Novel foam dedusting agent for coal mine

A dust collector and a new type of technology, applied in the fields of dust prevention, mining equipment, safety devices, etc., can solve the problems of high concentration dust, unsatisfactory effect, and threat to the service life of healthy underground equipment, so as to improve dust suppression efficiency, foam stability, Strong foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

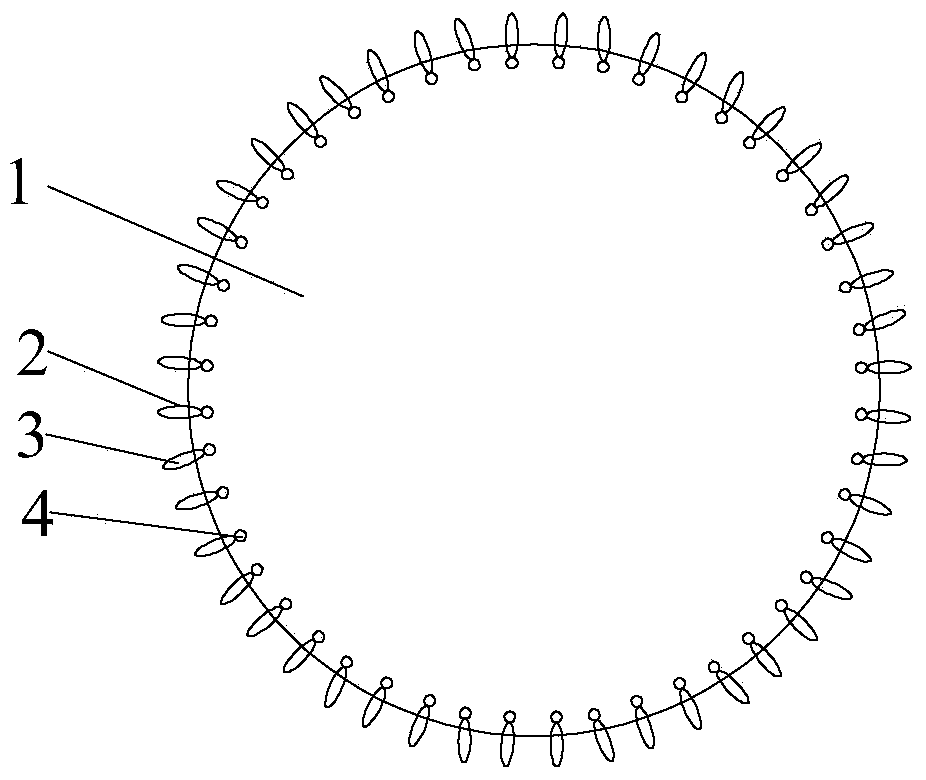

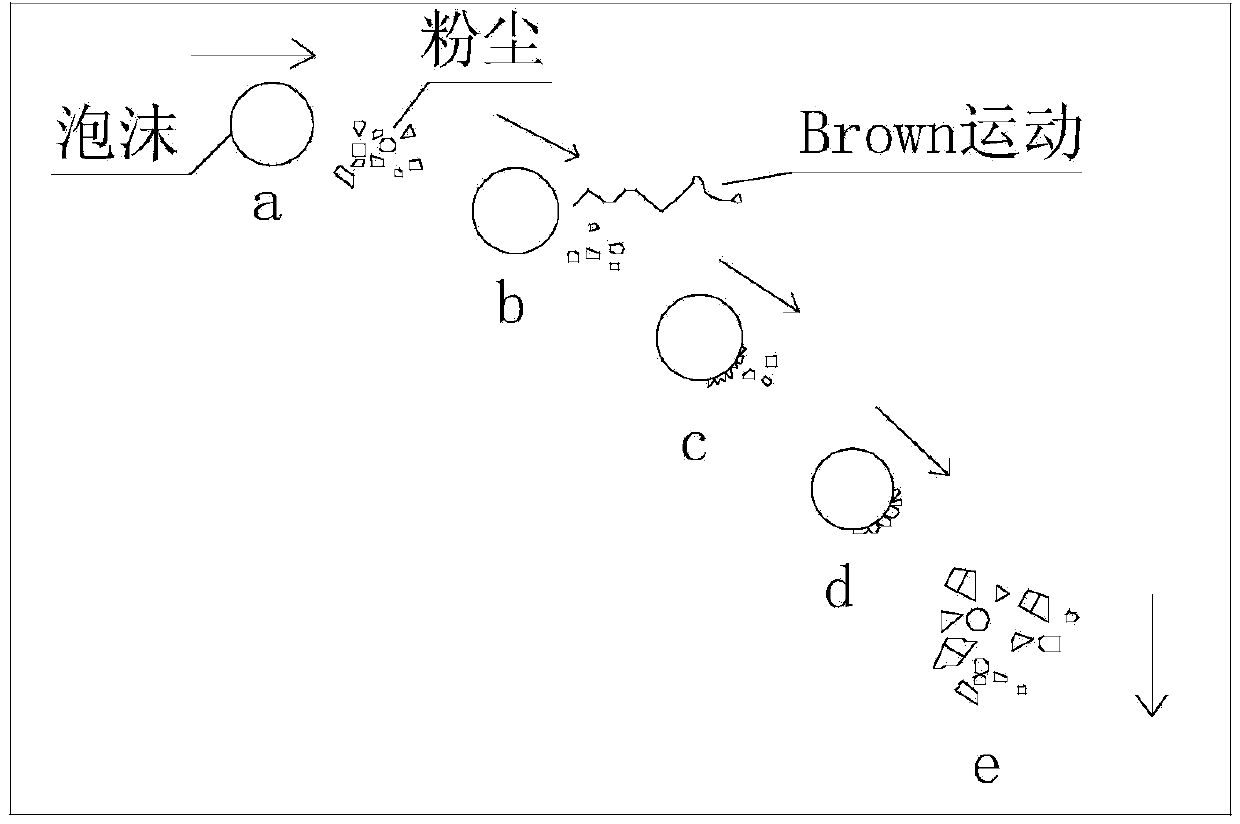

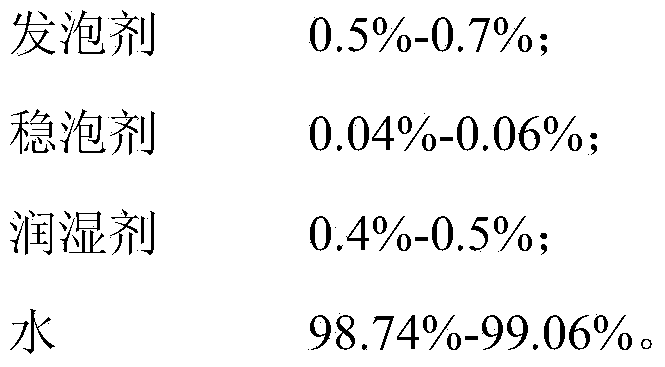

[0020] Take 6kg of modified alkyl glucoside, 0.4kg of carboxymethyl cellulose, and 5kg of alkylphenol polyoxyethylene ether, add them into 988.6kg of water, mix thoroughly, heat for a while to dissolve completely, and finally configure 1000kg of new foam dust remover. In the foam dust remover, the proportion of modified alkyl glucoside is 0.6%, the proportion of carboxymethyl cellulose is 0.04%, and the proportion of alkylphenol polyoxyethylene ether is 0.5%. Its specific dust reduction principle, such as figure 1 and figure 2 As shown, the prepared foam dedusting agent is added to the mine foam generator, and the generated foam is transported to the dust source to cover the dust source to achieve a good dust reduction effect. The total dust reduction rate of this formula can reach 96.58 %, the exhalation and dust reduction rate can reach 86.74%.

Embodiment 2

