Catalyst system for alkene polymerization reaction

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalyst system and can solve the problems of different polymer properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

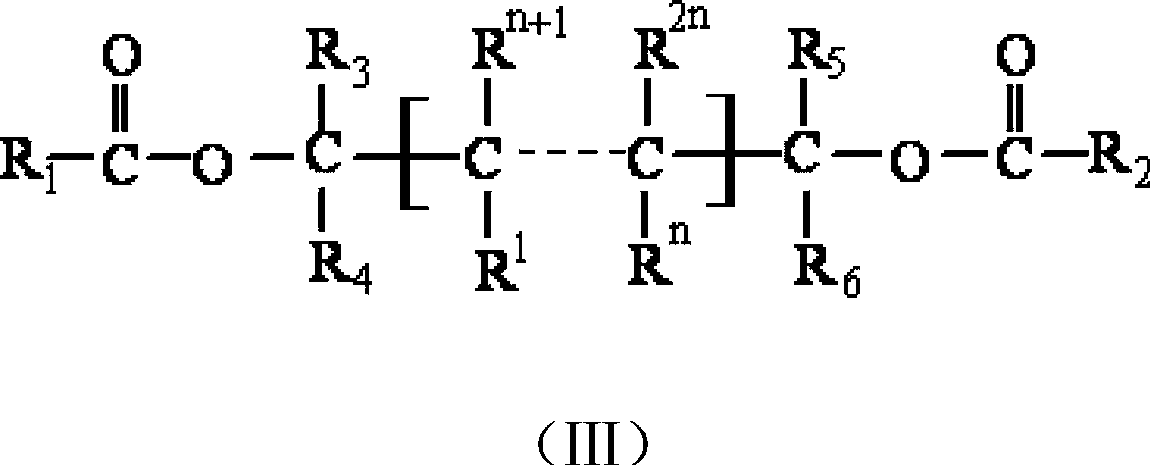

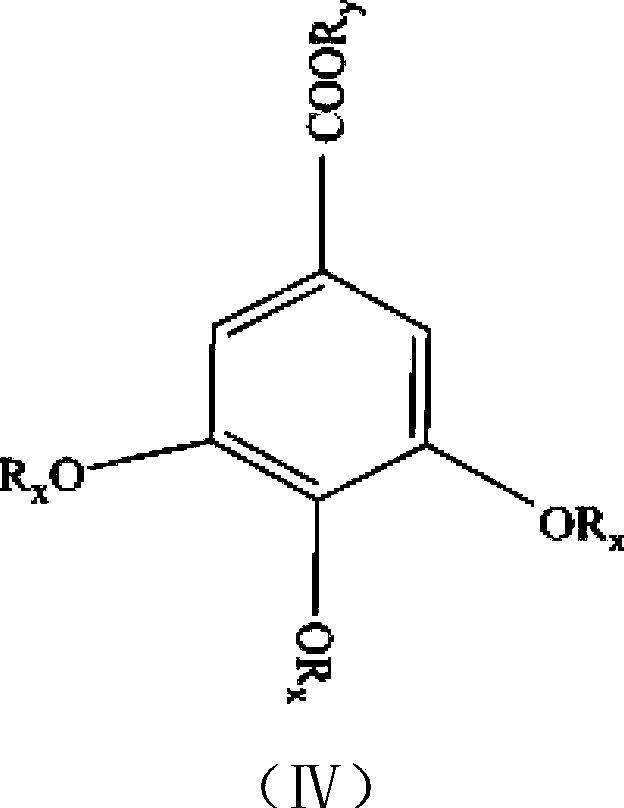

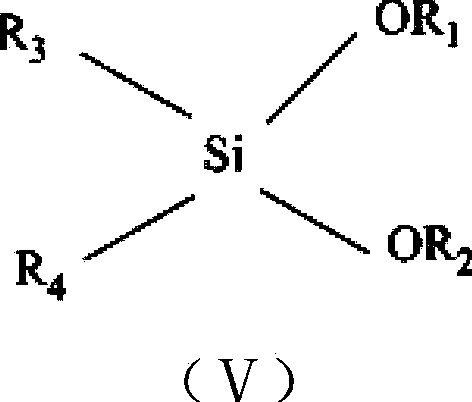

Method used

Image

Examples

Embodiment 1

[0060] Preparation of diol ester compound 2,4-pentanediol dibenzoate

[0061] (1) Preparation of 2,4-pentanediol

[0062] A mixture of 10g of 2,4-pentanedione and 30ml of methanol was added dropwise to a mixed solution of 2.5g of sodium borohydride, 0.1g of sodium hydroxide and 25ml of water at 0-10°C. After the addition, the solvent was removed under reduced pressure and extracted continuously with 40ml of ethyl acetate for 15h. The solvent was removed and column chromatography was used to obtain 2,4-pentanediol as a colorless liquid with a yield of 90%.

[0063] (2) Preparation of 2,4-pentanediol dibenzoate

[0064] Add 30ml tetrahydrofuran and 0.09mol pyridine to 0.03mol 2,4-pentanediol, add 0.075mol benzoyl chloride under stirring, and heat to reflux for 4h. After cooling, add 20ml of saturated brine, extract with ethyl acetate, anhydrous Na 2 SO 4 Dry and remove solvent. Column chromatography or vacuum distillation gave colorless liquid 2,4-pentanediol dibenzoate with...

Embodiment 2

[0077] 2A, preparation of titanium-containing solid catalyst component A

[0078] Add 100ml of titanium tetrachloride to a 300ml stirring glass reaction bottle fully replaced by high-purity nitrogen, cool to -20°C, add spherical magnesium chloride alcoholate (see Chinese patent CN1330086A for the preparation method), and slowly raise the temperature in stages To 110°C, add 2.5mmol of 2,4-pentanediol dibenzoate and 3.9mmol of dibutyl phthalate prepared in Example 1 during the heating process, and filter off after keeping the temperature at 110°C for 0.5h The liquid was treated twice with titanium tetrachloride, washed five times with hexane, and vacuum-dried to obtain titanium-containing solid catalyst component A (main catalyst).

[0079] 2B, bulk homopolymerization of propylene

[0080] In a 5-liter autoclave, use a nitrogen stream to purge at 70°C for 1 hour, then replace the polymerization vessel 3 times with gas-phase propylene, and introduce 5 ml of a hexane solution of ...

Embodiment 3~10

[0093] The polymerization results obtained by compounding the solid catalyst prepared in 2A of Example 2 according to the method of propylene polymerization in 2B of Example 2 according to different amounts of hydrogenation and different additions of external electron donors. Polymerization and test results are shown in Table 1 and Table 2, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com