Braze welding nickel base impregnated diamond bit for deep part solid rock drilling, and manufacturing method of braze welding nickel base impregnated diamond bit

A diamond-impregnated and diamond-impregnated technology, which is applied in the field of brazed nickel-based diamond-impregnated drill bits and its manufacture, and the field of brazed nickel-based diamond-impregnated drill bits for deep hard rock drilling and its manufacture, which can solve the problem of low penetration rate of drill bits , Hinder the development of wireline coring drilling technology, short life and other problems, to achieve the effect of reducing the cost of the drill bit, prolonging the life of the drill bit, and improving the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

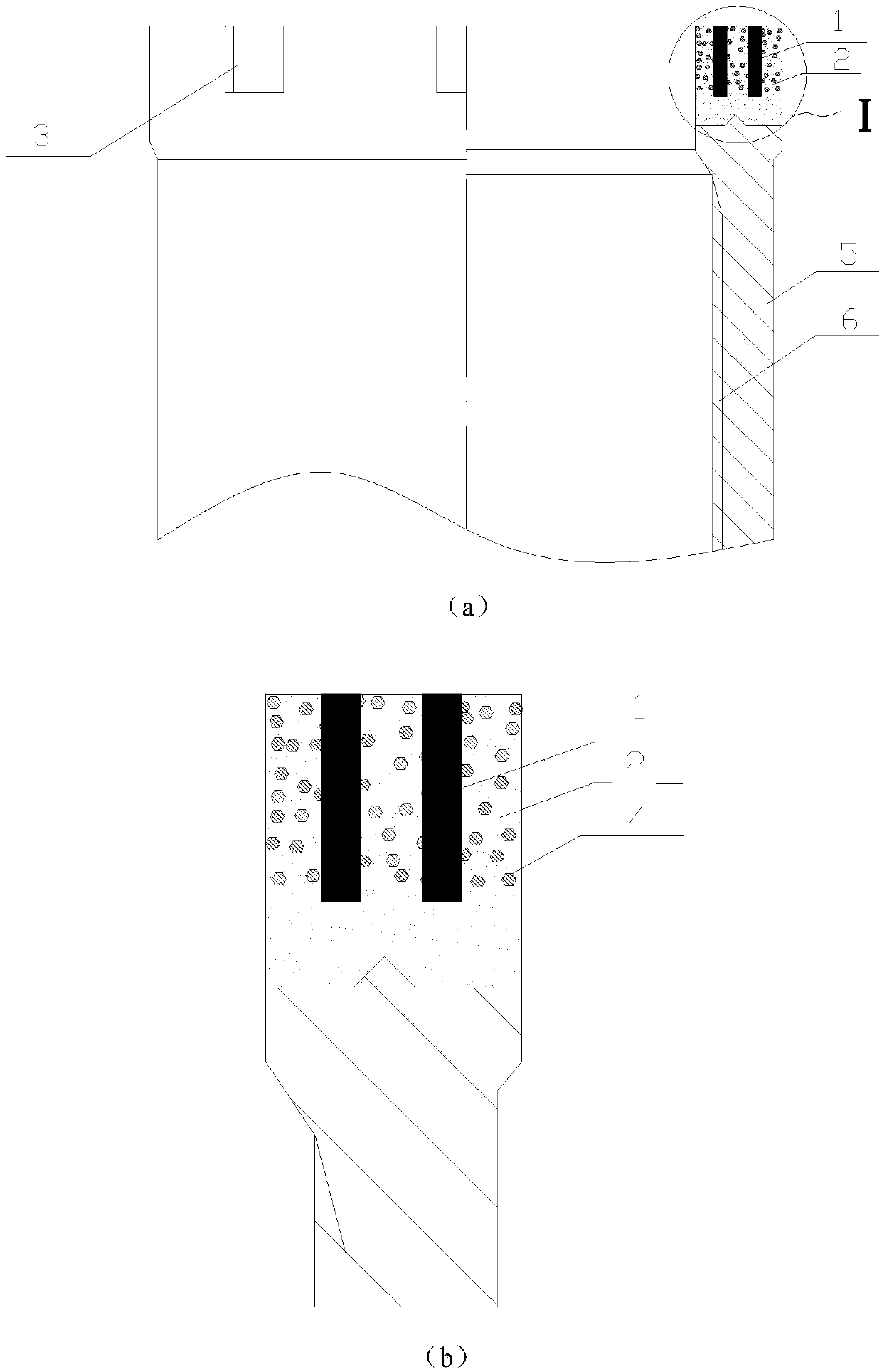

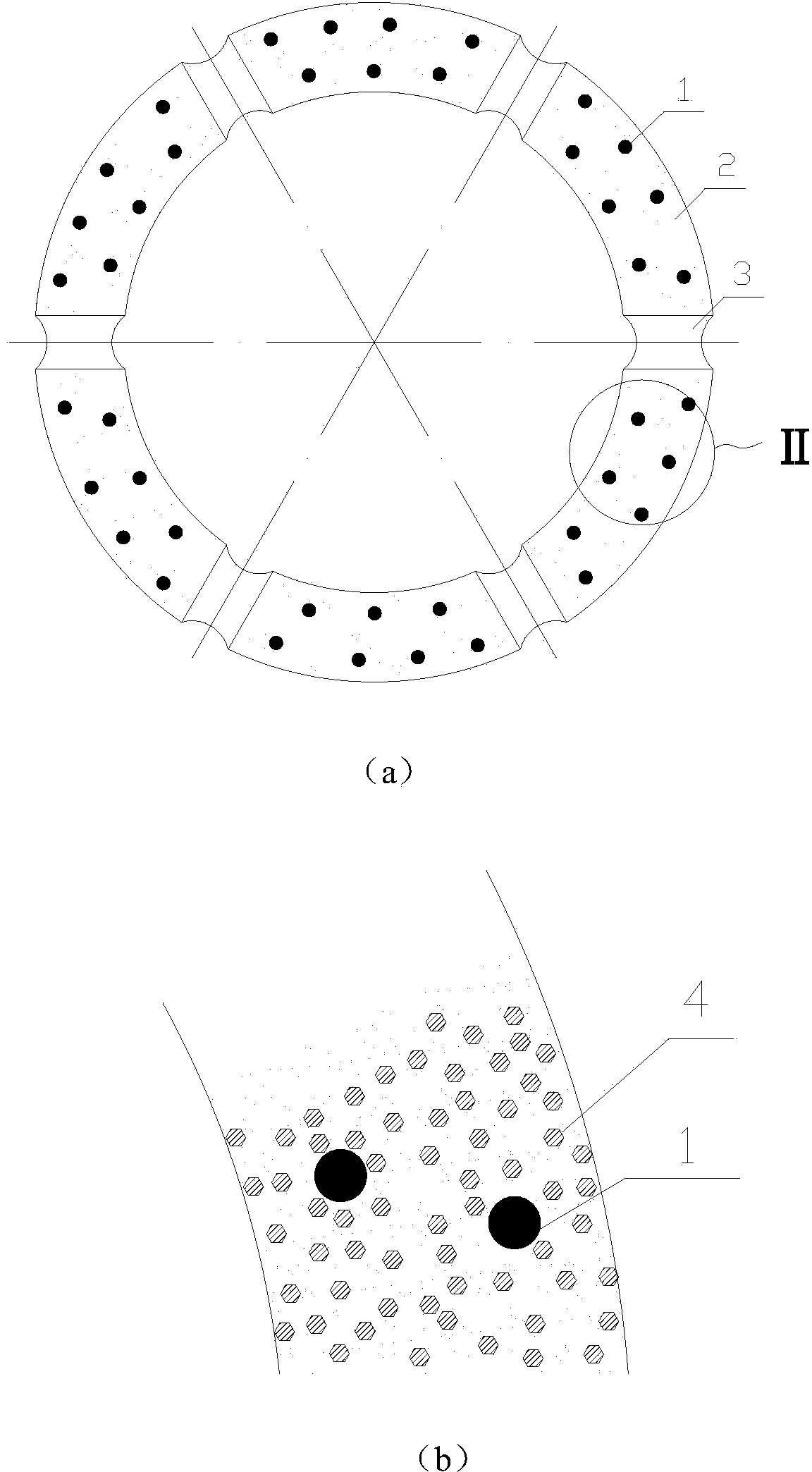

[0055] Select the drill bit size according to the actual drilling design, select the matrix formula, drill bit structure and diamond parameters according to the engineering geological lithology characteristics, and perform charging calculations, weighing, mixing, cold pressing, reduction, steel body alignment and die loading, vacuum-free Pressure sintering, heat preservation, cooling with furnace, machining, inspection and delivery.

[0056] Taking the quartz porphyry (drillability level 11) as an example for the indoor drilling test, a φ56.5 / 38mm wireline core bit is designed: nickel-based pre-alloyed powder and iron powder are used as the matrix formula, The carcass is inlaid with diamonds and thin iron wires, and the lip of the drill bit is flat-bottomed, as follows:

[0057] 1. Nickel-based carcass components (mass percentage): select 70% of nickel-chromium-boron-silicon solder produced by a certain company, 30% of iron powder, and a particle size of 200 mesh;

[0058] 2....

Embodiment 2

[0072] A field production test drill 1 of φ75.5 / 55mm was produced.

