Polyacrylamide as well as preparation method and application thereof

A technology of polyacrylamide and polymerization reaction, which is applied in the field of polyacrylamide and its preparation, can solve problems such as prone to detonation, high energy consumption, and harsh reaction conditions, and achieve the goal of reducing energy consumption, simplifying process conditions, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

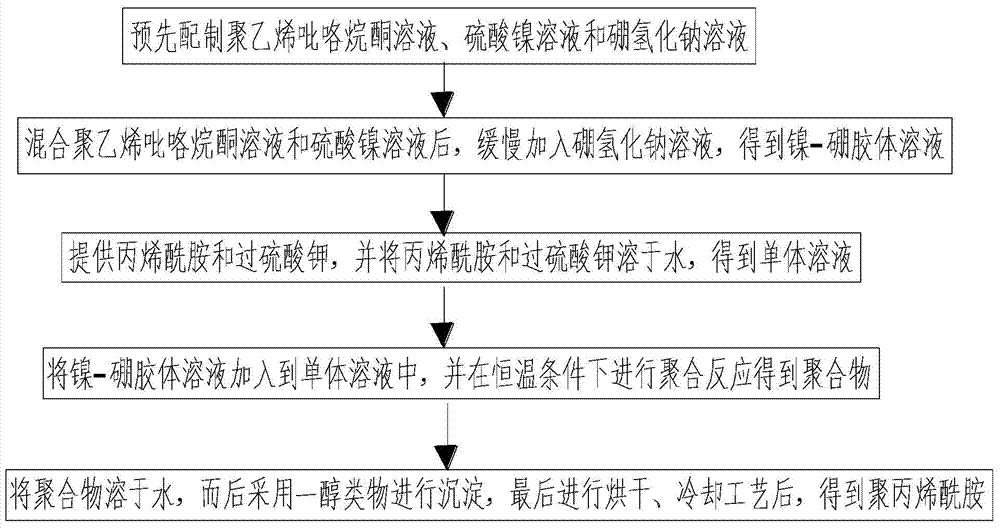

[0032] figure 1 It is a schematic flow diagram of the preparation method of polyacrylamide provided by Example 1 of the present invention; as figure 1 As shown in the flow chart, the preparation method of polyacrylamide provided by Example 1 of the present invention includes: placing a certain amount of polyvinylpyrrolidone in a beaker, and then adding distilled water to dissolve to obtain a polyvinylpyrrolidone solution; adding a certain amount of NiSO 4 ·7H 2 O is placed in a beaker, and then distilled water is added to dissolve to obtain a nickel sulfate solution; a certain amount of sodium borohydride is placed in a beaker, and then distilled water is added to dissolve to obtain a sodium borohydride solution;

[0033] After fully mixing the polyvinylpyrrolidone solution and the nickel sulfate solution, slowly add the sodium borohydride solution under stirring conditions, the reaction is complete, and the nickel-boron colloidal solution can be obtained;

[0034] Provide a...

Embodiment 2

[0038] Weigh 2.5g of polyvinylpyrrolidone (PVP) and place it in a beaker, add 20mL of distilled water to dissolve it, and prepare a polyvinylpyrrolidone solution; weigh 0.59g of NiSO 4 ·7H 2O is placed in a beaker, and then 20mL of distilled water is added to dissolve to prepare a nickel sulfate solution; 0.172g of sodium borohydride is weighed and placed in a beaker, and then 20mL of distilled water is added to dissolve to prepare a sodium borohydride solution; the polyvinylpyrrolidone solution Fully mix with nickel sulfate solution, then slowly add sodium borohydride solution while stirring, after the reaction is complete, nickel-boron colloidal solution can be obtained; meanwhile, take 7.82g of acrylamide and 0.15g of potassium persulfate, and Dissolve acrylamide and potassium persulfate in 20mL of water to obtain a monomer solution; add nickel-boron colloid solution to the monomer solution, add 80mL of water, and carry out polymerization reaction under the condition of a c...

Embodiment 3

[0041] Weigh 2.5g of polyvinylpyrrolidone (PVP) and place it in a beaker, add 20mL of distilled water to dissolve it, and prepare a polyvinylpyrrolidone solution; weigh 0.59g of NiSO 4 ·7H 2 O is placed in a beaker, and then 20mL of distilled water is added to dissolve to prepare a nickel sulfate solution; 0.0172g of sodium borohydride is weighed and placed in a beaker, and then 20mL of distilled water is added to dissolve to prepare a sodium borohydride solution; the polyvinylpyrrolidone solution Fully mix with nickel sulfate solution, then slowly add sodium borohydride solution while stirring, after the reaction is complete, nickel-boron colloidal solution can be obtained; meanwhile, take 7.82g of acrylamide and 0.15g of potassium persulfate, and Dissolve acrylamide and potassium persulfate in 20mL of water to obtain a monomer solution; add nickel-boron colloid solution to the monomer solution, add 80mL of water, and carry out polymerization reaction under the condition of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com