Pretreatment method for fluorenone production wastewater

A technology for the production of waste water and pretreatment, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve problems affecting treatment work and increase investment costs, and achieve equipment investment savings , Improve biodegradability and protect the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

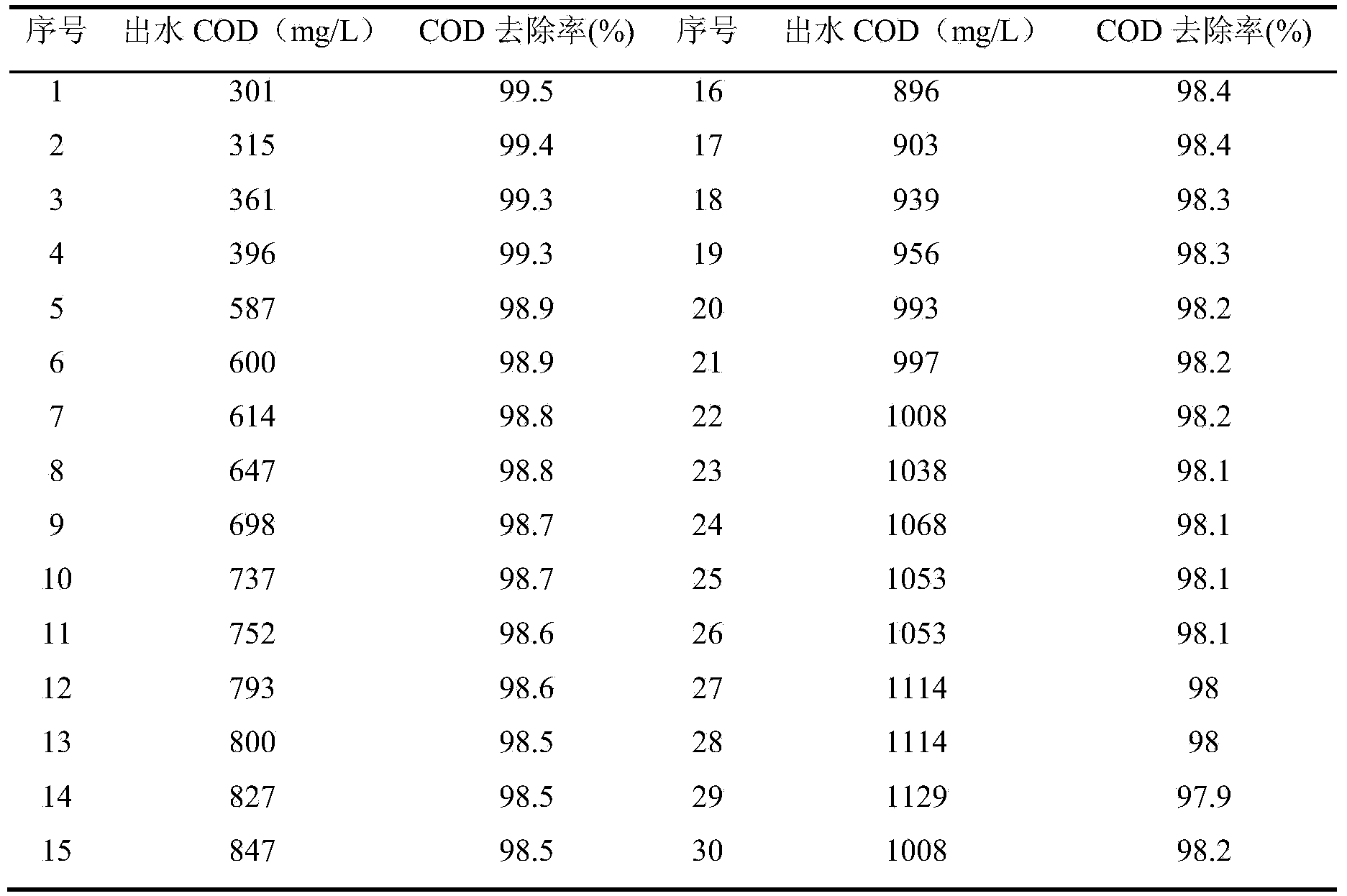

Embodiment 1

[0020] Take 500L of fluorenone production wastewater, slowly add 92.5% industrial concentrated sulfuric acid to it for acid analysis, until the pH is adjusted to 3, after fully stirring, let it stand for stratification, the oil phase is recovered for production process use, and the water phase after acid analysis is as follows: Add 12.5L of H with a mass concentration of 30% per 500L 2 o 2 and 1kg of FeSO 4 ·7H 2 O, add 7.5kg of activated carbon to it at the same time, turn on the stirring and raise the temperature to 55°C, and take a sample test after timing the reaction for 60 minutes. The COD of the effluent can reach 580mg / L, the COD removal rate can reach 98.9%, and the B / C value increases from 0.2 to 0.55. After the effluent is subjected to SBR biochemical treatment, the final effluent COD can reach 45mg / L, which is better than the first-level discharge standard in the "Integrated Wastewater Discharge Standard" (GB8978-1996).

Embodiment 2

[0022] Take 500L of fluorenone production wastewater, slowly add 92.5% industrial concentrated sulfuric acid to it for acid analysis, until the pH is adjusted to 2, after fully stirring, let it stand for stratification, the oil phase is recovered and used in the production process, and the water phase is used after acid analysis. Add 25L of 30% H for every 500L 2 o 2 and 1.5kg of FeSO 4 ·7H 2 O, add 15kg of activated carbon to it at the same time, start the stirring and raise the temperature to 45°C, take a sample test after timing the reaction for 30 minutes, the COD of the effluent can reach 848mg / L, the COD removal rate can reach 98.5%, and the B / C value increases from 0.2 to 0.46. After the effluent is treated with SBR biochemical treatment, the final effluent COD can reach 65mg / L, which is better than the first-level discharge standard in the "Integrated Wastewater Discharge Standard" (GB8978-1996).

Embodiment 3

[0024] Take 500L of fluorenone production wastewater, slowly add 98% industrial concentrated sulfuric acid to it for acid analysis, until the pH is adjusted to 1, after fully stirring, let it stand for stratification, and the oil phase is recovered for use in the production process. After acid analysis, the water phase is Add 30L of 30% H for every 500L 2 o 2 and 2.5kg of FeSO 4 ·7H 2 O, add 15kg of activated carbon to it at the same time, turn on the stirring and raise the temperature to 35°C, take a sample test after timing the reaction for 120min, the effluent COD can reach 752mg / L, the COD removal rate can reach 98.6%, and the B / C value increases from 0.2 to 0.4. After the effluent is subjected to SBR biochemical treatment, the final effluent COD can reach 73mg / L, which is better than the first-level discharge standard in the "Integrated Wastewater Discharge Standard" (GB8978-1996).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com