High-strength collagen base artificial bone repair material

A technology of collagen-based human and repair materials, which is applied in the field of high-strength collagen-based artificial bone repair materials and artificial bone materials. performance, good biological activity, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, preparation of high-strength collagen / nano calcium phosphate composite artificial bone

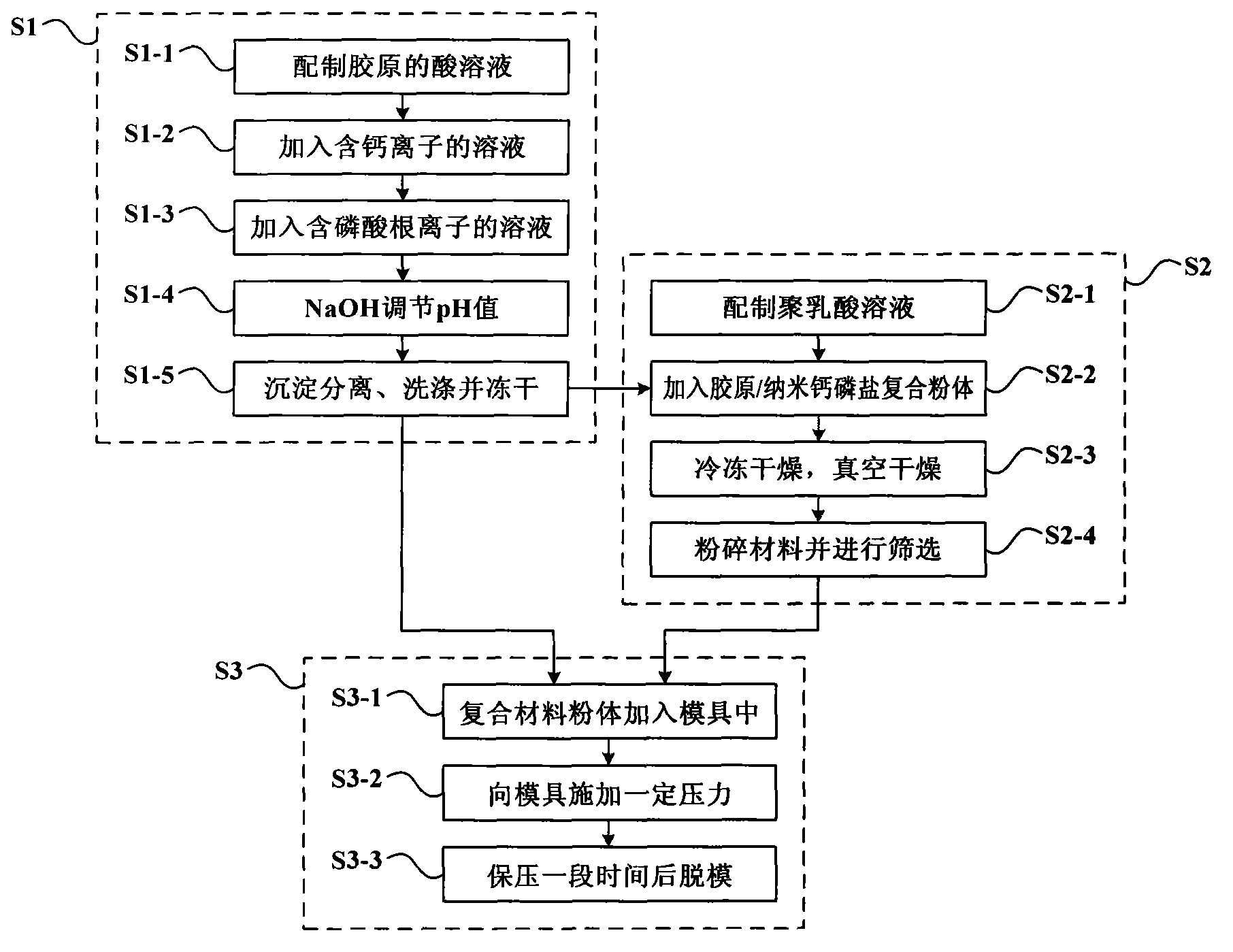

[0060] figure 1 Shown is the process flow chart of the preparation method of the high-strength collagen-based artificial bone repair material of the present invention. according to figure 1 In the steps shown, the preparation method of high-strength collagen / nano-calcium-phosphate composite artificial bone is:

[0061] Step S1-1, dissolving 1 g of collagen in 2 L of 0.5 mol / L acetic acid solution to prepare a collagen acid solution;

[0062] Step S1-2, keep stirring the solution obtained in Step S1-1, slowly add 100 mL of CaCl with a concentration of 1 mol / L dropwise 2 solution;

[0063] Step S1-3, continue to stir the solution obtained in step S1-2, and slowly add 100 mL of Na with a concentration of 0.6 mol / L dropwise 2 HPO 4 solution;

[0064] Step S1-4, continuously stirring the solution obtained in step S1-3, slowly adding 1 mol / L NaOH solution dropwise unt...

Embodiment 2

[0071] Embodiment 2, preparation of high-strength collagen / nano calcium phosphate / polylactic acid composite artificial bone

[0072] First, the collagen / nano-calcium phosphate composite material was prepared as described in Steps S1-1 to S1-5 of Example 1.

[0073] Then, the preparation of the collagen / nano-calcium phosphate / polylactic acid composite material includes:

[0074] Step S2-1, taking 1 g of polylactic acid with a molecular weight of 100,000 and dissolving it in 10 mL of 1,4-dioxane at 50°C to prepare a polylactic acid solution;

[0075] Step S2-2, adding 1 g of the dry powder prepared in step S1-5 to the polylactic acid solution obtained in step S2-1, and mixing uniformly to prepare a collagen / nano calcium phosphate / polylactic acid mixed suspension system;

[0076] Step S2-3, freeze the mixed suspension system obtained in step S2-2 at -10°C for 2 hours, then freeze-dry for 48 hours, and then transfer to a vacuum drying oven with a vacuum degree of -0.1MPa and dry ...

Embodiment 3

[0080] Embodiment 3, preparation of high-strength collagen / nano calcium phosphate / polylactic acid-glycolic acid copolymer composite artificial bone

[0081] Materials were prepared according to the steps described in Example 2. Wherein, the polylactic acid described in step S2-1 is replaced with a polylactic acid-glycolic acid copolymer (lactic acid / glycolic acid=50 / 50) with a molecular weight of 120,000, the applied pressure in step S3-2 is 155kN, and the remaining operating and process parameters are not changed. Change, so as to obtain collagen / nano calcium phosphate / polylactic acid-glycolic acid copolymer composite artificial bone.

[0082] After testing, the composite artificial bone density is 1.85g / cm 3 , the compressive strength is 145MPa, and the bending strength is 84MPa, which is suitable for the repair of human bone defects in load-bearing parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com