Moistening agent for coal mine spray and dust reduction and preparation method

A technology of spraying dust reduction and wetting agent, which is applied in the fields of dust suppression and mine dust prevention. It can solve the problems of difficult degradation of surfactants, secondary environmental pollution, and poor dust suppression effect, so as to avoid secondary pollution and enhance wetting ability. , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

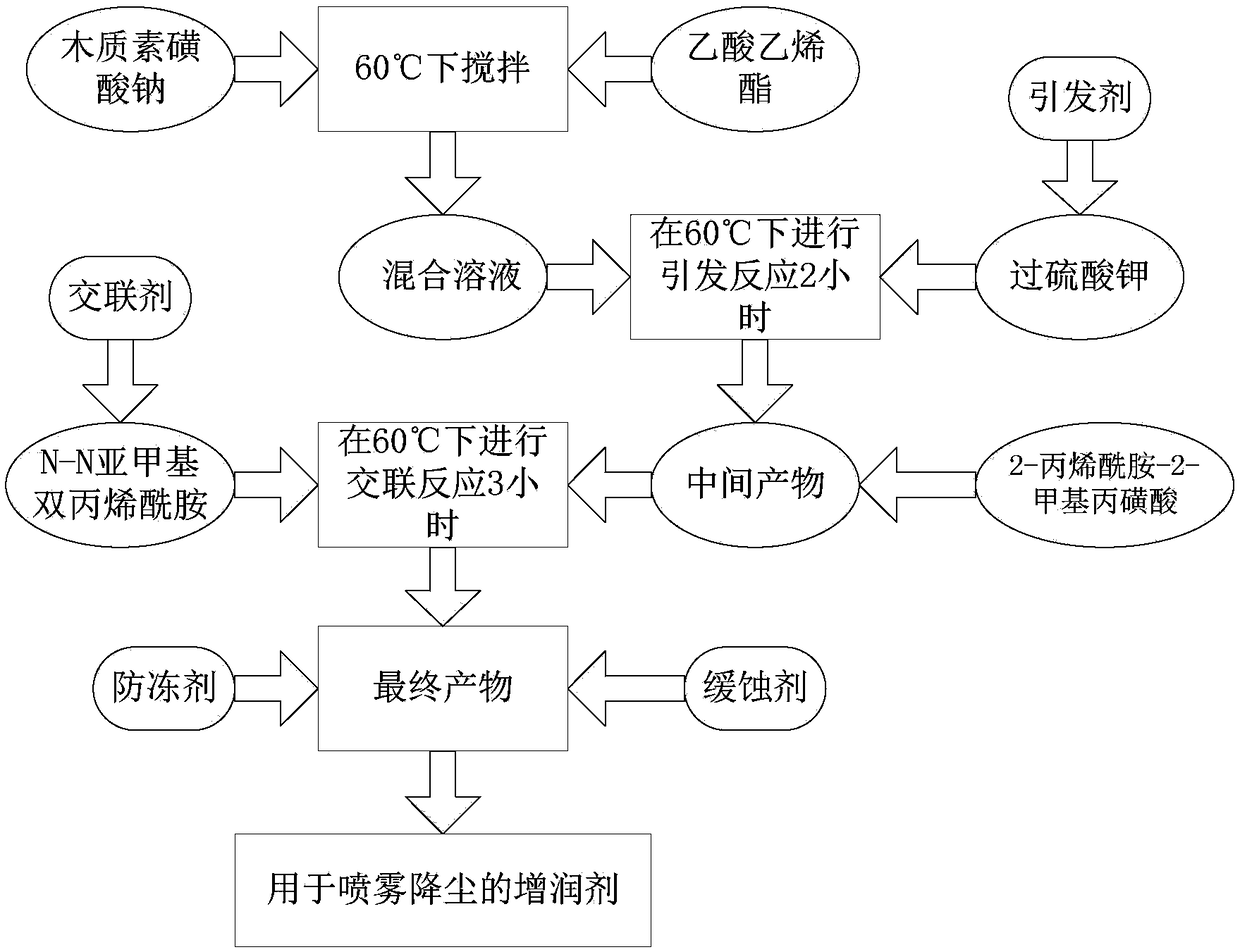

[0024] The present invention also provides a kind of preparation method of above-mentioned wetting agent, such as figure 1 As shown, it includes the following steps:

