Carbon resistance superfine nano wolfram carbide material as well as preparation method and application thereof

A technology of ultra-fine nanometer and tungsten source, applied in chemical instruments and methods, carbide, nanotechnology, etc., can solve the problems of particle agglomeration and large particle size, and achieve uniform particle size distribution, catalyst performance improvement, catalytic efficiency and performance Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

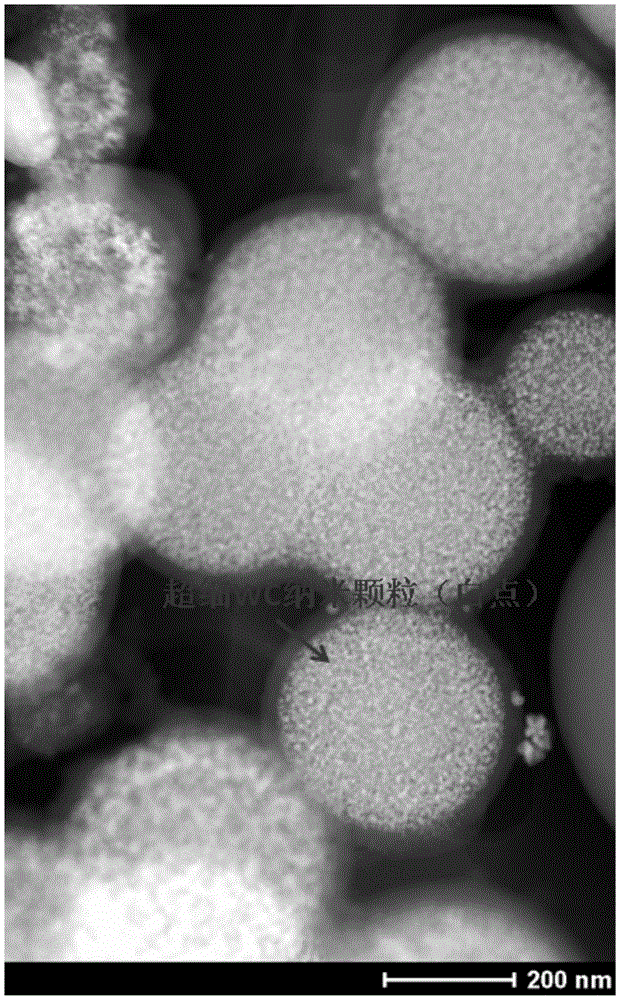

[0035] Add 0.08g of ammonium metatungstate to 50ml of distilled water and mix it with a solution made of 25ml of ethanol, 0.2ml of concentrated ammonia solution and 0.05g of sodium dodecylbenzenesulfonate. After stirring, add 0.5g of resorcinol and stir After 30 minutes, 0.5ml of formaldehyde was added, stirred at room temperature for 24 hours, then transferred to a hydrothermal reaction kettle and kept in a blast drying oven at 120°C for 15 hours, and the obtained compound was dried in a blast drying oven at 80°C. In the high-temperature tube furnace, the carbonization gas is 200ml / min of CO gas, raised from room temperature to 400°C at a rate of 5°C / min, kept at 400°C for 1 hour, and then heated to 900°C at the same heating rate for 6 hours. After cooling to room temperature, the obtained powder is the carbon resistance ultrafine nano WC material. It looks like figure 1 . WC components dispersed well, but partly showed agglomeration phenomenon. The particle size of highly...

Embodiment 2

[0037]Add 0.02g of ammonium metatungstate to 10ml of distilled water and mix it with a solution made of 5ml of ethanol, 0.05ml of concentrated ammonia solution and 0.005g of sodium dodecylbenzenesulfonate. After stirring, add 0.1g of resorcinol and stir After 30 minutes, 0.1ml of formaldehyde was added, stirred at room temperature for 8 hours, then transferred to a hydrothermal reaction kettle and kept in a blast oven at 80°C for 12 hours, and the obtained polymer was dried in a blast oven at 80°C. In the high-temperature tube furnace, the carbonization gas is 50ml / min of CO gas, raised from room temperature to 400°C at a rate of 1°C / min, kept at 400°C for 1 hour, and then heated to 900°C at the same heating rate for 2 hours. After cooling to room temperature, the obtained powder is the carbon resistance ultra-fine nano-WC material, but the output is less. The particle size of WC is about 2nm.

