Tm<3+> single-doped three-photon infrared quantum cutting microcrystalline glass as well as preparation method and application thereof

A technology of glass-ceramics and quantum tailoring, which is applied in the field of oxyfluorogermanate glass-ceramics, can solve the problems of infrared emission mechanism analysis interference, three-photon emission infrared quantum tailoring process that has not been realized and reported, and multi-energy problems. To achieve the effect of improving the photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

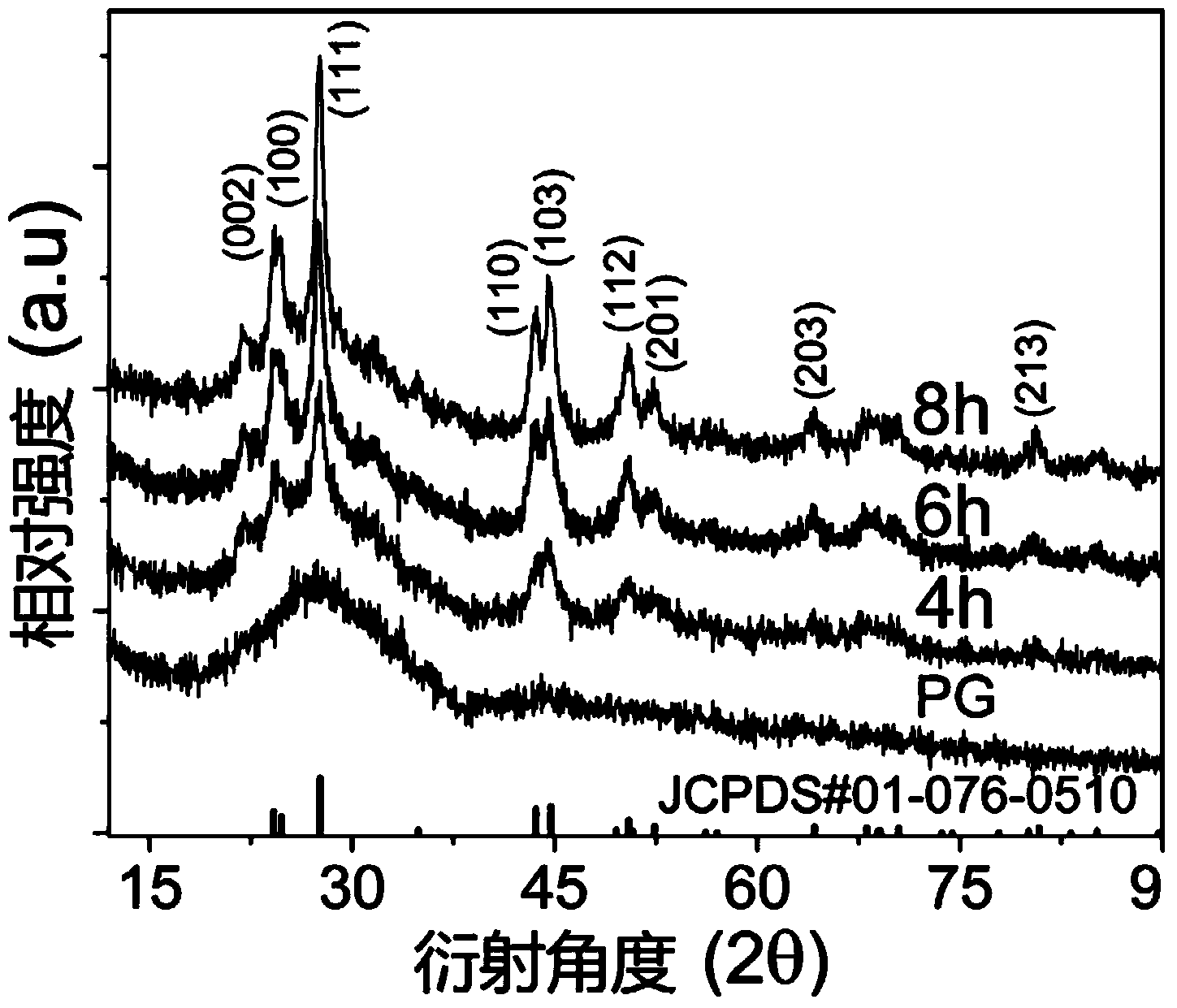

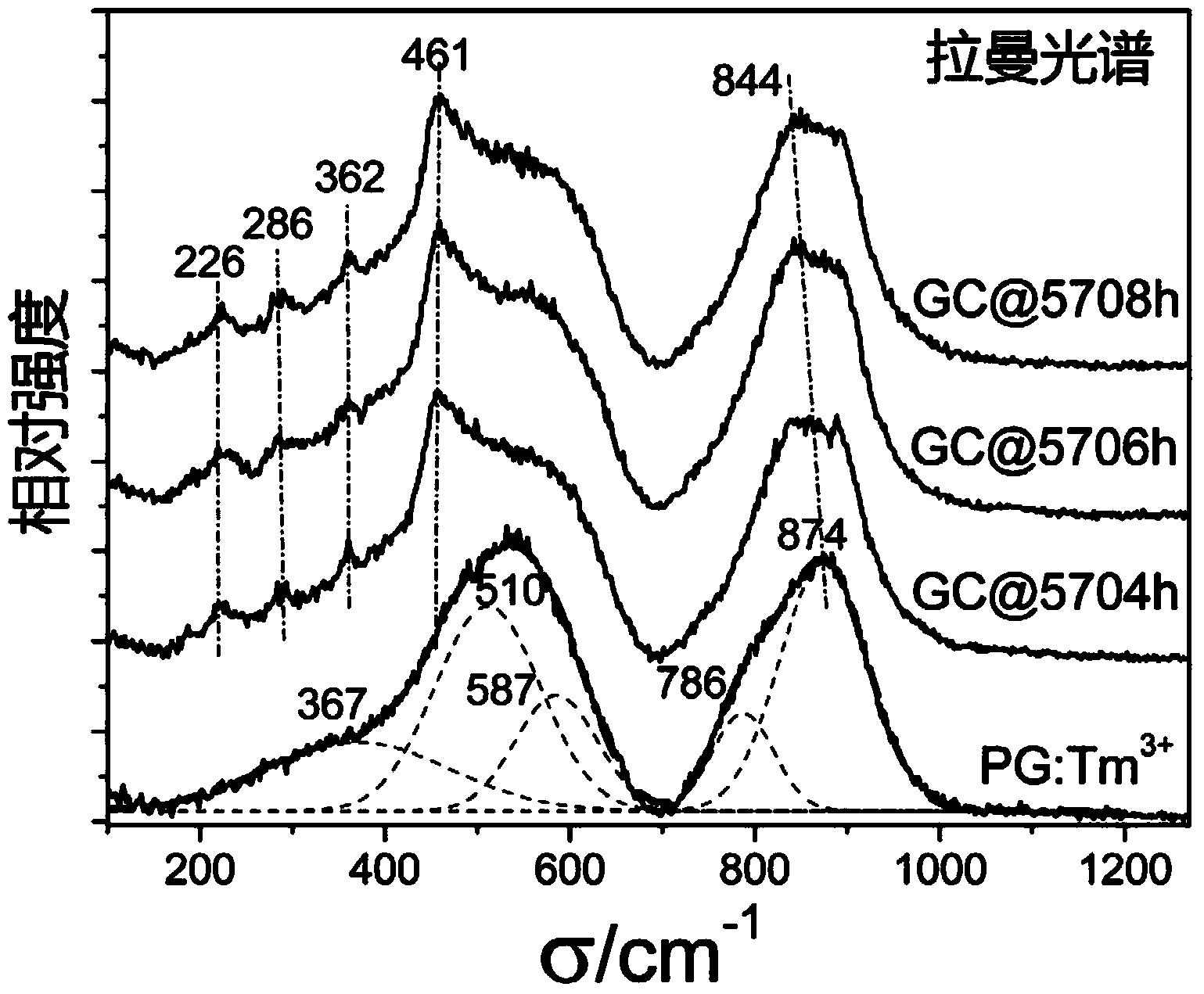

[0027] According to Tm 3+ Monodoped with LaF 3 Molar ratio composition of nanocrystalline oxyfluorogermanate glass-ceramic 50GeO 2 -20Al 2 o 3 -15LaF 3 -15LiF-xTmF 3 (x=0.50), weigh the proportion (20g) respectively according to the nominal molar composition, put 9.7681g germanium dioxide (GeO 2 ), 3.8087g aluminum oxide (Al 2 o 3 ), 5.4862g lanthanum fluoride (LaF 3 ), 0.7264g lithium fluoride (LiF) and 0.2109g thulium fluoride (TmF 3 ) The powder raw material is placed in an agate mortar for thorough mixing and uniform grinding for 30 minutes; then it is transferred to a corundum crucible and melted in a high-temperature furnace at 1350±20°C for 1 hour. Pour a uniform transparent melt with a certain fluidity into a steel mold preheated at 200±5°C for molding, keep it in a muffle furnace at 520±5°C for 2 hours, and then cool with the furnace to obtain the mother glass; finally, the mother glass is in Heat treatment at 570±1°C for 4h, 6h and 8h respectively to crysta...

