Electrolyte material with perovskite structure

A technology of electrolyte material and perovskite structure, used in solid electrolyte fuel cells, circuits, fuel cells, etc., can solve problems such as reducing cell efficiency and increasing electrolyte electronic conductance, reducing activation energy, facilitating conduction, and high conductance. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

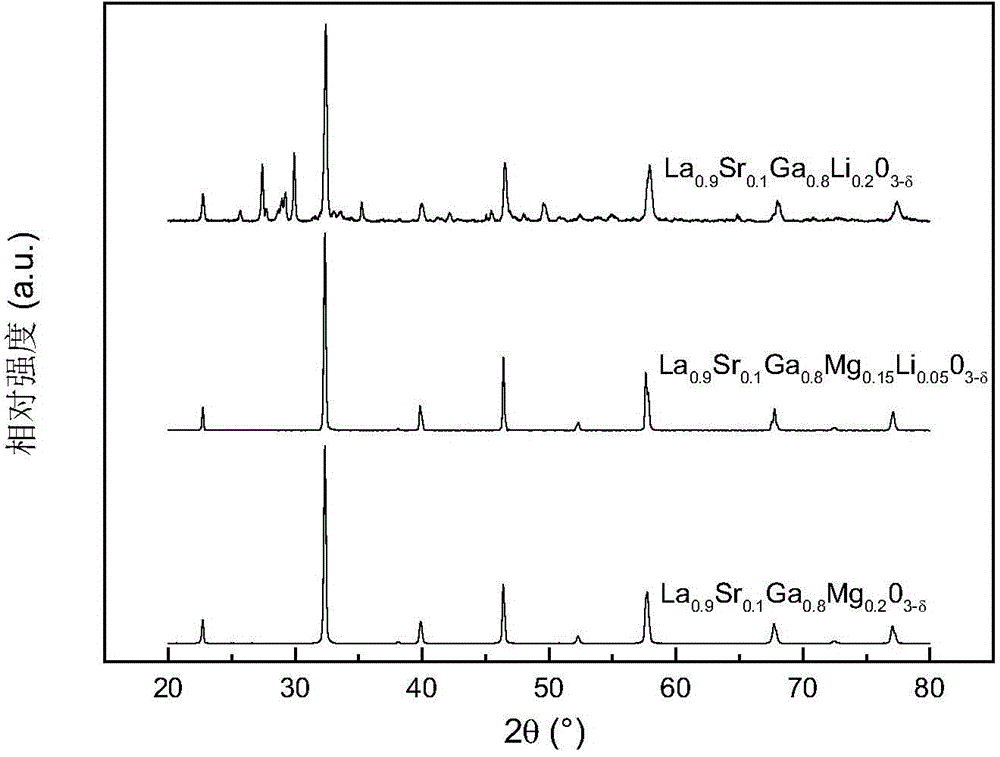

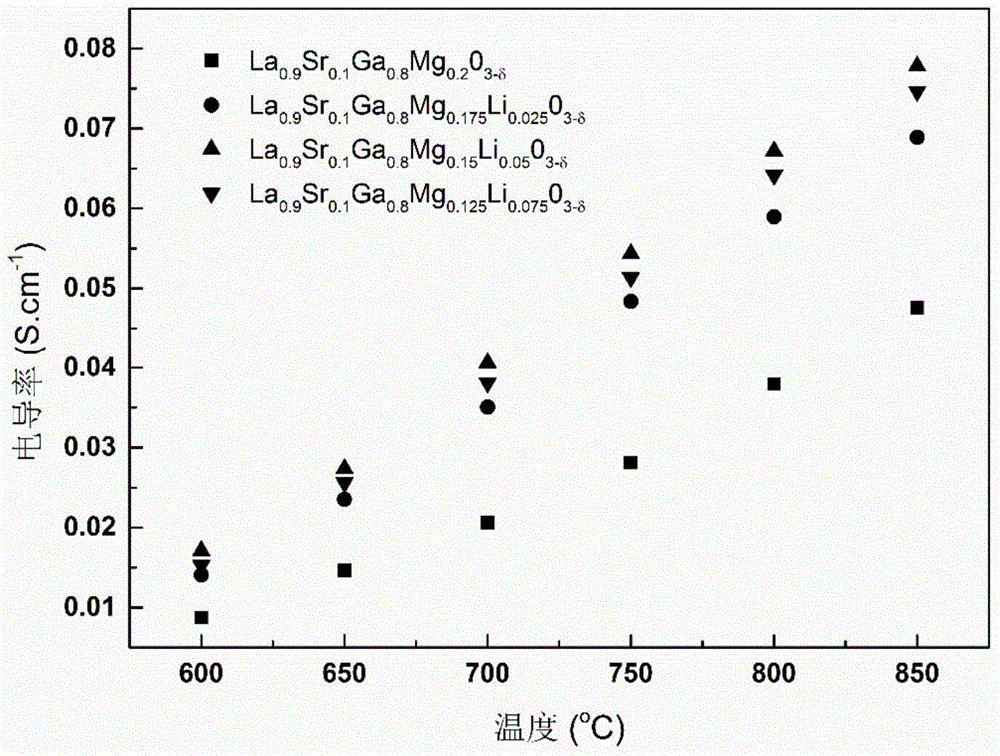

[0013] The electrolyte material of perovskite structure that the present invention proposes, its chemical formula is La 1-a Sr a Ga 1-b-c Mg b Li c o 3-δ , where a=0.01~0.2, b=0.01~0.25, c=0.01~0.2, δ=(a+b) / 2+c.

[0014] The above-mentioned electrolyte material is characterized in that the method comprises the following steps:

[0015] (1) The molar ratio is (1-a):2a:(1-b-c):2b:c, respectively weigh lanthanum oxide, strontium carbonate, gallium oxide, magnesium oxide, lithium carbonate, and prepare the mixture;

[0016] (2) Put the raw materials weighed according to the above proportions into a ball mill jar, use alcohol as the medium, and zirconia balls as the grinding medium, and mill for 20 to 30 hours;

[0017] (3) Dry the mixed powder after ball milling at 60-80°C, pass through a 200-mesh sieve after grinding, and place the sieved mixed powder at 800-1000°C for 1-3 hours to obtain electrolyte material powder ;

[0018] (4) Grind the above electrolyte powder throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com