Room temperature curing double-component waterborne polyurethane transparent thermal insulation coating material and preparation method thereof

A water-based polyurethane, room temperature curing technology, applied in the field of coatings, can solve the problems of harsh preparation conditions and complex heat treatment process, and achieve the effect of simple preparation process, excellent transparent heat insulation performance, and smooth film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

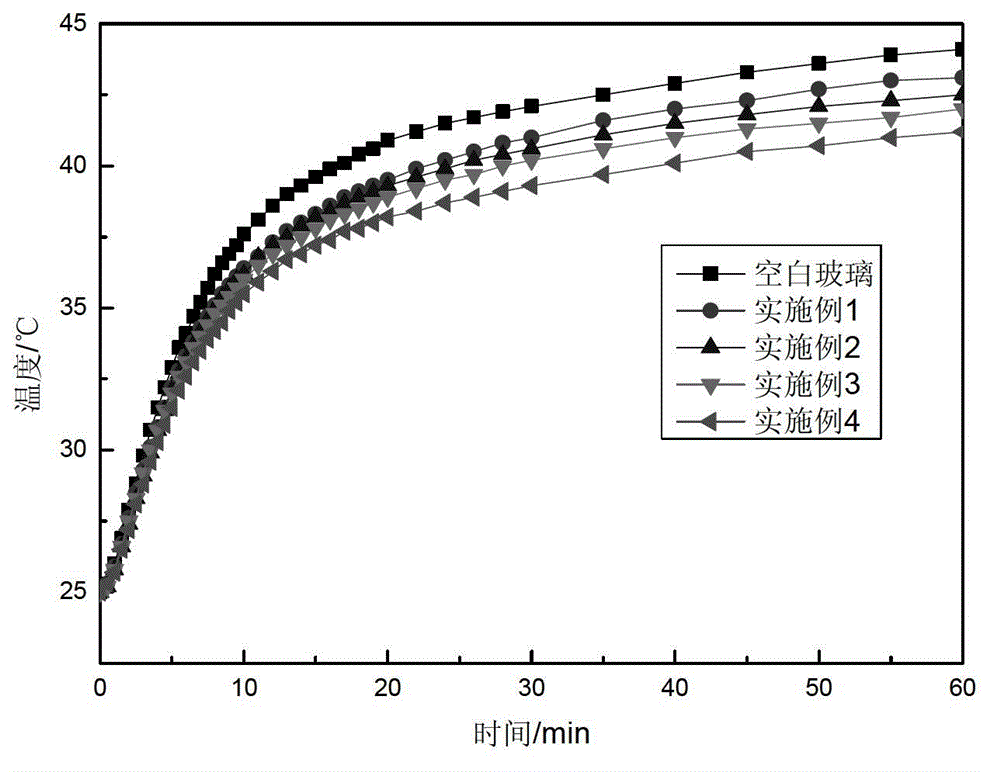

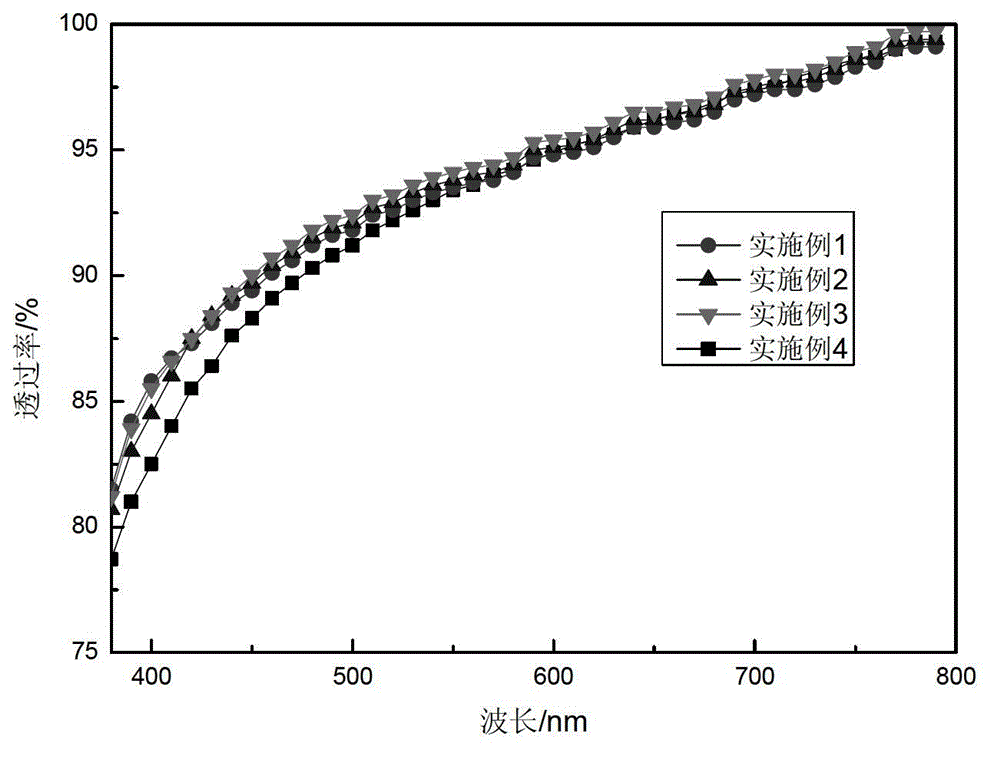

Embodiment 1

[0035] Weigh 1g of nano-ITO powder and 0.1g of polyethylene glycol-1000 into 50g of deionized water to adjust the pH of the system to 2, ultrasonicate for 10min, and then homogeneously disperse at high speed for 30min to obtain an aqueous ITO slurry. Weigh 100g of water-based polyurethane (PUD-350, Shanghai Sisheng), mix it evenly with water-based ITO slurry, add 0.5g of defoamer K-610, 1g of leveling agent FL-3 and 0.5g of thickener K in sequence -800, high-speed stirring and dispersing for 30 minutes to obtain component A of the coating; weigh 10g of water-based polyisocyanate curing agent and 20g of deionized water and stir evenly to obtain component B of the coating; slowly add component B to component A, Stir for 3-5 minutes until the coating is uniform and the viscosity is 3mPa·s.

Embodiment 2

