Pretreatment method for preventing cold bending cracking of austenitic stainless steel and improving corrosion resistance

An austenitic stainless steel, cold-bending and cracking technology, used in heat treatment furnaces, heat treatment equipment, ion implantation and plating, etc., can solve the problems of safety hazards of rail transit equipment, corrosion and perforation damage of stainless steel, and accelerated anode dissolution. Follow-up cleaning, elimination of internal stress, and good surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

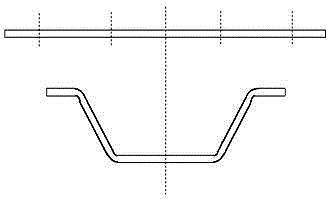

[0025] 1. The cross-section shape of 301L stainless steel plate cold-formed is as follows figure 1 As shown, calculate the horizontal distance from the bending point to the symmetry center of the stainless steel plate, and arrange the distribution position of the heating pipes according to the obtained data. Send the stainless steel plate into the designated position of the heating furnace, so that the heating tubes are distributed above the cold bending area of the stainless steel plate. Heat up the temperature to 300°C with electricity, and keep it warm for 2h.

[0026] 2. After heating and keeping warm, send the stainless steel plate to a temperature of 20°C. The composition is NaOH 60g / L, NaOH 2 SiO 3 10g / L, Na 2 CO 3 Soak in 20g / L cleaning solution 1 for 5 minutes. Then feed 65%NaOH and 20%NaNO at a temperature of 350°C 3 , 7%Na 2 SO 4 , 8%Na 2 CO 3 (wt%) in cleaning solution 2 for 15 minutes. Then the surface passes through 25% HNO at a flow rate of 10cm / s...

Embodiment 2

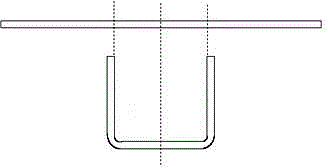

[0036] 1. The cross-section shape of 301L stainless steel plate cold-formed is as follows figure 2 As shown, calculate the horizontal distance from the bending point to the symmetry center of the stainless steel plate, and arrange the distribution position of the heating pipes according to the obtained data. Send the stainless steel plate into the designated position of the heating furnace, so that the heating tubes are distributed above the cold bending area of the stainless steel plate. Heat up the temperature to 400°C with electricity, and keep the temperature for 2.5h.

[0037] 2. After heating and keeping warm, put the stainless steel plate into the temperature 25℃, the composition is NaOH 65g / L, NaOH 2 SiO 315g / L, Na 2 CO 3 Soak in 25g / L cleaning solution 1 for 8 minutes. Then feed 70%NaOH and 25%NaNO at a temperature of 400°C 3 , 2%Na 2 SO 4 , 3%Na 2 CO 3 (wt%) in cleaning solution 2 for 20 minutes. Then the surface passes through 20% HNO at a flow rate o...

Embodiment 3

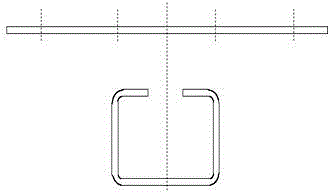

[0047] 1. The cross-section shape of 301L stainless steel plate cold-formed is as follows image 3 As shown, calculate the horizontal distance from the bending point to the symmetry center of the stainless steel plate, and arrange the distribution position of the heating pipes according to the obtained data. Send the stainless steel plate into the designated position of the heating furnace, so that the heating tubes are distributed above the cold bending area of the stainless steel plate. Heat up the temperature to 350° C. and keep it warm for 3 hours.

[0048] 2. After heating and keeping warm, send the stainless steel plate to a temperature of 30°C, the composition is NaOH 70g / L, NaOH 2 SiO 3 20g / L, Na 2 CO 3 Soak in 30g / L cleaning solution 1 for 10 minutes. Then feed 67%NaOH and 23%NaNO at a temperature of 450°C 3 , 4%Na 2 SO 4 , 6%Na 2 CO 3 (wt%) in cleaning solution 2 for 25 minutes. Then the surface passes through 15% HNO at a flow rate of 20cm / s and a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com