Wastewater reuse method combining magnetic loading coagulation clarification and membrane separation

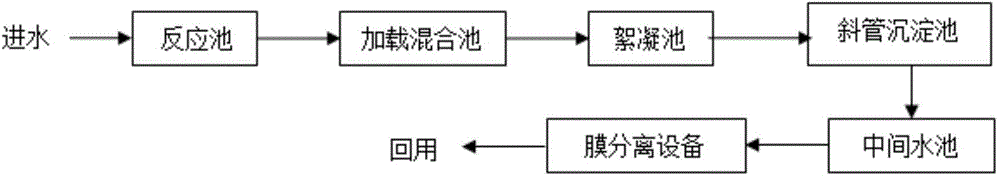

A membrane separation, magnetic loading technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low removal rate of dissolved pollutants in water and high investment and operation costs , to achieve the effect of thorough treatment, avoiding the degree of membrane pollution and improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

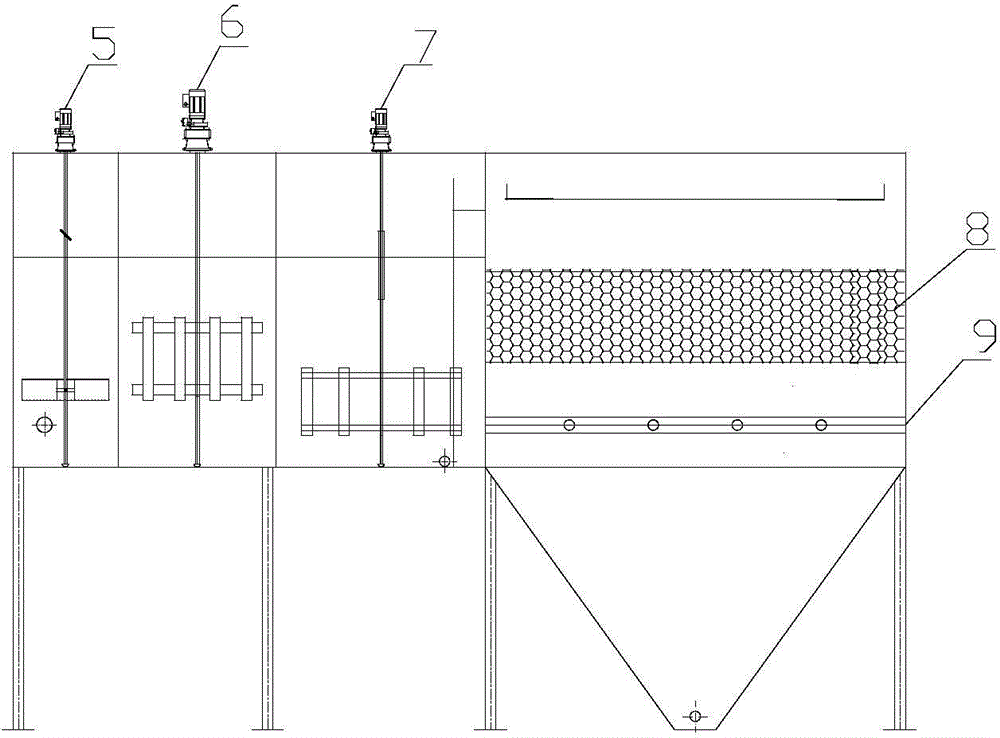

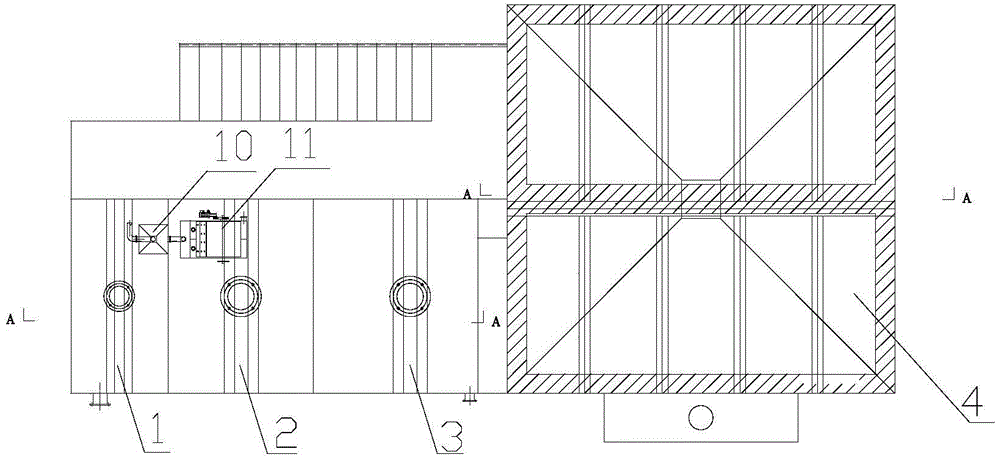

Image

Examples

Embodiment 1

[0036] The volume of wastewater after biochemical treatment in a printing and dyeing factory is 2000 tons / day, COD is 191mg / L, turbidity is 19.38NTU, suspended matter is 70mg / L, and iron ion is 0.78mg / L.

[0037] The wastewater is lifted into the reaction tank by the centrifugal pump, and 80mg / L of polyaluminum chloride coagulant is added to the reaction tank, and fine flocs are generated under the stirring of the double-layer paddle mixer in the reaction tank at a speed of 73r / min, and the wastewater in the mixing tank is loaded The mixing adopts a single-layer frame mixer with a speed of 43r / min. The fine flocs produced in the reaction tank and the magnetite powder recovered by the magnetic drum separator form dense magnetic nuclei with colloidal properties under the action of the hydraulic mixing speed gradient .

[0038] Add 2 g / ton of polyacrylamide flocculant in the flocculation tank and generate large-particle magnetic flocs under the slow stirring of the double-layer f...

Embodiment 2

[0041] The average influent COD of a city sewage treatment plant is 350mg / L, the average suspended solids is 310mg / L, and the average total phosphorus is 6.8mg / L.

[0042] The wastewater is lifted into the reaction tank, and 300 mg / L of polyaluminum chloride coagulant is added to the reaction tank, and fine flocs are formed under the stirring of the double-layer paddle mixer in the reaction tank at a speed of 85 r / min, and the wastewater is mixed in the loading mixing tank using Single-layer frame mixer with a rotating speed of 37r / min. The fine flocs produced in the reaction tank and the magnetite powder recovered by the magnetic drum separator form dense magnetic nuclei with colloidal properties under the action of hydraulic mixing speed gradient.

[0043] Add 3 g / ton of polyacrylamide flocculant in the flocculation tank and generate large-particle magnetic flocs under the double-layer frame mixer at a slow speed of 15r / min, and then evenly flow into the sedimentation tank th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com