[0037] Weigh 2g of nano-ITO powder and 0.5g of polyethylene glycol-1200 into 50g of deionized water, adjust the pH of the system to 3, ultrasonically treat for 10min, and disperse homogeneously at high speed for 30min to obtain an aqueous ITO slurry. Weigh 150g of water-based polyurethane (PUD-350, Shanghai Sisheng), mix it evenly with water-based ITO slurry, add 1g of defoamer K-610, 1.5g of leveling agent FL-3 and 0.8g of thickener K in sequence -800, high-speed stirring and dispersing for 30 minutes to obtain component A of the coating; weigh 20g of water-based polyisocyanate curing agent and 30g of deionized water and stir evenly to obtain component B of the coating; slowly add component B to component A, Stir for 3-5 minutes until the coating is uniform and the viscosity is 3mPa·s.

Embodiment 3

[0039] Weigh 4g of nano-ITO powder and 0.8g of polyvinylpyrrolidone into 50g of deionized water, adjust the pH of the system to 4, ultrasonically treat for 15min, and disperse homogeneously at high speed for 30min to obtain an aqueous ITO slurry. Weigh 150g of water-based polyurethane (PUD-350, Shanghai Sisheng), mix it evenly with water-based ITO slurry, add 1.5g of defoamer K-610, 2g of leveling agent FL-3 and 0.8g of thickener K -800, stir and disperse for 30 minutes to obtain component A of the coating; weigh 30g of water-based polyisocyanate curing agent and 30g of deionized water and stir evenly to obtain component B of the coating; slowly add component B to component A, stir 3 to 5 minutes until the coating is uniform and the viscosity is 5mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com