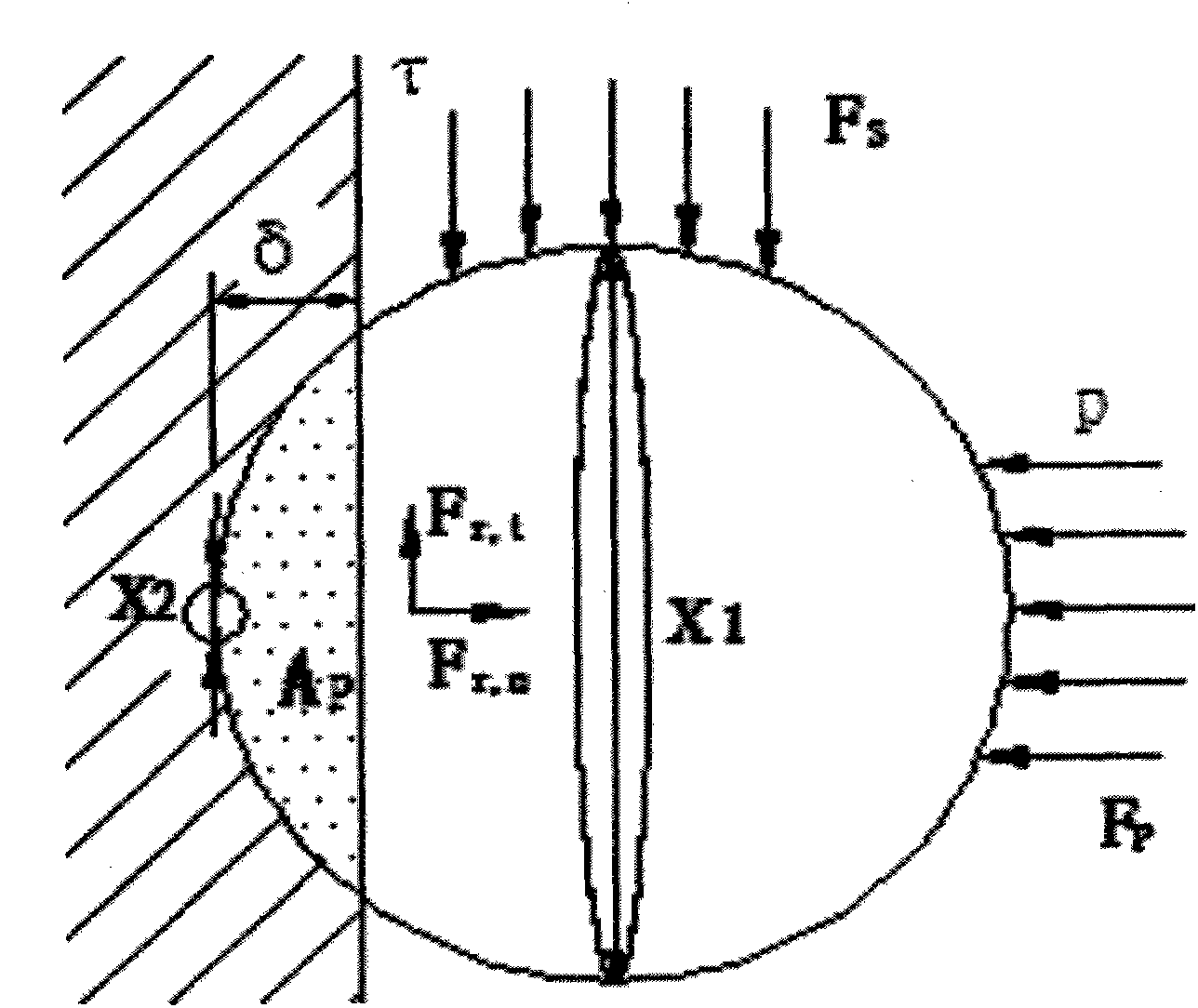

[0065] Guided by the theory of magneto-induced phase transition, the invention expounds the material removal mechanism of liquid magnetic grinding tool hole finishing from a microcosmic perspective. Using the "double edge circle radius" model to study the cutting model of a single abrasive particle, the mathematical expression of the material removal rate in the finishing process of small holes is obtained.

