Production technology for 345MPa-level hot-rolled plate roll

A hot-rolled coil and production process technology, applied in the direction of temperature control, can solve problems such as large fluctuation, low elongation, quality objection, etc., and achieve the effect of reducing sulfide inclusions, improving metallographic structure, and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

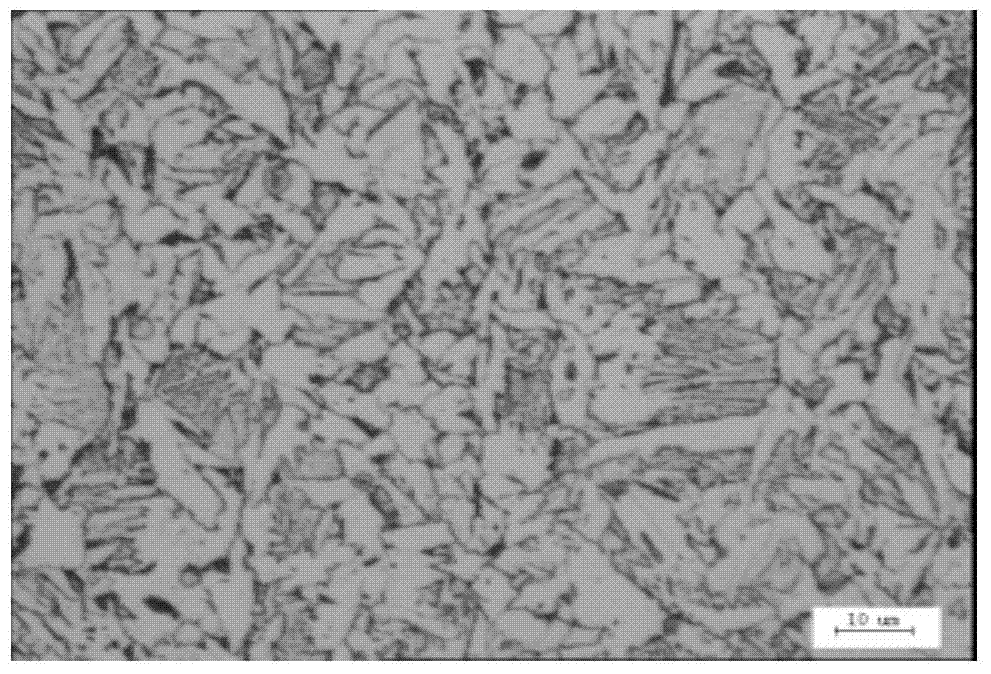

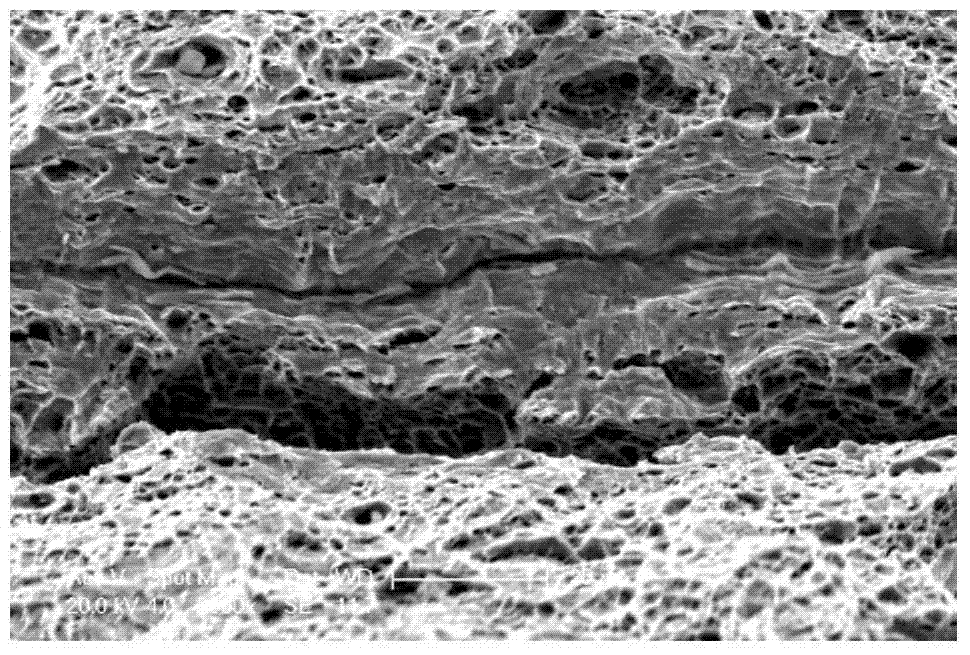

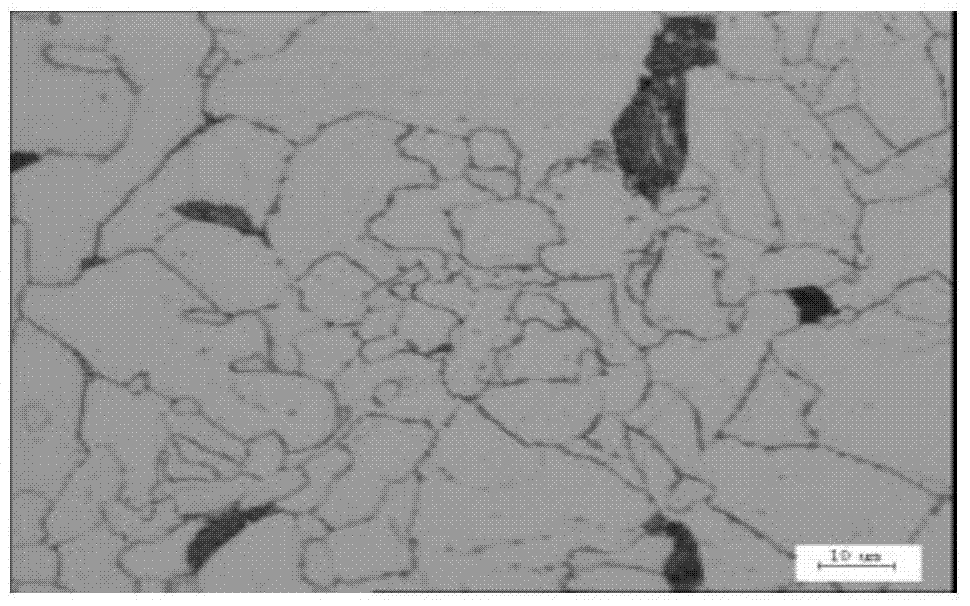

Image

Examples

Embodiment approach 1

[0038] 345MPa grade hot-rolled coil composition ratio by weight percentage: C: 0.16, Si: 0.25, Mn: 1.40, S: ≤0.005, P: ≤0.015, Als: 0.030, Ti: 0.020, the rest is iron and residual impurities;

[0039] The production process of 345MPa hot-rolled coils is: molten iron pretreatment→RH refining→LF refining→continuous casting→heating furnace heating→rolling→coiling;

[0040] Heat the furnace to 1250°C and keep it warm for 2 hours;

[0041] The rough rolling temperature target value is ≥1150°C;

[0042] The target temperature of finish rolling and initial rolling is 1050℃, and 7 passes are used for finish rolling. Except for the final pass, the reduction rate of each pass is 25%, and the reduction rate of the final pass is not less than 12%;

[0043] The thickness of the rough rolling intermediate billet is more than 50mm;

[0044] The target temperature of finish rolling and final rolling is controlled at 850°C, and the target coiling temperature after laminar cooling is 620°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com