Electro-hydraulic composite braking system hierarchical control structure and method of integrated braking cylinder

An electro-hydraulic composite, brake master cylinder technology, applied in the direction of brake transmission, brake, transportation and packaging, can solve the problems such as the inability to apply the structure of the integrated master cylinder electro-hydraulic composite brake system, and achieve scalability and reliability. Good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

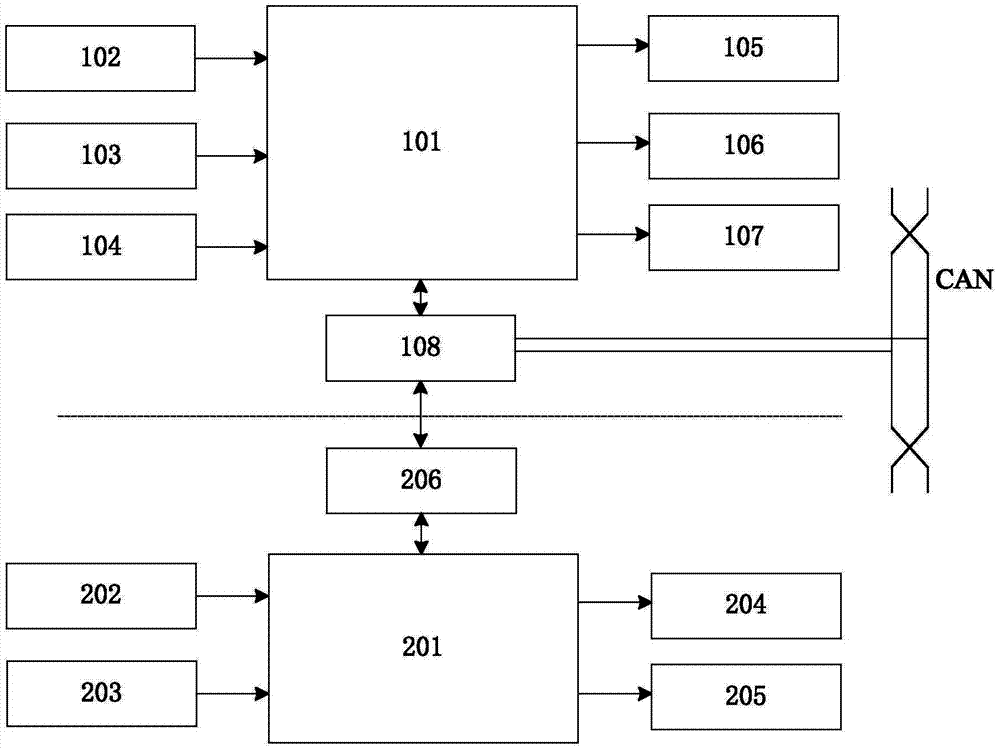

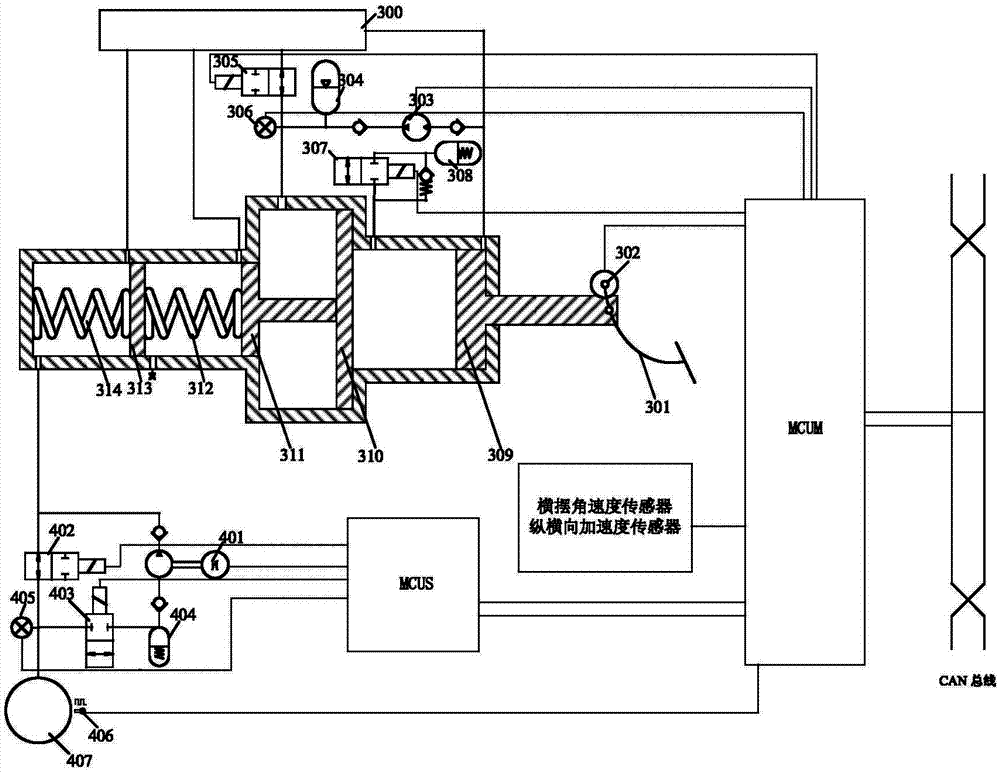

[0051] The hierarchical control architecture of the electro-hydraulic composite brake system suitable for the integrated brake master cylinder, its structure is as follows: figure 1 As shown, it includes the upper electro-hydraulic compound brake control unit and the lower hydraulic control unit.

[0052] The upper electro-hydraulic brake control unit consists of an analog processing circuit 102, a digital processing circuit 103, a power supply module 104, a microprocessor 101, a pump driving circuit 105, a valve driving circuit 106, a status indicator 107 and a communication module 108. The analog quantity processing circuit 102, the digital quantity processing circuit 103, the power supply module 104 input signals to the microprocessor 101, and the microprocessor 101 supplies the pump driving circuit 105, the valve driving circuit 106, the state indication 107, the communication module 108 and the microprocessor 101 Connect and exchange information with the lower hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com