Embodiment 3

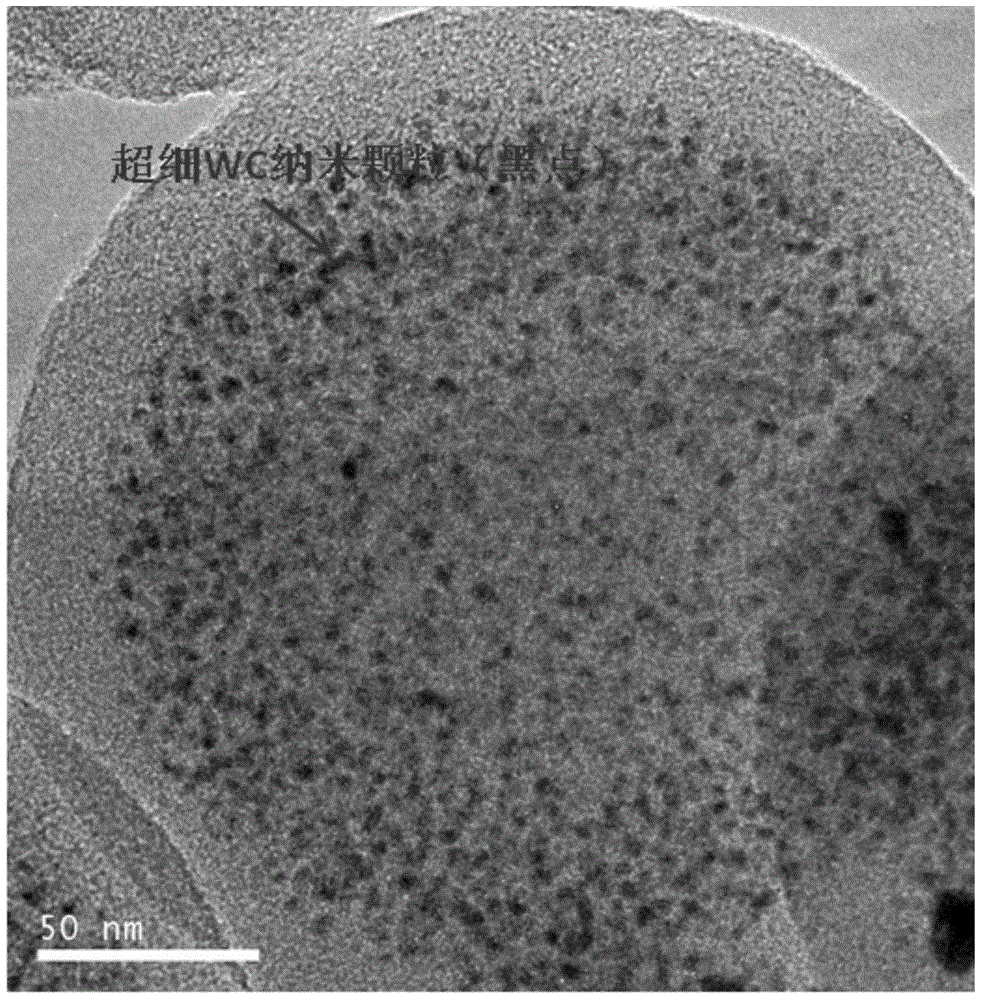

[0039] Add 0.02g of ammonium metatungstate to 20ml of distilled water and stir, then add to the solution made of 8ml of ethanol, 0.1ml of concentrated ammonia solution and 0.01g of sodium dodecylbenzenesulfonate, stir and add 0.25g of resorcinol and stir After 30 minutes, 0.35ml of formaldehyde was added, stirred at room temperature for 24 hours, then transferred to a hydrothermal reaction kettle and kept in a blast drying oven at 100°C for 12 hours, and the obtained polymer was dried in a blast drying oven at 80°C. In a high-temperature tube furnace, the temperature rises from room temperature to 400°C at a rate of 2.5°C / min, and the carbonization gas is 150ml / min of CO gas. After keeping at 400°C for 1 hour, it is heated to 900°C at the same heating rate for 4 hours. After cooling to room temperature, the obtained powder is the carbon resistance ultrafine nano WC material. It looks like figure 2 . The carbon component particle size reaches 250nm. The particle size of WC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com