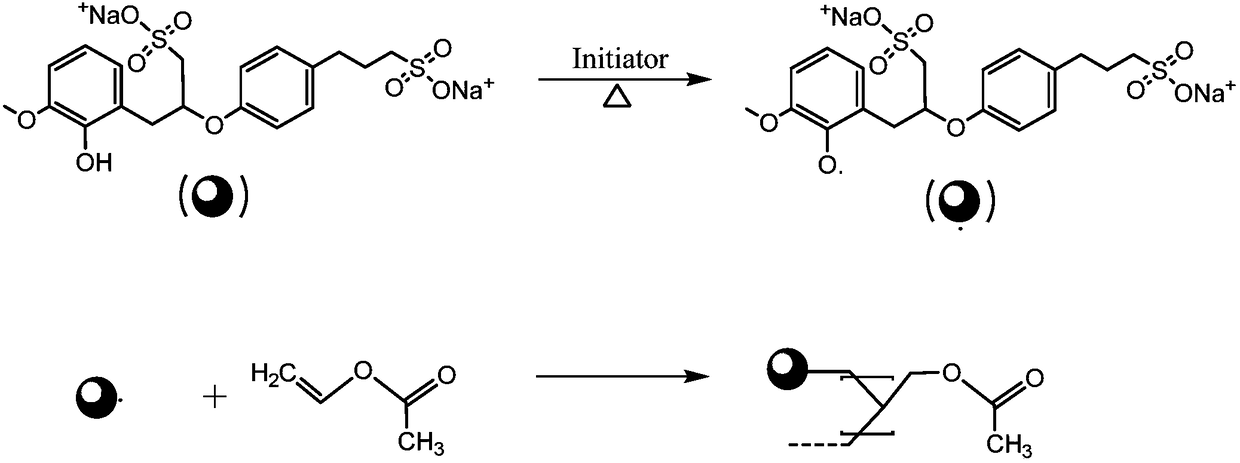

[0025] Step 1, after dissolving the lignosulfonate in water, add vinyl acetate, set the temperature of the constant temperature stirrer to 60°C and stir for 30 minutes, and then add the initiator to the above solution after fully dissolving and mixing. React at 60°C for 2 hours to obtain the first solution;

[0026]

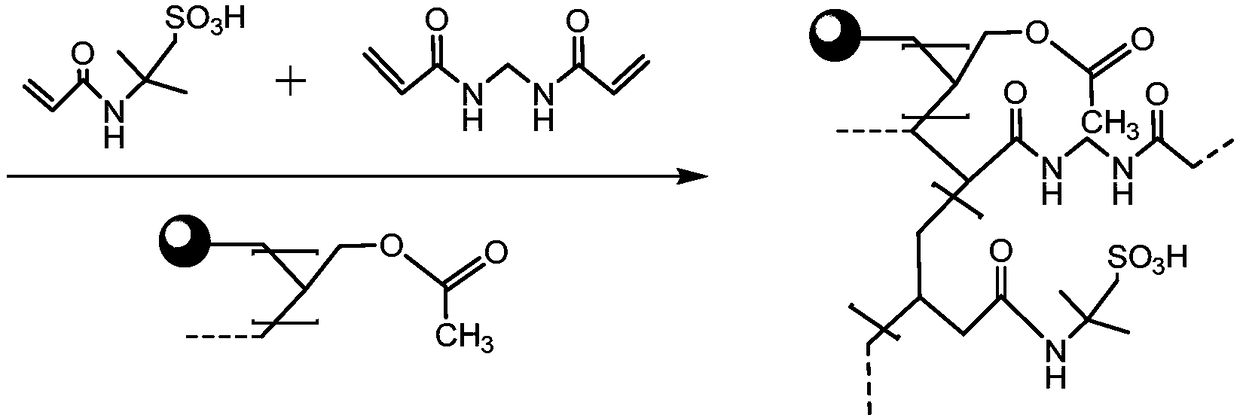

[0027] Step 2, adding 2-acrylamide-2-methylpropanesulfonic acid and a crosslinking agent to the first solution to continue the reaction for 1 hour to obtain the final product;

[0028]

[0029] Step 3: Add antifreeze and corrosion inhibitor to the final product, stir thoroughly and evenly, and adjust the pH value to obtain the above-mentioned wetting agent.

Embodiment 1

[0032] Weigh 2g of sodium lignosulfonate and 4ml of vinyl acetate and dissolve them in 200ml of water. After fully dissolving and stirring for 30 minutes, add 0.5g of ammonium persulfate to the solution, and react at a constant temperature of 60°C for 2 hours. Add 2 g of 2-acrylamide-2-methylpropanesulfonic acid and 0.5 g of N-N methylenebisacrylamide to the solution, keep stirring at 60° C. for 2 hours. After the reaction is completed, add 0.3g calcium chloride and 0.2ml phosphorus carboxylic acid to the solution to adjust the pH, take 2ml and 0.2g dodecyl dimethyl betaine and add it into 1L water and mix evenly, and test the relevant properties.

Embodiment 2

[0034] Weigh 2g of sodium lignosulfonate and 4ml of vinyl acetate and dissolve them in 200ml of water. After fully dissolving and stirring for 30 minutes, add 0.5g of ammonium persulfate to the solution, and react at a constant temperature of 60°C for 2 hours. Add 4 g of 2-acrylamide-2-methylpropanesulfonic acid and 0.5 g of N-N methylenebisacrylamide to the solution, keep stirring at 60° C. for 2 hours. After the reaction is completed, add 0.3g calcium chloride and 0.2ml phosphorus carboxylic acid to the solution to adjust the pH, take 2ml and 0.2g dodecyl dimethyl betaine and add it into 1L water and mix evenly, and test the relevant properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com