Gelled acid used for acid fracturing of high-temperature fractured-vuggy type carbonate reservoir

A carbonate reservoir, fracture-cavity type technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problem of incomplete and perfect formula, weak acid viscosification ability, long time for on-site preparation, etc. problems, to achieve the effects of good compatibility and fluid loss control performance, short acid dissolution time, and reduced reservoir damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A thickening acid for acid fracturing of high-temperature fracture-cavity carbonate rock reservoirs, characterized in that the thickening acid comprises, by weight percentage: hydrochloric acid, 20%; thickening agent, 3%; corrosion inhibitor agent, 2%; iron ion stabilizer, 1.5%; demulsifier, 0.05%; drainage aid, 1.5%; the balance is water.

[0034] The preparation process is as follows: first dilute industrial hydrochloric acid to a concentration of 20%, then add 1.5% iron ion stabilizer FL4-7, 0.05% demulsifier PRJ, 1.5% Drainage aid AD12, then add 3% thickener TP-1, at room temperature, mix evenly and swell for about 2 hours, the thickener can be fully dissolved and thickened in the formula acid solution, finally add 2% Corrosion inhibitor MC50, made into thickened acid after fully stirring.

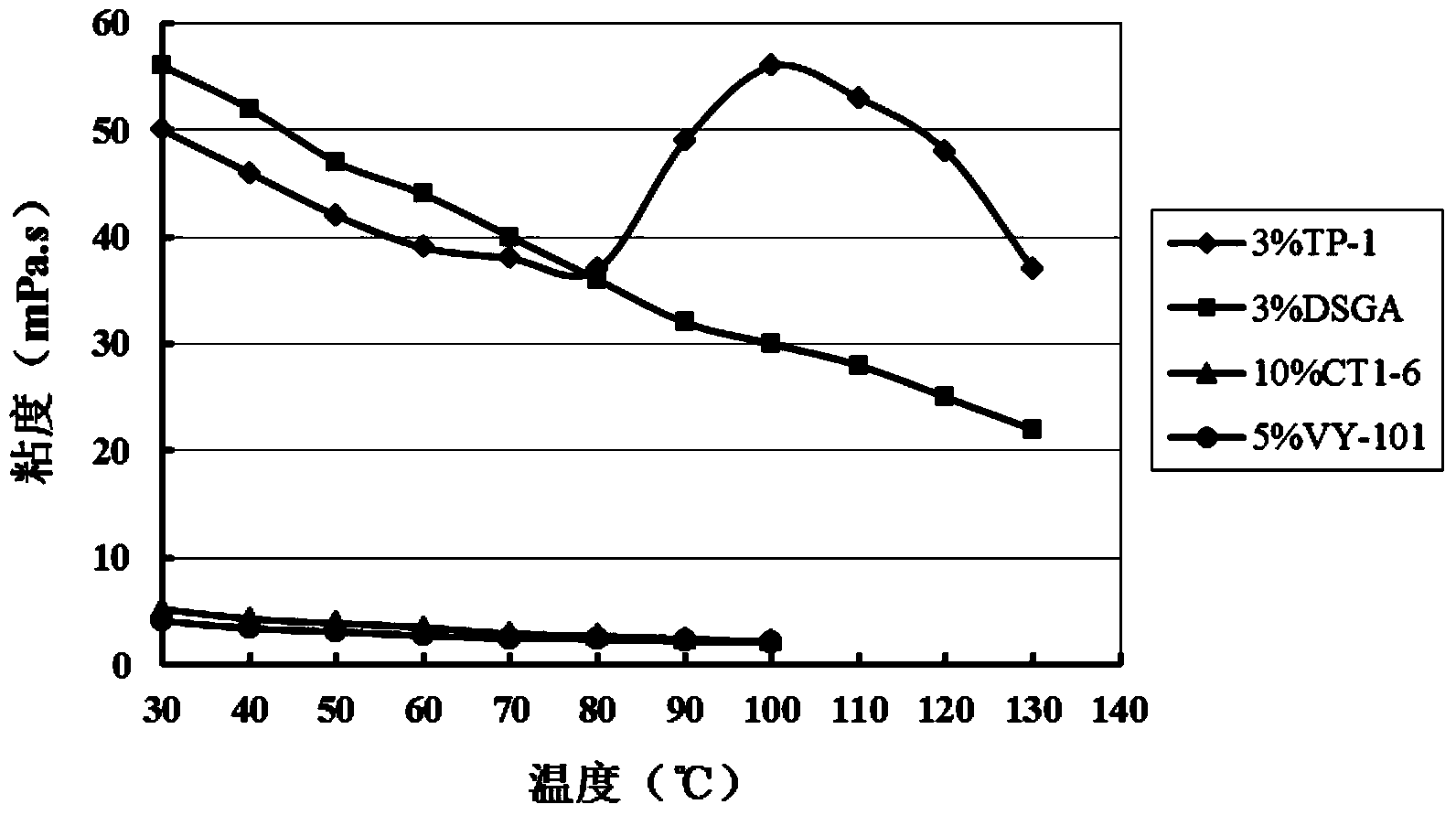

[0035] The selection of thickener is an important point in the preparation of thickened acid. figure 1 It shows the viscosity measurement curve of thickened acid (20% HCl) pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com