One-way spiral half soil compaction drill bit and one-way spiral half soil compaction pile construction technology

A kind of semi-squeezing and screw technology, which is applied in the direction of drill bit, earthwork drilling, sheet pile wall, etc., can solve the problems of ground uplift, cracked pile body, inability to press, drive or drill into the foundation pile, so as to improve the construction efficiency. Efficiency, the effect of reducing the amount of soil dumped, and reducing the amount of soil carried out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

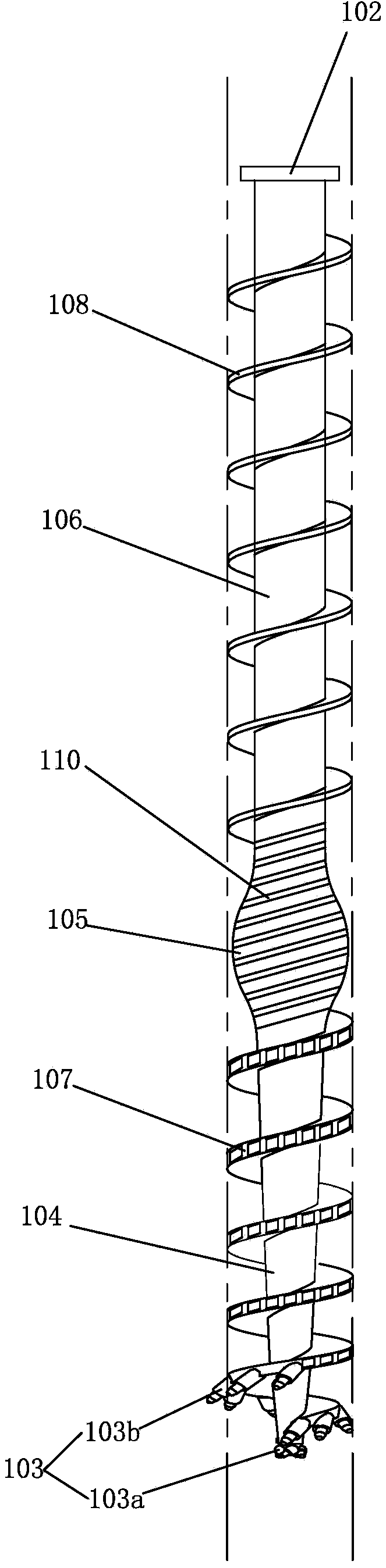

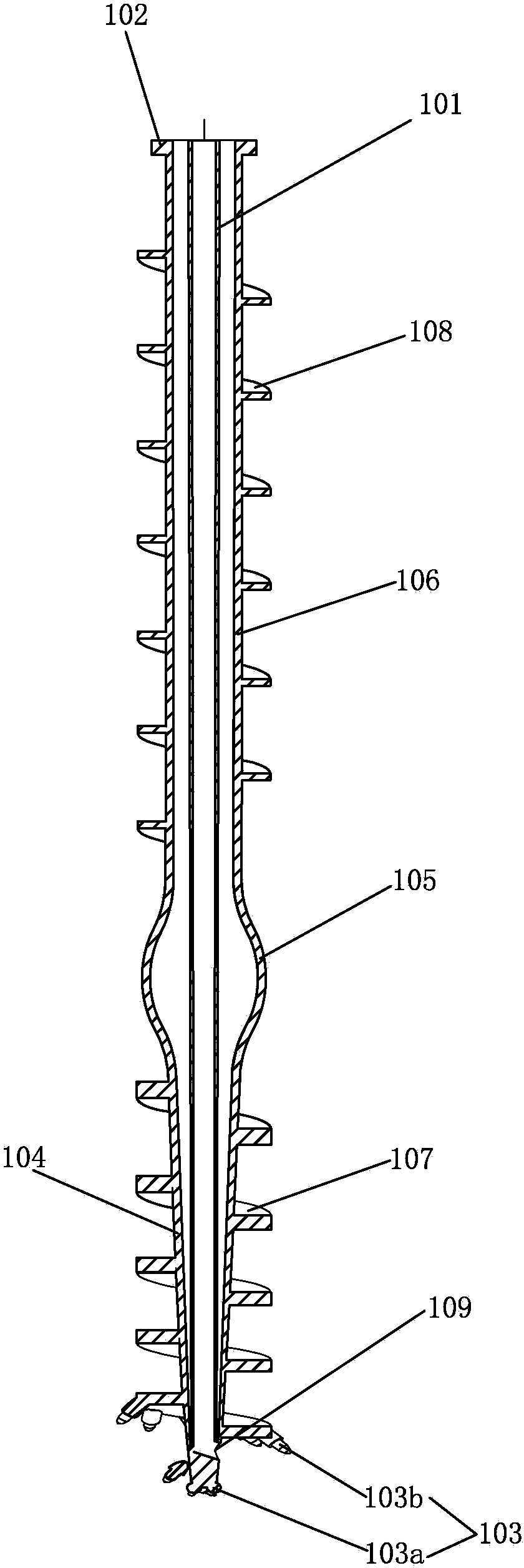

Image

Examples

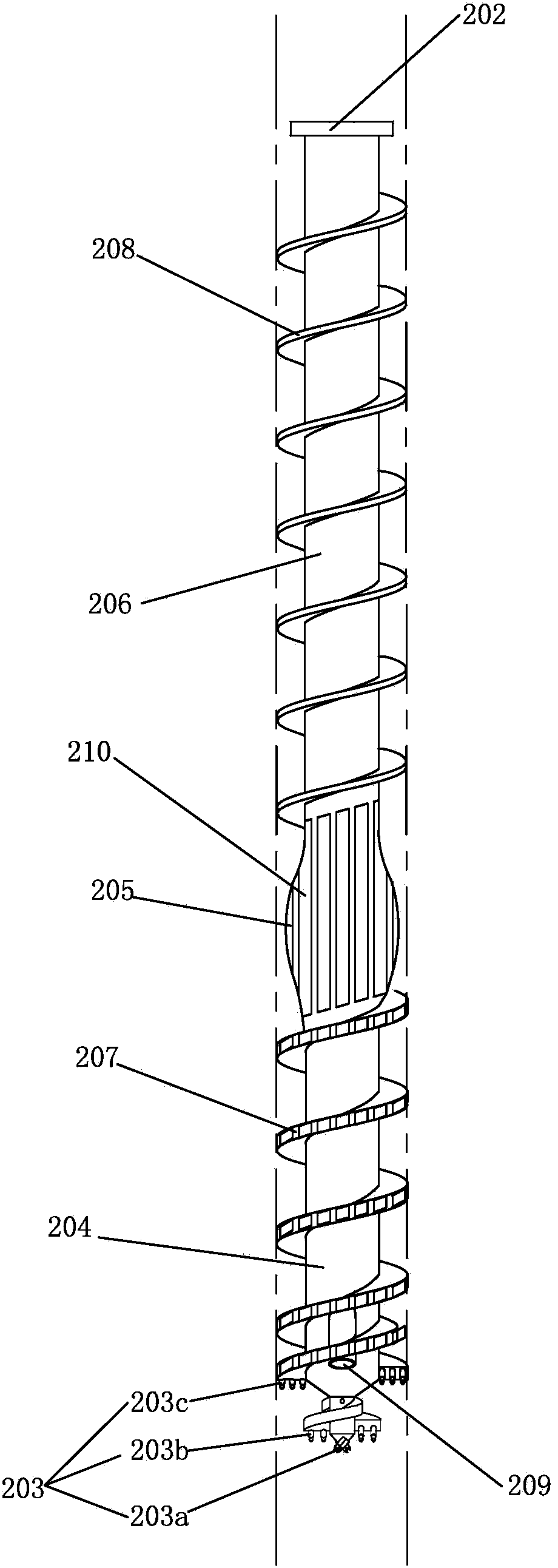

specific Embodiment approach 2

[0040] Such as image 3 , 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that: the lower spiral extruder 204 has a cylindrical shape with the same outer diameter, and the pitch S1 of the extruder blades 207 adopts an equal pitch; the non-closed extruder The outer surface of the body 205 is welded with a vertical carbide wear-resistant plate 210; the drill point 203 adopts a double-winged three-stage gradually expanding drill point, including the first stage with a carbide pick pilot drill point 203a, located in the pilot drill The second stage between the tip and the end of the lower helical extruded body has a cemented carbide bucket tooth cutting drill 203b, and the third stage installed on a circle of extruded blades closest to the drill tip has a cemented carbide bucket The tooth cutting drill 203c, the side outlet 209 is located between the second and third stage cutting drills 203b, 203c with carbide bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com