Hydrogenation reaction effluent air cooler suitable for high chlorine raw oil processing

A technology of hydrogenation reaction and raw oil, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of equipment manufacturing cost increase, multi-phase flow stratification, and the effect of washing ammonium salt cannot be achieved and other problems to achieve the effect of prolonging the service life, avoiding deposition and under-deposit corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

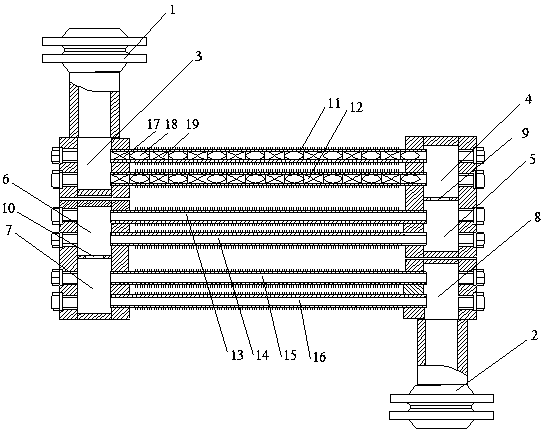

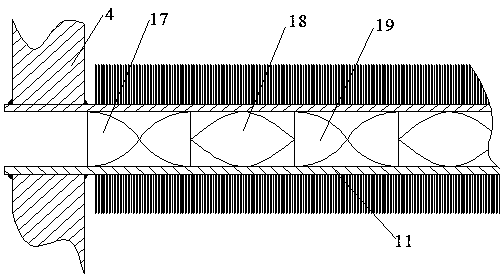

[0019] Such as figure 1 , figure 2 As shown, the present invention includes inlet flange 1, outlet flange 2, first tube box 3, second tube box 4, third tube box 5, fourth tube box 6, fifth tube box 7, sixth tube box 8. The first row of tube bundles 11, the second row of tube bundles 12, the third row of tube bundles 13, the fourth row of tube bundles 14, the fifth row of tube bundles 15, the sixth row of tube bundles 16, the first orifice plate 9, the second orifice plate 10, The first twisted sheet 17 and the second twisted sheet 18; the first tube box 3 and the second tube box 4 communicate through the first row of tube bundles 11 and the second row of tube bundles 12 arranged side by side, the second tube box 4 and the third tube bundle The boxes 5 are communicated through the first orifice plate 9, the third tube box 5 and the fourth tube box 6 are connected thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com