Electrode including porous coating layer, method for manufacturing same, and electrochemical device including same

一种多孔涂层、制造方法的技术,应用在具有多孔涂层的电极、其制造和包括其的电化学器件领域,能够解决密度降低、表面粗糙等问题,达到良好品质、有助于安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

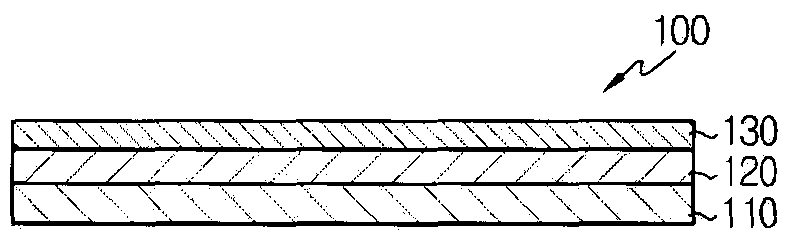

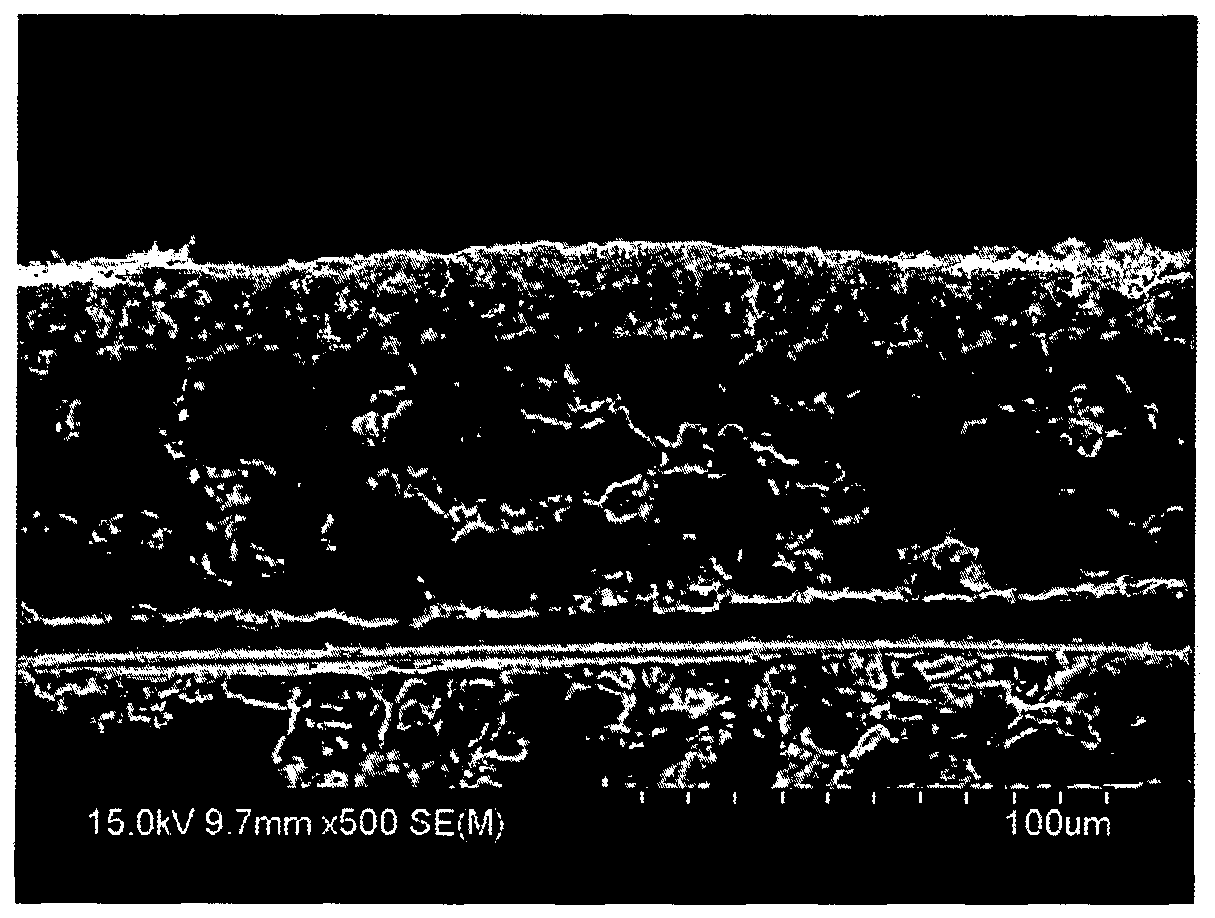

[0075] Embodiment 1: After the anode active material particle slurry and the inorganic particle slurry are applied, electrode

[0076] A first binder polymer was prepared by mixing styrene butadiene rubber (SBR) and carboxymethyl cellulose (CMC) in a weight ratio of 2:1, and the first binder polymer was added as the first solvent in water and dissolved to obtain a binder solution. Graphite as anode active material particles and Super-P (Super-P) as a conductive material were mixed into a binder solution to obtain an anode active material particle aqueous slurry.

[0077] Meanwhile, a second binder polymer was prepared by mixing styrene butadiene rubber (SBR) and carboxymethylcellulose (CMC) at a weight ratio of 2:1, and the second binder polymer was added to water as a second solvent and solvent to obtain an aqueous solution. Will be made of alumina (Al 2 o 3 ) and barium titanate (BaTiO 3 ) were dispersed at a weight ratio of 9:1 to prepare inorganic particles to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com