Micro-channel reactor

A microchannel reactor, microchannel technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve problems such as leakage at joints, and avoid leakage. leakage, increase the reaction rate, and increase the effect of the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the positive significance of the present invention, the content of the invention will be described in detail below in conjunction with the specific description, drawings and specific implementation.

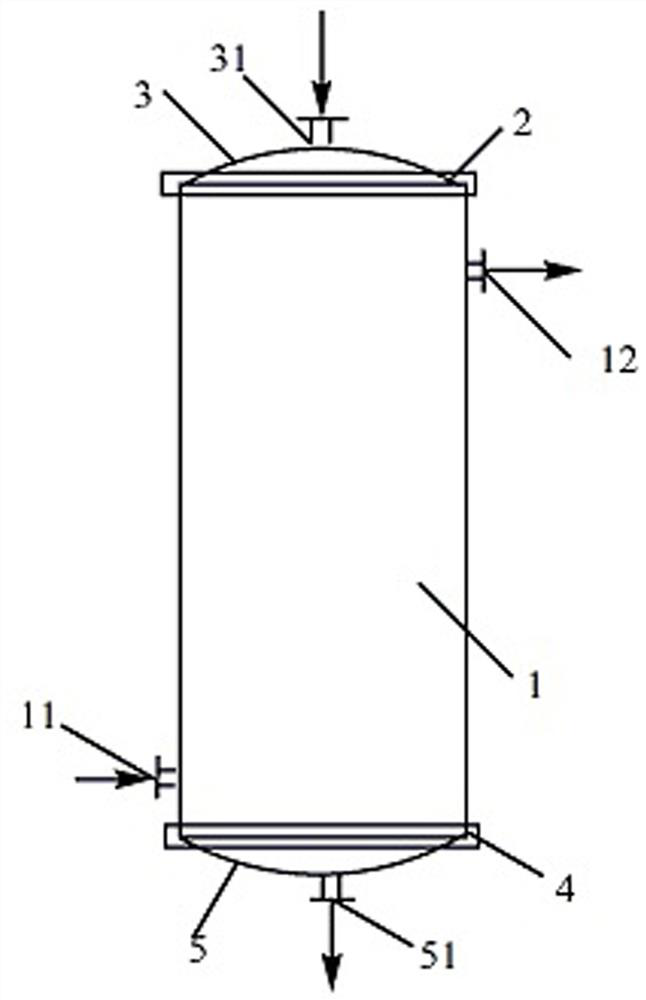

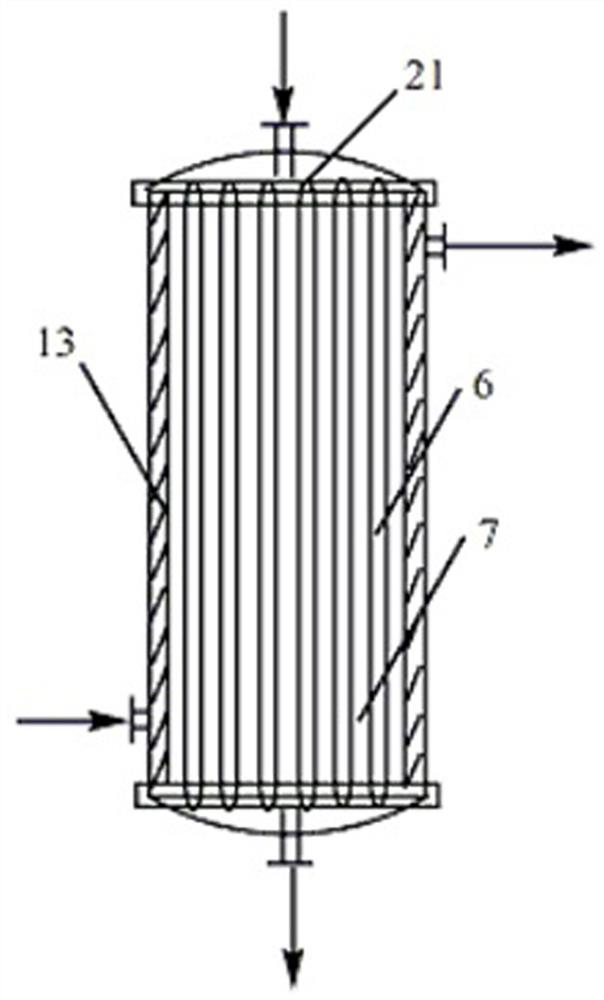

[0022] Microchannel reactor, upper end cover 3, upper end guide plate 2, reactor shell 1, lower end guide plate 4, lower end cover 5, micro reaction channel and other parts.

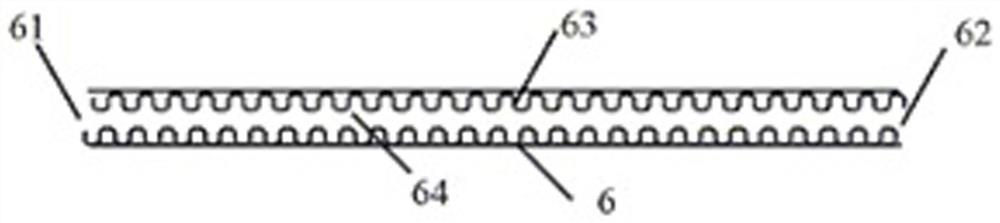

[0023] The upper and lower flow guide plates, the upper and lower end covers and the reactor shell 1 are connected by screwing or welding to form a closed overall structure; the upper flow guide plate 2 and the upper end cover 3, the lower end flow guide plate 4 and the The lower end caps 5 are connected by flanges. The upper and lower deflector pads and the reactor shell 1 enclose the heat-conducting medium cavity, and the micro-reaction channel tube bundles formed in parallel are immersed in the heat-conducting medium cavity. It can realize fast and direct heat trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com