[0022] Take 7kg of modified alkyl glucoside, 0.6kg of carboxymethyl cellulose, and 4kg of alkylphenol polyoxyethylene ether, add them into 988.4kg of water, mix thoroughly, heat for a while to dissolve completely, and finally configure 1000kg of new foam dust remover. In the foam dust remover, the proportion of modified alkyl glucoside is 0.7%, the proportion of carboxymethyl cellulose is 0.06%, and the proportion of alkylphenol polyoxyethylene ether is 0.4%. Add the prepared foam dedusting agent into the mine foam generator, transport the generated foam to the dust source and cover the dust source to achieve a good dust reduction effect. The total dust reduction rate of this formula can reach 95.96%, and the dust removal The dust reduction rate can reach 85.67%.

Embodiment 3

[0024] Take 5 kg of modified alkyl glucoside, 0.5 kg of carboxymethyl cellulose, and 5 kg of alkylphenol polyoxyethylene ether, add them to 989.5 kg of water, mix thoroughly, heat for a while to dissolve completely, and finally configure 1000 kg of new foam dust remover. In the foam dust remover, the proportion of modified alkyl glucoside is 0.5%, the proportion of carboxymethyl cellulose is 0.05%, and the proportion of alkylphenol polyoxyethylene ether is 0.5%. Add the prepared foam dedusting agent into the mine foam generator, transport the generated foam to the dust source and cover the dust source to achieve a good dust reduction effect. The total dust reduction rate of this formula can reach 96.32%. The dust reduction rate can reach 85.93%.

[0025] The field application results are shown in the table below:

[0026] Table 1 The on-site dust concentration of the working face when no dust suppression measures are used

[0027]

[0028] Table 2 On-site dust concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com