Glass dust for back silver paste of solar battery and preparation method of glass dust

A technology for solar cells and glass powder, which is applied in the field of glass powder for silver paste on the back of solar cells and its preparation field, can solve problems such as waste of silver powder, and achieve the effects of reducing paste cost, large pull-off force and high adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of glass powder for silver paste on the back side of solar cell of the present invention comprises the following steps:

[0022]1) Raw material preparation, prepare glass powder A and glass powder B according to the ratio, put the uniformly mixed glass powder A and glass powder B into the crucible respectively, heat in a muffle furnace to 1100-1300°C, and keep warm for 30-60 minutes Finally, clamp out the crucible and pour the glass liquid into deionized water, quench the water into glass slag, filter out the glass slag and dry it for later use, the water content of the glass slag (wt%)<1%;

[0023] 2) get the glass powder A, glass powder B and inorganic additive that step 1) makes, mix by following weight percentage: glass powder A40-99, glass powder B0-60, inorganic additive 0-10; Medium=1:2-5 weight ratio weighing, add deionized water to 2 / 3 of the volume of the ball mill tank, use horizontal, vertical, planetary ball mill or high-efficiency je...

example

[0025] On March 10, 201, Zhejiang Guangda Electronic Technology Co., Ltd. made the silver paste on the back of the solar cell according to the formula in Table 1-3 below. The pull-off force test data of the solar back electrode is shown in Table 4.

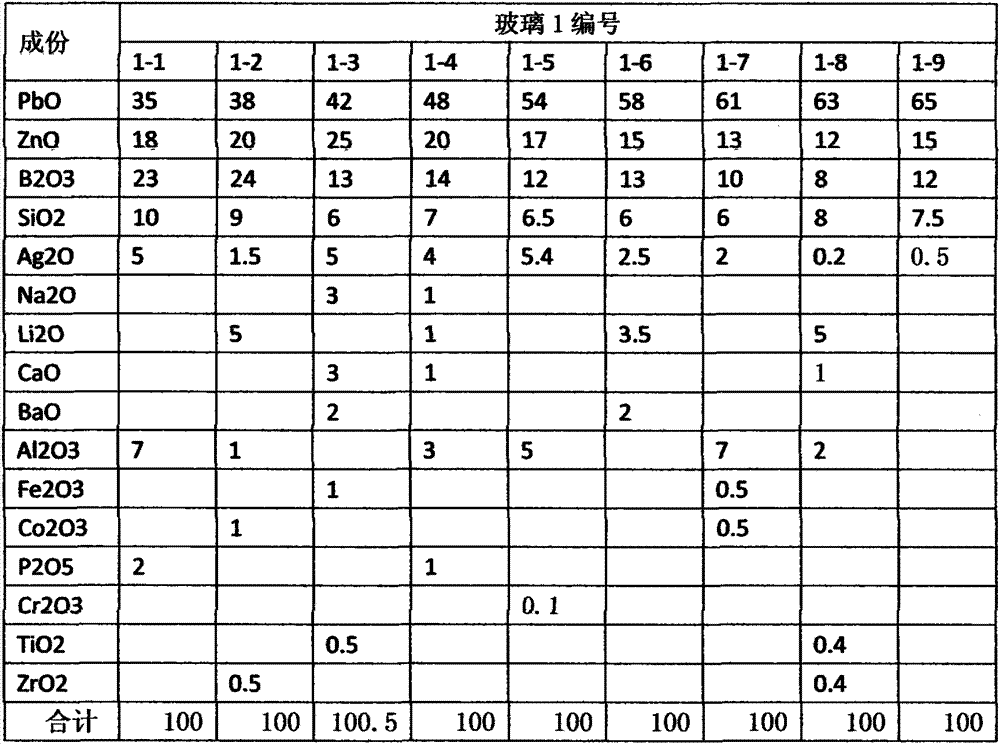

[0026] Table 1 Glass 1 Composition (mol%)

[0027]

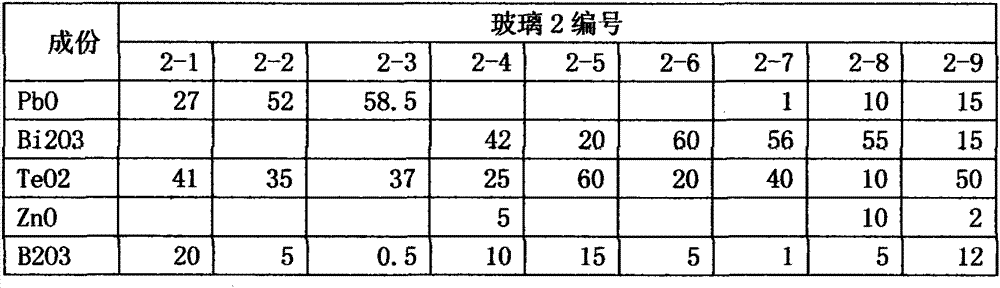

[0028] Table 2 Glass 2 Composition (mol%)

[0029]

[0030]

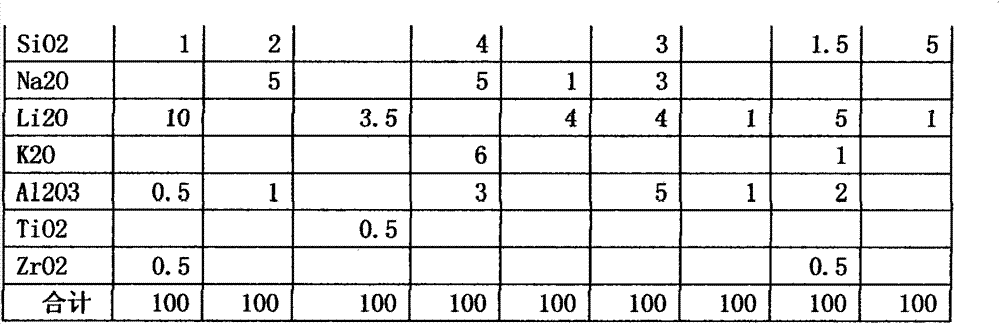

[0031] Table 3 Mixed glass powder composition

[0032]

[0033] Table 4 uses the pull-off force test data of the back electrode prepared by the slurry containing mixed glass frit

[0034]

[0035] In the slurry example of the present invention, a 156*156mm standard single crystal / polycrystalline silicon wafer is used, and the back electrode adopts a three-stage type; the slurry is printed on the silicon wafer by screen printing, and the printing wet weight is 0.025-0.0258g; sintering adopts Despatch infrared Sintering furnace, the sintering temperature is 750-850°C.

[0036] The pull-off force test u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com