The preparation method of magnetic hardening fega alloy

A technology of alloy and superconducting permanent magnet, which is applied in the manufacture/assembly of magnetostrictive devices, material selection for magnetostrictive devices, device material selection, etc., which can solve the problems of high demagnetization rate, high closing and opening current, High temperature is easy to fail and other problems, to achieve low demagnetization rate, reduce opening and closing current, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

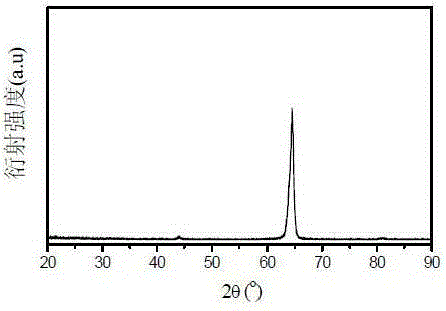

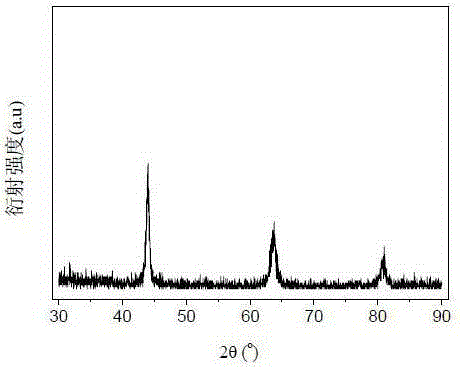

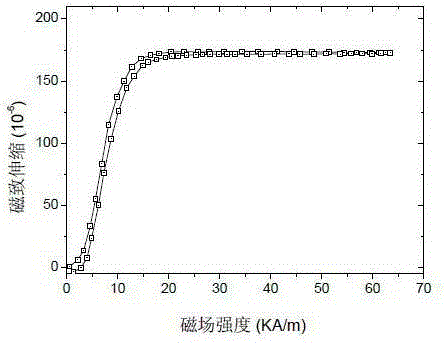

Image

Examples

preparation example Construction

[0037]Under the prior art, different heat treatment methods for iron-based alloys can form different types of magnetic hardening alloys such as quenched steel type, α / γ phase transformation type, metastable phase decomposition type and precipitation type. The inventors of the present invention have found that micro-alloying and directional casting to prepare oriented FeGa alloys, and finally magnetizing with superconducting strong magnets is another new way of magnetic hardening of FeGa alloys. Directional casting can obtain unidirectionally grown crystals whose growth direction is consistent with the principal stress direction, eliminate transverse grain boundaries, improve the unidirectional mechanical strength of the alloy, and more importantly, lay a solid foundation for subsequent magnetization and magnetic retention. Base. Concrete preparation method comprises the following steps:

[0038] (1) Smelting and casting: First weigh Ga, C, Mn and Fe and other raw materials an...

Embodiment 1

[0043] Weigh Fe, Ga, Mn, C and other raw materials with a purity greater than 99.9% with an electronic balance, and put them in In the water-cooled copper crucible in the vacuum induction furnace, adjust the vacuum degree of the vacuum chamber to 4×10 -3 Pa, introduce high-purity argon as a protective gas, adjust the heating power to completely melt the raw materials, then rapidly solidify them into alloy ingots in a water-cooled copper crucible, and then turn over the alloy ingots for melting. The composition is uniform, and then cast into a mold with a water-cooled copper bottom for directional casting into a FeGa alloy billet.

[0044] Put the FeGa alloy billet into the vacuum heat treatment furnace, and adjust the vacuum degree of the vacuum chamber to (2~4)×10 -3 Pa, and then pass inert gas such as argon as protective gas, the pressure is 5×10 4 Pa, in a protective gas atmosphere, the temperature is raised to 1100°C at a rate of 80°C / hour for 8 hours, and then cooled to...

Embodiment 2

[0049] First, weigh Fe, Ga, Mn, C and other raw materials with a purity greater than 99.9% with an electronic balance, according to the mass percentage Ga: 10.00wt%, C: 0.45wt%, Mn: 0.72wt%, and the balance of Fe after weighing. into the water-cooled copper crucible in the vacuum induction furnace, and adjust the vacuum degree of the vacuum chamber to 3×10 -3 Pa, and then pass inert gas such as high-purity argon as a protective gas, adjust the heating power to completely melt the raw material, then make it quickly solidify into an alloy ingot in a water-cooled copper crucible, and then turn over the alloy ingot for melting, so repeatedly smelting for 4 Make the composition of the alloy uniform for the first time, and then cast it into a mold with a water-cooled copper bottom to form a FeGa alloy billet.

[0050] Put the FeGa alloy billet into the vacuum heat treatment furnace, and adjust the vacuum degree of the vacuum chamber to (2~4)×10 -3 Pa, and then pass inert gas such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com