Power tube drive method and circuit, and direct-current solid power controller

A solid-state power and drive circuit technology, applied in electrical components, electronic switches, pulse technology, etc., can solve the problems of unstable switching speed, complex implementation of technical solutions, and large impact, and achieve easy integration, simple and reliable drive circuits. , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe the present invention in detail below in conjunction with accompanying drawing.

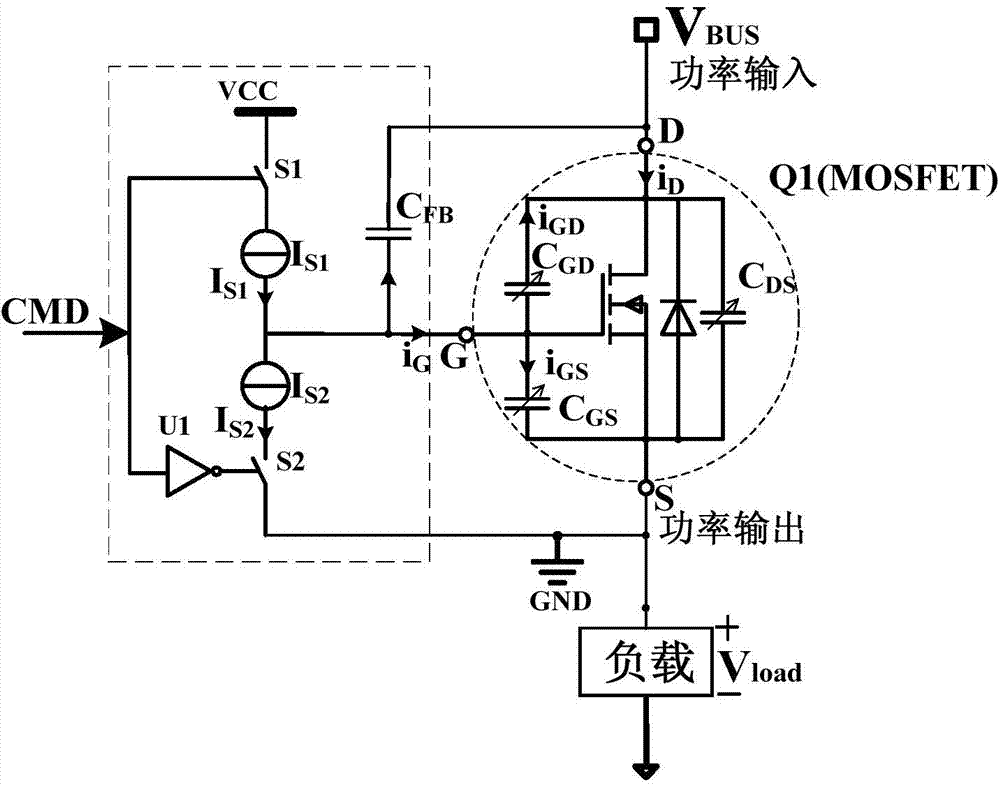

[0022] Such as figure 1 Shown in the rectangular dotted line frame is the DC solid-state power controller power tube drive circuit proposed by the present invention, including the first switch S1, the first constant current source I S1 , the second switch S2, the second constant current source I S2 , NOT gate U1 and feedback capacitor C FB . The first switch S1 and the first constant current source I S1 The first channel is formed in series, the second switch S2 and the second constant current source I S2 Connected in series to form the second channel. The first channel and the second channel are connected in series between the positive pole VCC of the power supply of the driving circuit and the reference ground GND, the connection point of the first channel and the second channel is connected to the gate of the power transistor Q1, and the reference ground GND of the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com