Compact pure-phase lanthanum zirconate ceramic with low thermal conductivity and high strength, and preparation method thereof

A technology of phase lanthanum zirconate and low thermal conductivity, which is applied in the field of high-strength dense pure phase lanthanum zirconate ceramics and its preparation, and low thermal conductivity. It can solve the problem that thermal conductivity and mechanical strength are difficult to meet actual needs, low thermal conductivity, etc. problems, to meet the requirements of heat insulation performance and mechanical bearing performance, long service life, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

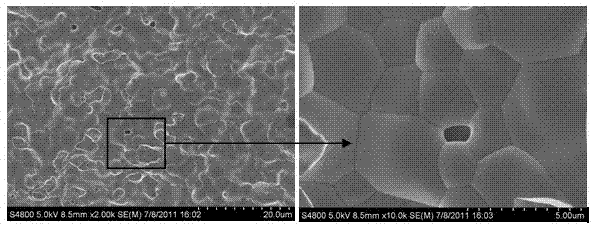

[0027] Such as figure 1 As shown, the steps of the preparation method of low thermal conductivity, high-strength dense pure-phase lanthanum zirconate ceramics are as follows:

[0028] 1) Mix the aqueous solutions of lanthanum nitrate and zirconium oxychloride with a concentration of 0.1~1mol / L and stir for 0.5~1h to form La 3+ with Zr4+ For the mixed solution with a molar ratio of 1:1, add the mixed solution dropwise to ammonia water at a rate of 10~60ml / min, continue to stir for 0.5~2h after the dropwise addition, and then let it stand for 12~24h. After standing, the supernatant When the pH value of the solution reaches 10~13, the precipitate is washed and separated with deionized water. When the pH value of the supernatant is 7, it is washed and separated with ethanol, and dried at 80~110°C for 12~24h to obtain an amorphous powder ;

[0029] 2) Ball mill the amorphous powder for 1~3h, heat-treat at 400~1100°C for 3~6h, ball mill for 3~8h, and sieve to obtain submicron powd...

Embodiment 1

[0033] 1) Mix the aqueous solutions of lanthanum nitrate and zirconium oxychloride with a concentration of 0.1mol / L and stir for 1 hour to form La 3+ with Zr 4+ For a mixed solution with a molar ratio of 1:1, add the mixed solution dropwise to the ammonia precipitation agent at a rate of 10ml / min, continue stirring for 2 hours after the dropwise addition, and then leave it to age for 24 hours. After standing, the pH value of the supernatant reaches 10~13, wash and separate with deionized water, when the pH value of the supernatant is 7, wash and separate with ethanol, and dry at 80°C for 24 hours to obtain an amorphous powder;

[0034] 2) Ball mill the amorphous powder for 3 hours, heat treatment at 700°C for 5 hours, ball mill for 8 hours, and sieve to obtain submicron powder with an average particle size of 300nm, add 8% polyvinyl alcohol solution of submicron powder mass to granulate , the mass percentage of polyvinyl alcohol in the polyvinyl alcohol solution is 5%, and it...

Embodiment 2

[0039] 1) Mix aqueous solutions of lanthanum nitrate and zirconium oxychloride with a concentration of 0.3 mol / L and stir for 1 hour to form La 3+ with Zr 4+ For a mixed solution with a molar ratio of 1:1, add the mixed solution dropwise to the ammonia water precipitant at a rate of 20ml / min, continue to stir for 1.5h after the dropwise addition, and then leave it to age for 20h. After standing, the pH value of the supernatant is reach 10~13, wash and separate with deionized water, when the pH value of the supernatant is 7, wash and separate with ethanol, and dry at 100°C for 12 hours to obtain an amorphous powder;

[0040] 2) The amorphous powder was ball milled for 2.5 hours, heat treated at 900°C for 4 hours, ball milled for 6 hours, and sieved to obtain a submicron powder with an average particle size of 400nm. Add 7% polyvinyl alcohol solution of submicron powder mass to make Granules, dried at 90°C until the amount of polyvinyl alcohol solution accounted for 2.5% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com