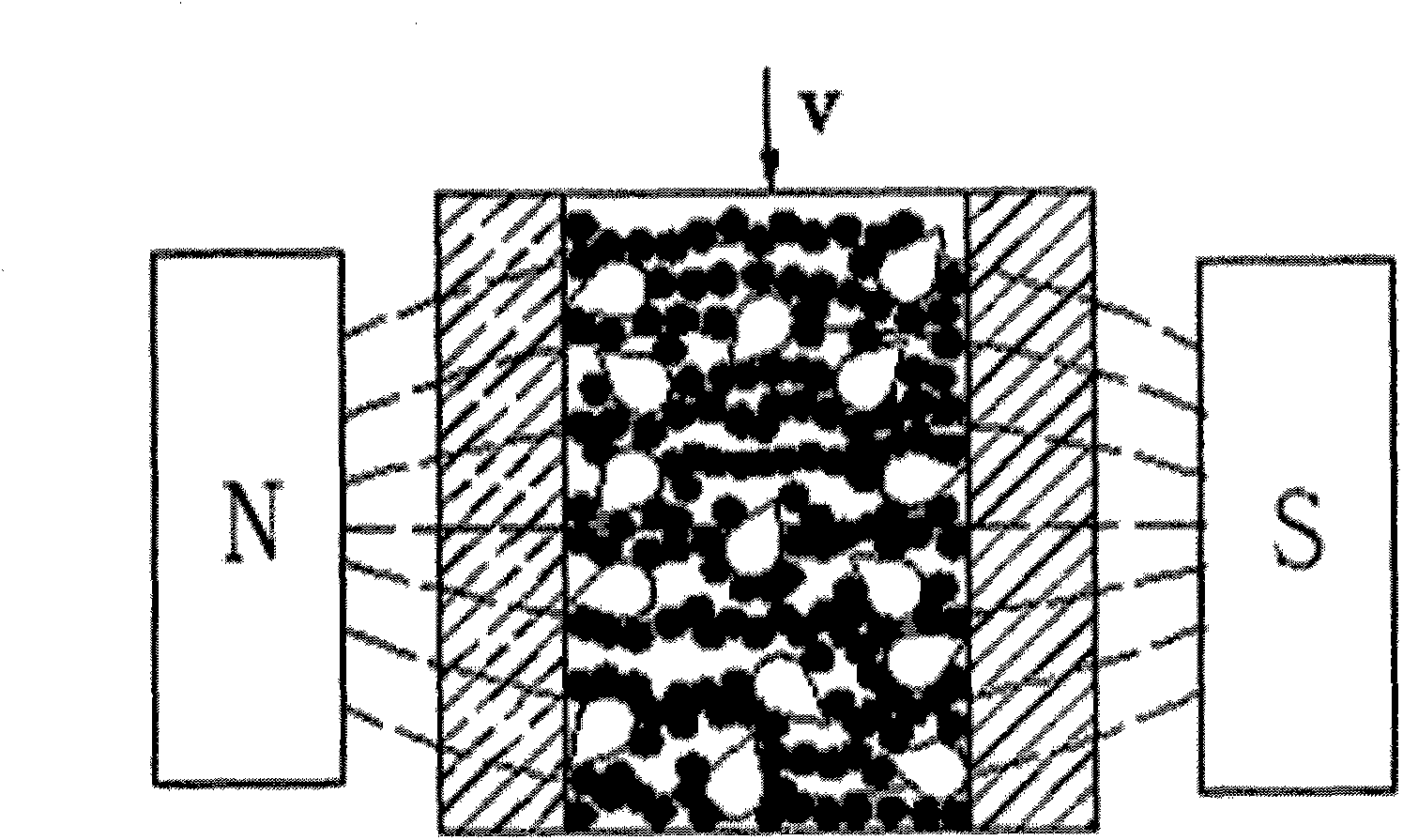

[0066] see figure 1 As shown, it is a mechanism diagram of liquid magnetic abrasive tool for small hole inner wall surface finishing of the present invention. Liquid magnetic abrasive tool is a new type of intelligent precision finishing abrasive based on the theory of magneto-induced phase transition. It consists of carrier liquid, magnetic Granules, abrasive particles and stabilizers. The magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com