A high-efficiency electromagnetic synchronous synergistic coalescence device

A coalescing device and synergistic technology, which can be used in electrical/magnetic dehydration/demulsification, treatment of hydrocarbon oil, petroleum industry, etc. It is difficult to improve and other problems to achieve the effect of improving oil-water separation efficiency, enhancing allowable electric field strength, and reducing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

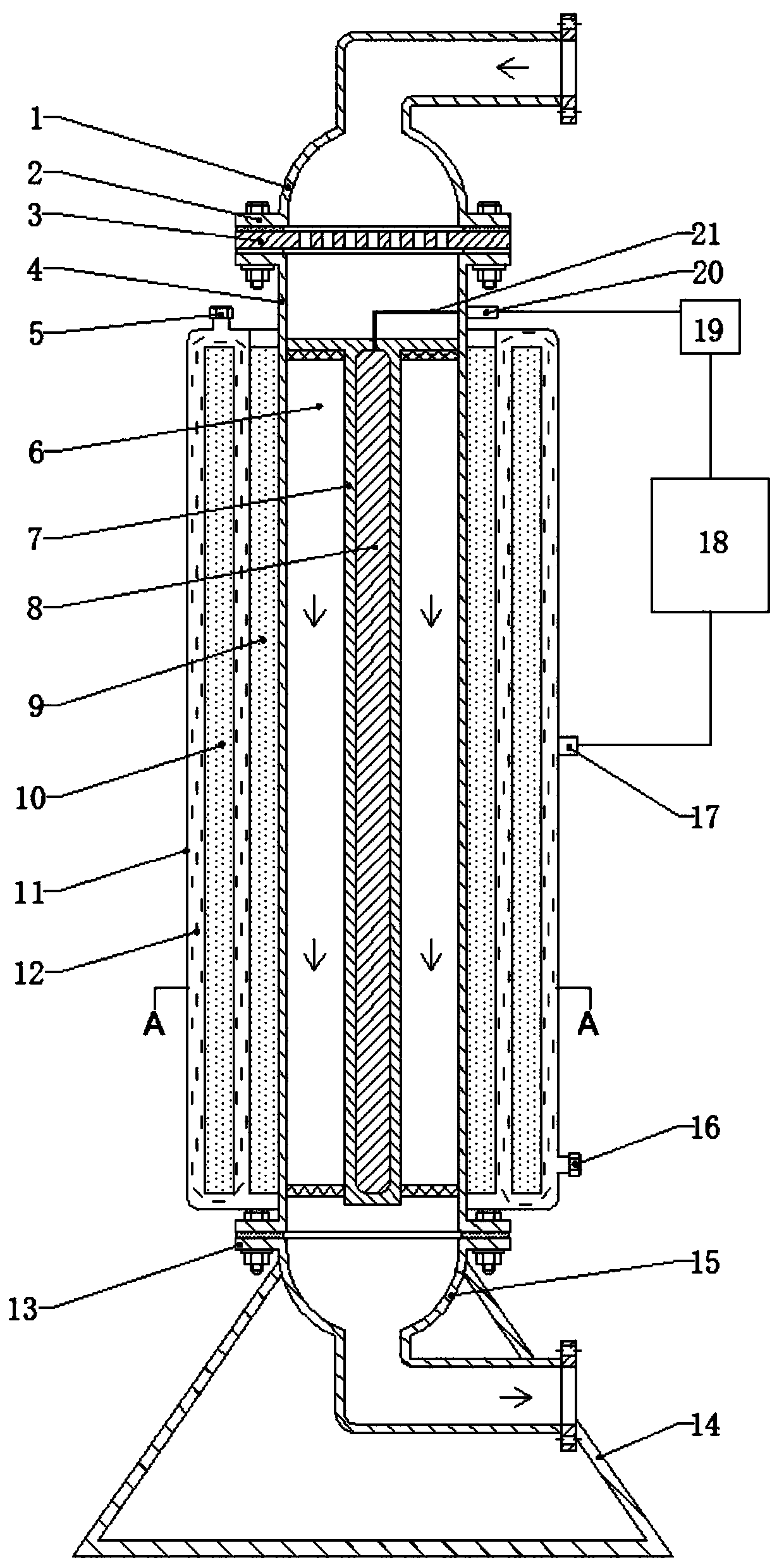

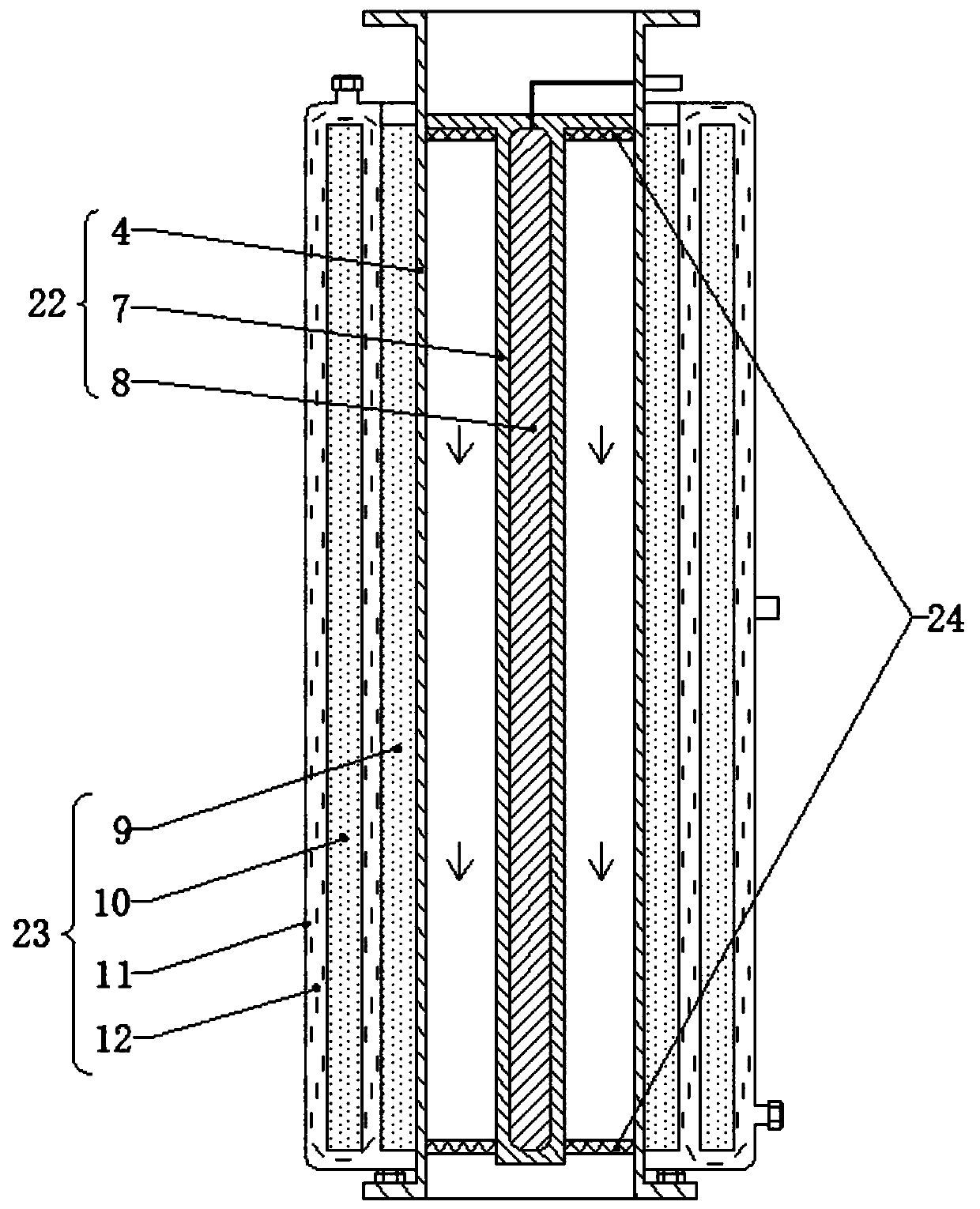

