Lithium thionyl chloride battery electrolyte and its making method

A technology of lithium thionyl chloride battery and thionyl chloride solution, which is applied to secondary batteries, secondary battery parts, non-aqueous electrolyte batteries, etc., and can solve problems such as potential safety hazards, explosion and leakage of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

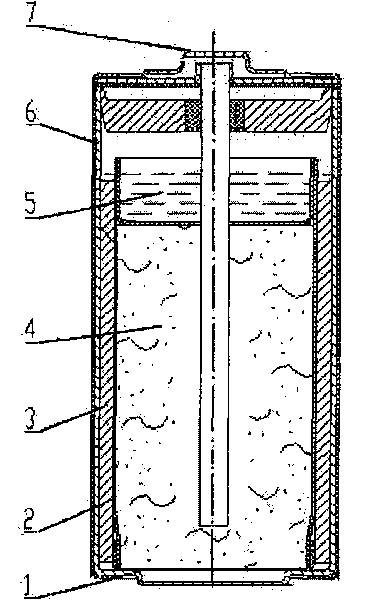

Image

Examples

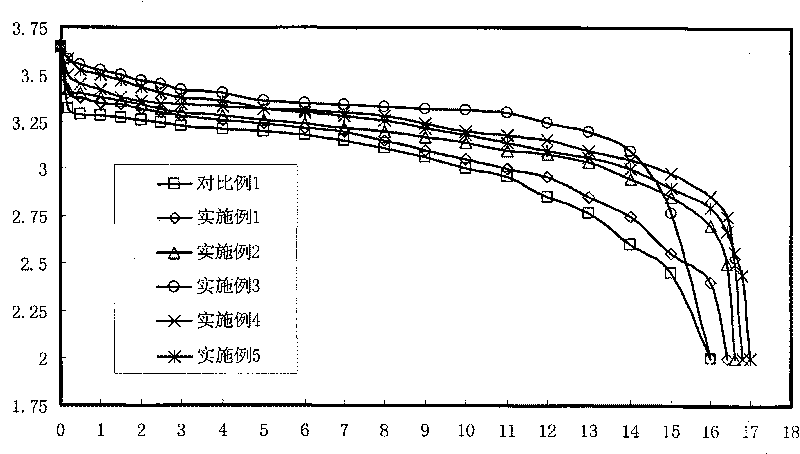

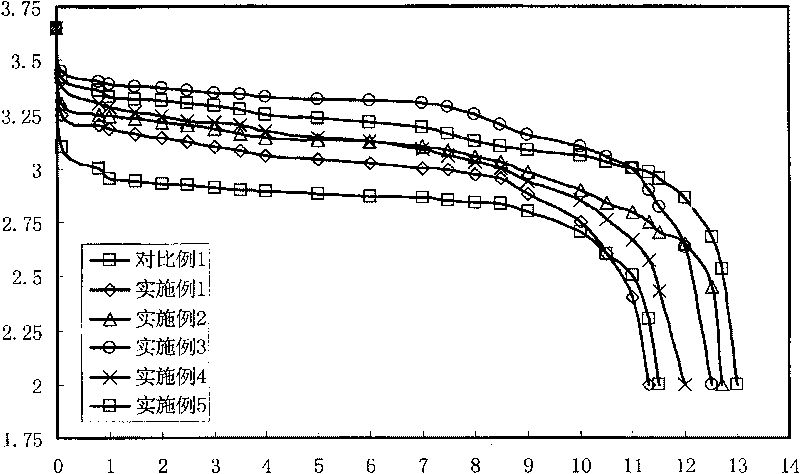

Embodiment 1

[0038] The electrolytic solution is a 0.8 mol / L lithium tetrachloroaluminate solution in thionyl chloride, to which 0.8% (mass ratio) of triphenyl phosphate is added.

Embodiment 2

[0040] The electrolyte is a 0.8 mol / L lithium tetrachloroaluminate solution in thionyl chloride, to which 3% (mass ratio) of triphenyl phosphate is added.

Embodiment 3

[0042] The electrolytic solution is a 0.8 mol / L lithium tetrachloroaluminate solution in thionyl chloride, to which 7.5% (mass ratio) of triphenyl phosphate is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com