Process for treating landfill leachate

A technology for landfill leachate and treatment process, which is applied in the field of biofilm denitrification and decarbonization combined treatment of landfill leachate, which can solve the problem of increasing land area and investment funds, sludge cultivation being susceptible to external interference, and complex operation and management. and other problems, to achieve the effect of shortening the residence time, easy maintenance and repair, and improving the efficiency of denitrification treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment one, the leachate of a certain waste-to-energy plant is selected for treatment. The garbage leachate treatment station of the waste-to-energy plant is used as supporting facilities to treat the garbage leachate in the garbage storage pit, with a processing capacity of 150m 3 / d.

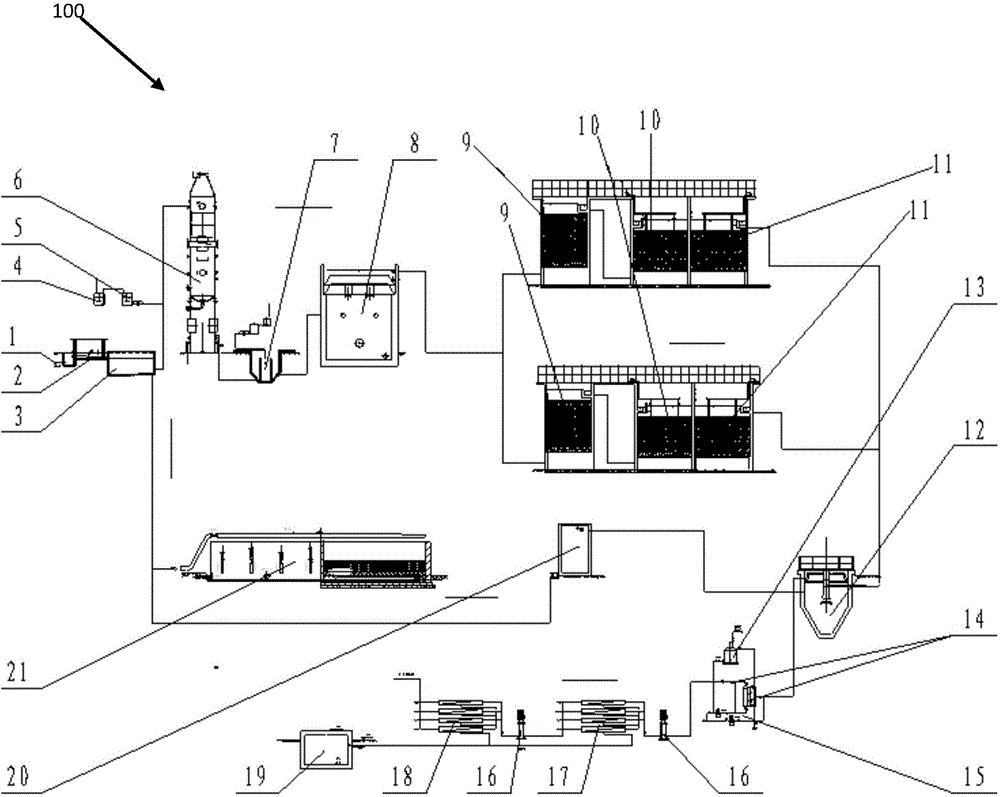

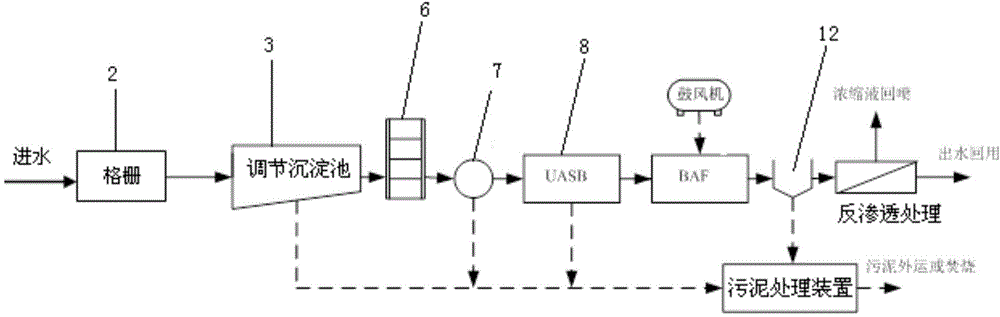

[0032] figure 1 It is a structural schematic diagram of the landfill leachate treatment system involved in the present invention in Embodiment 1.

[0033] Such as figure 1 As shown, the landfill leachate treatment station 100 is provided with:

[0034] Pretreatment device: including garbage leachate tank 1, grid 2 and regulating sedimentation tank 3 connected in sequence, garbage leachate tank 1 is used to store garbage leachate, grid 2 is used to remove large suspended matter, Adjust the specification of the sedimentation tank 3 to 12m×8m×4m, which is used to remove small suspended solids;

[0035] The ammonia removal device includes the alkali storage tank 4, the alka...

Embodiment 2

[0069] In this embodiment two, the garbage fermentation liquid of a certain garbage incineration power plant is selected for processing, and the processing capacity is 200m 3 / d. Influent COD of the garbage fermentation broth Cr The concentration is 50000mg / L, NH 3 - The concentration of N is 3000mg / L, the concentration of SS is 4000mg / L, and the pH is between 6.0 and 9.0. The water quality of the garbage fermentation liquid is unstable.

[0070] In Example 2, the waste fermentation broth is pretreated by using grilles and coagulation sedimentation tanks. Coagulation sedimentation not only effectively reduces the content of suspended solids in the fermentation broth, but also reduces COD. In the obtained pretreatment solution, COD Cr The removal rate was 75%.

[0071] After deammonization treatment in the ammonia distillation tower, the removal rate of ammonia nitrogen in the obtained primary treatment liquid reaches 95%.

[0072] Biodegradation is treated with anaerobic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com