Curie-point pyrolyser of volatile matter generated by element in element determination

A technology of element determination and Curie point, which is applied in the field of instrument analysis, can solve the problems of slow heating rate of tube furnace cracker, peak and tailing of element volatiles, and prolonged measurement time, so as to improve the cracking rate of samples by heating up, The peak shape is sharp and the peak is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

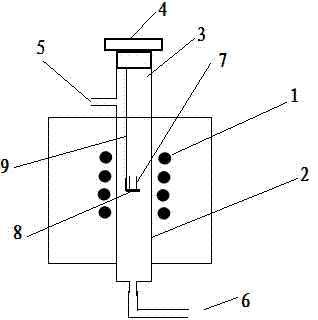

[0043] A Curie point pyrolyzer used for generating volatiles from elements during element determination, comprising an induction heating coil 1, a quartz reaction liner 2, a reaction chamber 3, a reaction tube sealing plug and a sample holder integration device 4, and a carrier gas inlet 5 , carrier gas outlet 6, sample crucible 7 (preferably 500°C-800°C), sample crucible support 8, crucible support 9, wherein crucible or foil support support and sealing plug connecting rod; The time required for the inside point material to rise from room temperature to the Curie point temperature after heating is less than 500 milliseconds. The element samples to be measured are directly loaded in the Curie point pyrolysis crucible. When the sample of the element to be measured is indirectly loaded in the Curie point crucible, a layer of high molecular polymer is sprayed on the surface of the crucible sample; the thickness of the crucible wall is 0.08-1 mm. Among them, the high molecula...

Embodiment 2

[0046] A Curie point pyrolyzer used for generating volatiles from elements during element determination, comprising an induction heating coil 1, a quartz reaction liner 2, a reaction chamber 3, a reaction tube sealing plug and a sample holder integration device 4, and a carrier gas inlet 5 , a carrier gas outlet 6, a foil 7, a holder 8 for carrying the sample foil, and a holder 9 for carrying the foil.

[0047] The sample crucible or foil of the present invention is composed of a Curie point material with a Curie point temperature of 980° C., and the time required for the sample to rise from room temperature to the Curie point temperature after being heated by the Curie point material is less than 300 milliseconds.

[0048] The Curie point pyrolyzer used to generate volatiles from elements during element determination according to the present invention, wherein the sample of the element to be measured is directly or indirectly loaded in the Curie point pyrolytically wrapped and...

Embodiment 3

[0051] Analysis of Arsenic Content in Rice

[0052]Use the device described in preferred embodiment one to carry out the determination of arsenic content in rice flour. Accurately weigh 4 mg of rice flour sample into an iron crucible, then put the crucible into a quartz tube, turn on the high-frequency coil power supply for induction heating, at this time the Curie point temperature of the iron crucible is 770°C. The elemental volatiles and organics produced by the pyrolysis are carried by the carrier gas (argon, 300 ml / min) and passed through a three-stage semi-conductor refrigeration condenser device (condensation temperature -20°C) and a quartz wool filter layer. After purification, the rice flour The volatile matter of arsenic in the element is detected by atomic fluorescence (the atomic fluorescence atomizer is connected with a hydrogen generator with a hydrogen generation rate of 450 ml / min, so as to provide a hydrogen source for the normal ignition of the atomizer). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com