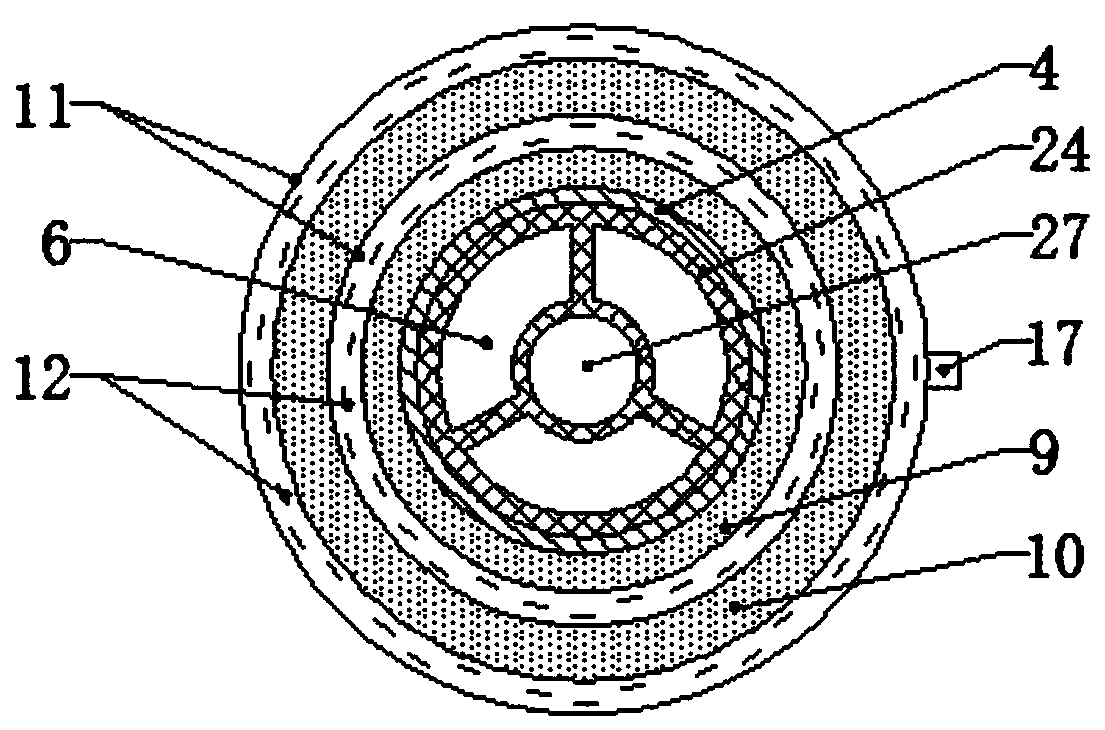

[0039] Such as figure 1 with figure 2 , the present invention comprises that the emulsion enters the inlet head 1 with the inlet head flange 2 at the upper end, and the outlet head 15 with the outlet head flange 13 at the lower end, and a polymer that contains an electromagnetic synchronous coordination device between the two. The junction body, the base 14, the transformer 19 and the power distribution cabinet 18 are characterized in that the above-mentioned inlet head 1 and the outlet head 15 contain an electromagnetic synchronous coordination device, and the inlet head 1 and the cylindrical outer electrode 4 is provided with a liquid distribution orifice 3, and the electromagnetic synchronous coordination device includes an electric field generating component 22 and a magnetic field excitation component 23, both of which are coaxially distributed, and the electric field is horizontally distributed from the electrode 8 to the electrically grounded cylindrical outer electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com