Making method of form-adjustable Mo/Zn film

A thin film and morphology technology, which is applied in the field of preparing solar cell copper zinc tin sulfur compound precursors, can solve the problems of limited large-scale production, complexity, expensive equipment, etc., and achieve environmental protection in the preparation process, short production cycle and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

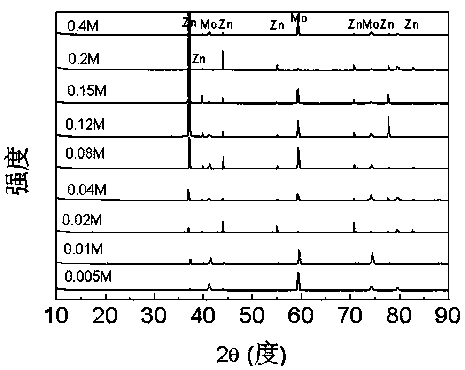

[0038] A method for preparing a Mo / Zn thin film with adjustable morphology, specifically comprising the steps of:

[0039] (1) Grind and polish a 1cm×1cm Mo sheet and make a Mo electrode;

[0040] (2) Prepare zinc chloride, potassium chloride and deionized water into a mixed aqueous solution containing zinc chloride and potassium chloride, adjust the pH value to 5 with boric acid, and use a three-electrode system, that is, use a platinum electrode as the counter electrode 1. The calomel electrode was used as the reference electrode and the Mo electrode was used as the working electrode. The Mo / Zn thin film was obtained by deposition at a constant potential of -1.3V for 1000s with an electrochemical workstation.

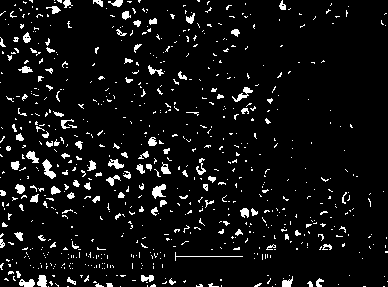

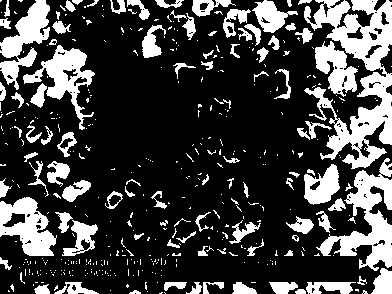

[0041] In the mixed aqueous solution containing zinc chloride and potassium chloride, the molar concentrations of zinc chloride are respectively 0.005mol / L, 0.01mol / L, 0.02mol / L, 0.04mol / L, 0.08mol / L, 0.12mol / L L, 0.15mol / L, 0.2mol / L and 0.4mol / L, the molar concentra...

Embodiment 2

[0045] A method for preparing a Mo / Zn thin film with adjustable morphology, comprising the steps of:

[0046] (1) Grind and polish a 1cm×1cm Mo sheet and make a Mo electrode;

[0047] (2), zinc chloride, potassium chloride, polyethylene glycol 6000 and deionized water were prepared into 3 parts of mixed aqueous solutions containing zinc chloride, polyethylene glycol 6000 and potassium chloride, and the pH value was adjusted with boric acid 5. Adopt a three-electrode system, that is, use a platinum electrode as a counter electrode, a calomel electrode as a reference electrode, and a Mo electrode as a working electrode, and use an electrochemical workstation to deposit a Mo / Zn film at a constant potential of -1.3V for 1000s;

[0048] Above-mentioned 3 parts contain in the mixed aqueous solution of zinc chloride, macrogol 6000 and potassium chloride, the molar concentration of zinc chloride is 0.02mol / L, and the molar concentration of potassium chloride is 0.25mol / L, poly The mo...

Embodiment 3

[0051] A method for preparing a Mo / Zn thin film with adjustable morphology, comprising the steps of:

[0052] (1) Grind and polish a 1cm×1cm Mo sheet and make a Mo electrode;

[0053] (2), zinc chloride, potassium chloride, polyethylene glycol 6000 and deionized water were prepared into 3 parts of mixed aqueous solutions containing zinc chloride, polyethylene glycol 6000 and potassium chloride, and the pH value was adjusted with boric acid 5. Adopt a three-electrode system, that is, use a platinum electrode as a counter electrode, a calomel electrode as a reference electrode, and a Mo electrode as a working electrode, and use an electrochemical workstation to deposit a Mo / Zn film at a constant potential of -1.3V;

[0054] Above-mentioned 3 parts contain in the mixed aqueous solution of zinc chloride, macrogol 6000 and potassium chloride, the molar concentration of zinc chloride is 0.12mol / L, and the molar concentration of potassium chloride is 2 mol / L, poly The molar concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com