Two-step micro-arc oxidation method for producing super wear-resistant coating on surface of aluminium alloy

A technology of micro-arc oxidation on the surface of aluminum alloy, applied in the field of electrochemistry, can solve the problems of slow film formation speed, low corundum composition, affecting the wear resistance of the film layer, etc., and achieve the effect of fast film formation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

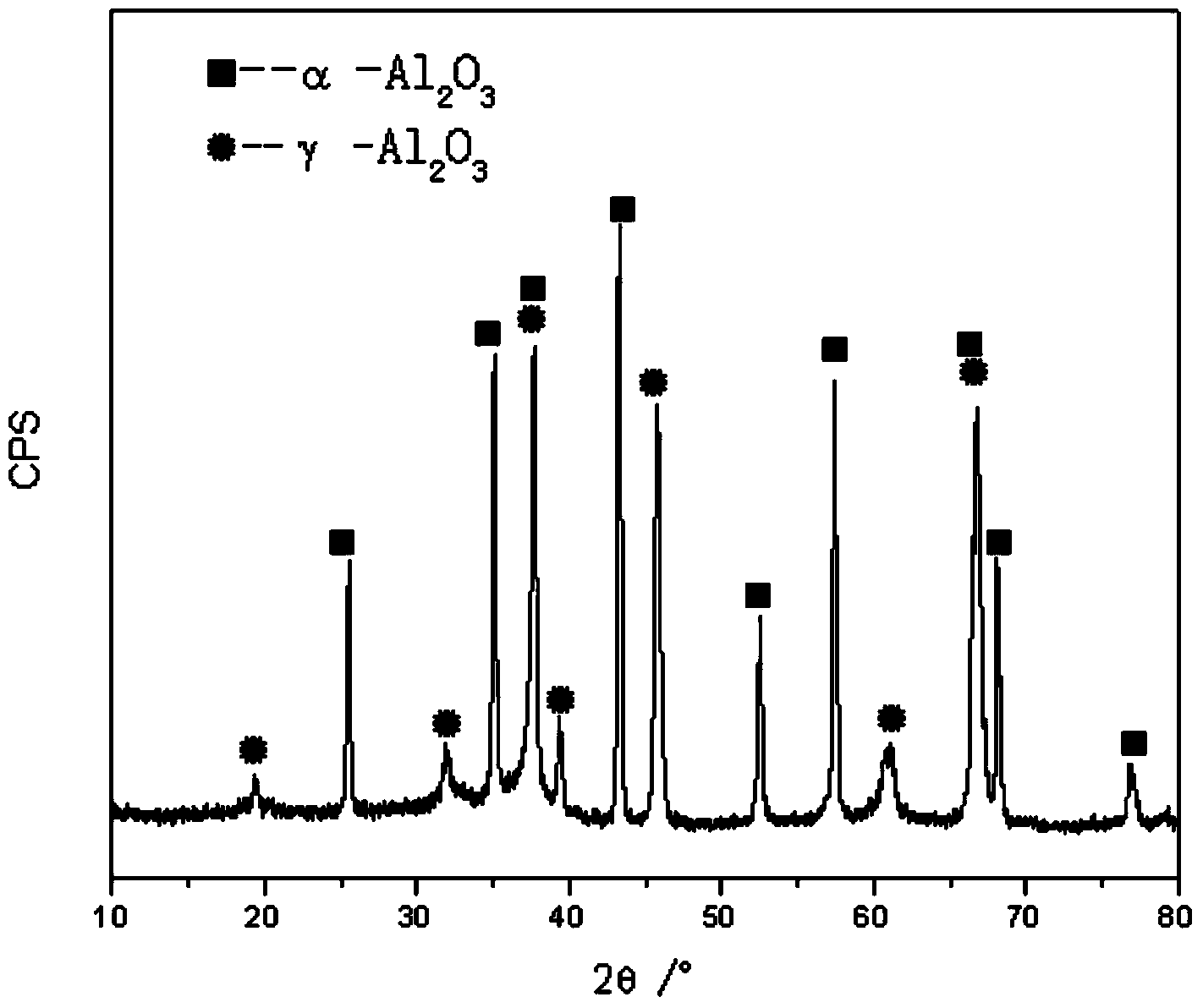

[0055] Example 1: two-step micro-arc oxidation

[0056] 1. Use E-44 epoxy resin to seal the area outside the working surface of the aluminum alloy substrate, polish the working surface of the aluminum alloy substrate with 60# to 2000# SiC sandpaper, and rinse the working surface with alcohol and deionized water respectively.

[0057] 2. One-step micro-arc oxidation treatment: use the substrate as the anode and the steel plate as the cathode, turn on the power, set the parameters of the micro-arc oxidation power supply, and the positive current is 25A / dm 2 , the negative current is set to (20) A / dm 2 , The positive and negative duty cycle is set to 20%, and the frequency is maintained at 1000Hz. The one-step electrolyte is composed of sodium aluminate and potassium hydroxide solution, wherein the concentration of aluminate is 10 g / L, and the concentration of potassium hydroxide is 1 g / L; after about 40 seconds of electrolysis (at this time, the cell voltage rises to about 45...

Embodiment 2

[0080] According to the method of embodiment 1, others are the same as embodiment 1, the parameter of micro-arc oxidation power supply is: positive current is 10A / dm 2 , the negative current is set to 10 A / dm 2 , the positive and negative duty cycle is set to 60%, the frequency is 500Hz, and NaAlO is used as described in the two-step micro-arc oxidation treatment 2 , = concentration is 45 g / L, treatment time is 5 min, the film thickness reaches 40 microns, the growth rate of the film layer increases, and the α-Al in the film 2 o 3 The content reaches 48%. The wear resistance can withstand the condition of 100 N friction time for 60 minutes.

Embodiment 3

[0082] According to the method of embodiment 1, others are the same as embodiment 1, and the current parameter is: the positive current is 40A / dm 2 , the negative current is set to 40A / dm 2 , The positive and negative duty cycle is set to 40%, and the frequency is 2000Hz; NaAlO is used as described in the two-step micro-arc oxidation treatment 2 , the concentration was 60 g / L, the treatment time was 5 min, the film thickness reached 50 microns, the growth rate of the film layer was further increased, and the α-Al in the film 2 o 3 content up to 55%. The wear resistance can also withstand the condition of 120 N rubbing time for 60 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wear scar depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com