Preparation method of core-shell structural high-transparency low-radiation heat-insulating composite nanometer coating

A composite nanomaterial and core-shell structure technology is applied in the field of preparation of high-transparency and low-radiation heat-insulating composite nanocoatings to achieve the effects of low cost, high repeatability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

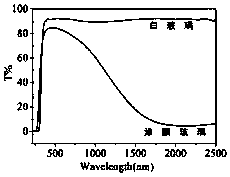

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of highly transparent and low-radiation heat-insulating nanomaterials with core-shell structure

[0035] 1) Add 2% by weight of silane coupling agent KH570 and tin antimony oxide particles to absolute ethanol, mix well and then use a high-energy ball mill for ball milling with a ball-to-material ratio of 30:1, ball milling speed 300r / min, hours, separated by filtration, washed, and dried to obtain evenly modified core layer antimony tin oxide nanoparticles, wherein the addition of antimony tin oxide particles is 200g / L;

[0036] 2) Disperse the modified core-layer antimony oxide nanoparticles obtained in step 1), tetrabutyl titanate, the precursor of shell-layer nanoparticles, and saturated ammonia solution into absolute ethanol solution, and then perform high-speed ball milling. The material ratio is 10:1, the ball milling speed is 500r / min, and the ball milling is 32 hours, then filtered, washed, and dried to obtain a composite nanomaterial with ...

Embodiment 2

[0042] Example 2 Preparation of highly transparent and low-radiation heat-insulating nanomaterials with core-shell structure

[0043] 1) Add 0.9% by weight of silane coupling agent KH550 and indium tin oxide particles to isopropanol, mix well and then use a high-energy ball mill to mill with a ball-to-material ratio of 20:1, a ball mill speed of 500r / min, and a ball mill of 2 hours, separated by filtration, washed, and dried to obtain evenly modified core layer indium tin oxide nanoparticles with particle diameters, wherein the addition of indium tin oxide particles is 180g / L;

[0044] 2) Disperse the modified core-layer indium tin oxide nanoparticles obtained in step 1), the precursor of shell-layer nanoparticles-tetraethyl titanate, and saturated ammonia solution into isopropanol solution, and then perform high-speed ball milling. The material ratio is 15:1, the ball milling speed is 400r / min, and the ball milling is 40 hours, then filtered, washed, and dried to obtain a com...

Embodiment 3

[0050] Example 3 Preparation of a high-transparency, low-emissivity heat-insulating nanomaterial with a core-shell structure

[0051] 1) Add 2.5% by weight of silane coupling agent KH560 and vanadium dioxide particles to methanol, mix evenly and use a high-energy ball mill for ball milling with a ball-to-material ratio of 25:1, ball milling speed of 400r / min, and ball milling for 4 hours. Separation by filtration, washing, and drying to obtain vanadium dioxide nanoparticles in the core layer with uniform particle size modification, wherein the addition of vanadium dioxide particles is 150g / L;

[0052] 2) Disperse the modified core-layer vanadium dioxide nanoparticles and shell-layer nanoparticle precursors-titanium sulfate and saturated ammonia solution obtained in step 1) into methanol solution, and then perform high-speed ball milling with a ball-to-material ratio of 25 : 1, ball milling speed 200r / min, ball milling 48 hours, then filter, wash, dry, obtain the composite nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com