Device and method for recycling ammonia nitrogen from coking wastewater

A technology for coking wastewater and ammonia recovery, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increased treatment cost, low recovery efficiency, poor separation selectivity, etc. achieve good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation of embodiment 1 diffusion dialysis membrane

[0039] Cellulose diacetate (L.R, acetic acid binding capacity 54.5-56%, moisture content ≤ 5.0%), polyethylene glycol 400 (A.R, molecular weight 370-460) and acetone (C.P) are used as membrane materials.

[0040] Preparation:

[0041] (1) Weigh 25g of cellulose diacetate, add 500ml of acetone, and stir on a magnetic stirrer for 24 hours to fully dissolve the cellulose diacetate, and prepare a cellulose diacetate acetone solution with a concentration of 5% (W / V);

[0042] (2) Use a pipette to absorb 20ml of polyethylene glycol 400 and add it to the above-mentioned cellulose diacetate acetone solution, and then leave it to stand for 1 hour after airtight stirring to obtain a film-making solution; the concentration of polyethylene glycol 400 is 4% (V / V);

[0043] (3) Use a commercially available nylon cloth with a pore size of 100 mesh and a thickness of 0.15mm as the carrier, cut it into strips with a width ...

Embodiment 2 4

[0044] Embodiment 2 Preparation of sodium tetraphenylborate-polyethylene glycol 10000 composite precipitant and composite precipitant replenishing liquid

[0045] Composite precipitant preparation:

[0046] (1) Sodium tetraphenylborate (AR) and polyethylene glycol 10000 (AR, molecular weight 8800-11200) are used as raw materials for compound precipitant preparation.

[0047] (2) Weigh 3g of sodium tetraphenylborate and 6g of polyethylene glycol 10000 and dissolve them in 200ml of deionized water respectively, mix the two solutions and set the volume to 500ml to prepare a composite precipitant. The concentration of sodium tetraphenylborate in the composite precipitant is 0.6% (W / V), and the concentration of polyethylene glycol 10000 is 1.2% (W / V).

[0048] Composite precipitant supplement solution preparation:

[0049] Weigh 12.5g of sodium tetraphenylborate and 25g of polyethylene glycol 10000 and dissolve them in 100ml of deionized water respectively, mix the two solutions ...

Embodiment 3

[0050] Embodiment 3 reclaims ammonia nitrogen from coking wastewater

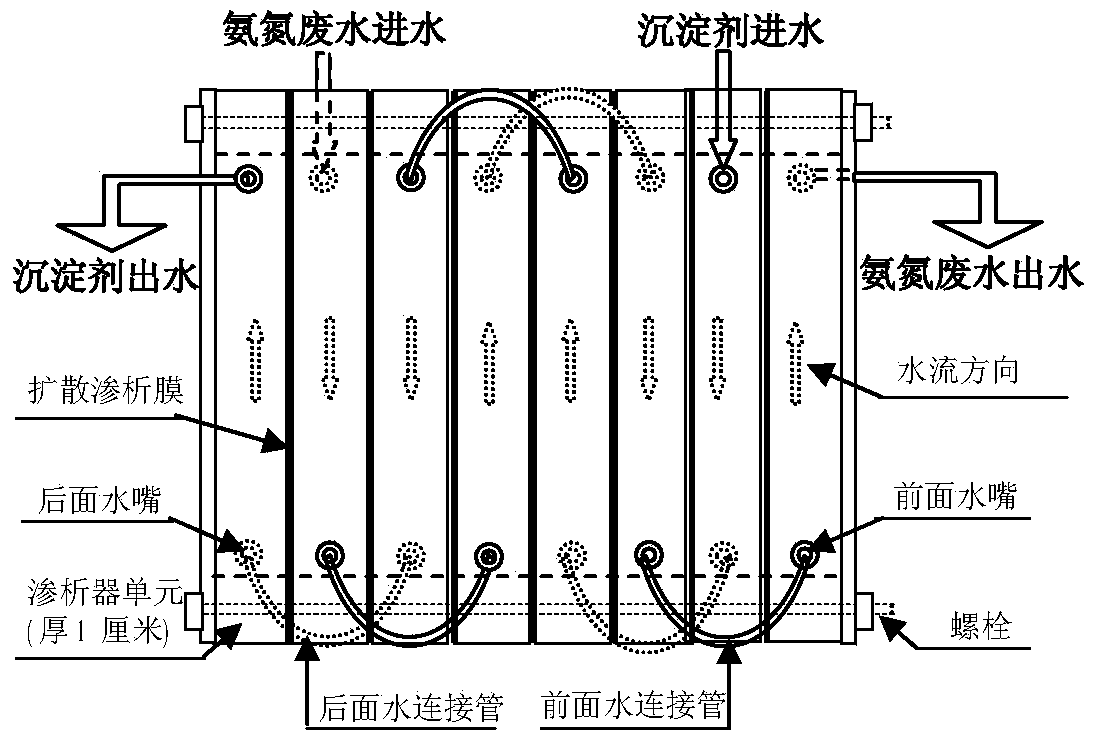

[0051] Assemble the diffusion dialysis device: cut the diffusion dialysis membrane made in Example 1 into 7 membrane blocks with a size of 70mm×100mm, and clamp them in the diffusion dialysis membrane made of 8 PE (polyethylene) plates with a thickness of 1cm respectively. Between the unit, use bolts to compress. The storage capacity of coking wastewater and composite precipitant aqueous solution in the device is 140ml respectively, and the total effective permeable membrane area is 245cm 2 .

[0052] The coking wastewater (taken from a coking plant in Taiyuan, NH 4 + Concentration of 520mg / L, COD concentration of 5103mg / L) 200ml and 500ml of the composite precipitant prepared in Example 2 respectively passed through the diffusion dialysis device with the flow rate of 50ml / min. and 100ml / min. (Such as figure 1 Shown) the respective plate and frame flow channels, the coking wastewater and the composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com