[0073] The production method of the φ75.5 / 55mm field production test drill bit 1 is basically the same as that of the indoor test drill bit, except that the diamond concentration and iron powder content are slightly different. The diamond concentration and matrix of the drill bit are designed based on the rock samples of the drilled section on site. Hardness, the diamond concentration is 80%, the iron powder content is 25%, the matrix hardness is HRC35, the diameter of the thin iron wire is 1.6mm, and the cross-sectional area of the thin iron wire accounts for 10% of the bottom lip area of the drill bit.

[0074] The test was carried out at a construction site in Jiangxi, the drilling depth was 2526.16m, and the rock stratum in the drilling section was silicified granite with drillability grade 10-11, with quartz veins in some places.

[0075] Field practice has proved that the timeliness and service life...

Embodiment 3

[0077] A field production test drill 2 of φ75.5 / 55mm was produced.

[0078] The production method of the φ75.5 / 55mm field production test drill bit 2 is basically the same as that of the indoor test drill bit, except that the diamond concentration and iron powder content are slightly different. The diamond concentration and matrix of the drill bit are designed based on the rock samples of the drilled section on site. Hardness, the diamond concentration is 60%, the iron powder content is 35%, the carcass hardness is HRC28, the diameter of the thin iron wire is 1.2mm, and the cross-sectional area of the thin iron wire accounts for 5% of the lip surface area.

[0079] The test was carried out at a construction site in Jiangxi, the drilling depth was 2612.33m, and the drilled rock was quartz porphyry with a drillability level of 11.

[0080] Field practice has proved that the timeliness and service life of brazed nickel-based diamond-impregnated drill bits produced by this techn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com