A bonded magnet and its preparation method

A technology of bonded magnets and magnetic powders, applied in the field of magnetic therapy, can solve the problems of low bonding strength of magnetic powders and base materials, inability to achieve single-sided unipolarity, resistance to contact, low resistance to strong bending, etc., and achieves easy promotion and is not easy to fall off or loss, the effect of low demagnetization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

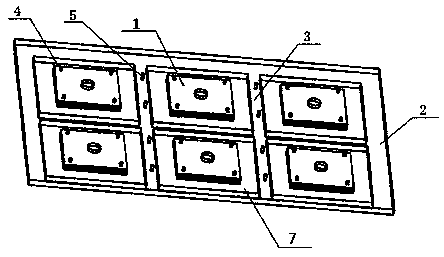

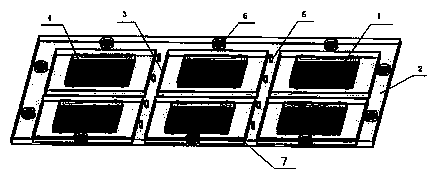

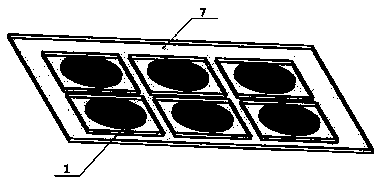

Image

Examples

Embodiment 1

[0078] A bonded magnet, the mass ratio of the components of the bonded magnet is as follows: 30 parts of magnetic powder, 3 parts of chlorinated polyethylene, and 0.3 parts of epoxy soybean oil.

[0079] A method for preparing a bonded magnet, comprising the steps of:

[0080] (1) Take each component according to the ratio of mass and number, and use a banbury mixer for banbury mixing, with a pressure of 0.8Mpa, a rotor speed of 75r / min, and a temperature of 140°C. First, put chlorinated polyethylene into the banbury chamber, and After refining for 2 minutes, add epoxidized soybean oil, banbury for 3 minutes, finally add magnetic powder, continue banburying for 2 minutes, lower the temperature to 100°C, banbury for 4 minutes, then raise the temperature to 120°C, banbury for 18 minutes, and release material;

[0081] (2), put the material mixed in the step (1) into a calender for 2 times, and the calendering temperature is 70°C to obtain a magnetic plate with a thickness of 1....

Embodiment 2

[0086] A bonded magnet, the mass ratio of each component of the bonded magnet is as follows: 45 parts of magnetic powder, 3 parts of chlorinated polyethylene, and 0.3 part of epoxy soybean oil.

[0087] A method for preparing a bonded magnet, comprising the steps of:

[0088] (1) Take each component according to the ratio of mass and number, and use a banbury mixer for banbury mixing, with a pressure of 0.8Mpa, a rotor speed of 75r / min, and a temperature of 140°C. First, put chlorinated polyethylene into the banbury chamber, and After refining for 2 minutes, add epoxidized soybean oil, banbury for 3 minutes, finally add magnetic powder, continue banburying for 2 minutes, lower the temperature to 100°C, banbury for 4 minutes, then raise the temperature to 120°C, banbury for 18 minutes, and release material;

[0089] (2), put the material mixed in the step (1) into a calender for 2 times, and the calendering temperature is 70°C to obtain a magnetic plate with a thickness of 1.2...

Embodiment 3

[0094] A bonded magnet, the mass ratio of the components of the bonded magnet is as follows: 78 parts of magnetic powder, 3 parts of chlorinated polyethylene, and 0.3 part of epoxy soybean oil.

[0095] A method for preparing a bonded magnet, comprising the steps of:

[0096] (1) Take each component according to the ratio of mass and number, and use a banbury mixer for banbury mixing, with a pressure of 0.8Mpa, a rotor speed of 75r / min, and a temperature of 140°C. First, put chlorinated polyethylene into the banbury chamber, and After refining for 2 minutes, add epoxidized soybean oil, banbury for 3 minutes, finally add magnetic powder, continue banburying for 2 minutes, lower the temperature to 100°C, banbury for 4 minutes, then raise the temperature to 120°C, banbury for 18 minutes, and release material;

[0097] (2) Put the material mixed in step (1) into a calender for 2 times, and the calendering temperature is 70°C. During the calendering, the magnetic plate is seriousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com