Embodiment 2

[0033] According to Tm 3+ Monodoped with LaF 3 Molar ratio composition of nanocrystalline oxyfluorogermanate glass-ceramic 50GeO 2 -20Al 2 o 3 -15LaF 3 -15LiF-xTmF 3 (x=1.00), weigh the ratio (20g) respectively according to the nominal molar composition, put 9.6635g germanium dioxide (GeO 2 ), 3.7679g aluminum oxide (Al 2 o 3 ), 5.4274g lanthanum fluoride (LaF 3 ), 0.7187g lithium fluoride (LiF) and 0.4173g thulium fluoride (TmF 3 ) The powder raw material is placed in an agate mortar for thorough mixing and uniform grinding for 30 minutes; then it is transferred to a corundum crucible and melted in a high-temperature furnace at 1350±20°C for 1 hour. Pour a uniform transparent melt with a certain fluidity into a steel mold preheated at 200±5°C for molding, keep it in a muffle furnace at 520±5°C for 2 hours, and then cool with the furnace to obtain the mother glass; finally, the mother glass is in Heat treatment at 570±1°C for 6 hours to crystallize to form transparen...

Embodiment 3

[0035] According to Tm 3+ Monodoped with LaF 3 Molar ratio composition of nanocrystalline oxyfluorogermanate glass-ceramic 50GeO 2 -20Al 2 o 3 -15LaF 3 -15LiF-xTmF 3 (x=0.25), take proportioning (20g) respectively according to nominal molar composition, put 9.8205g germanium dioxide (GeO 2 ), 3.8291g aluminum oxide (Al 2 o 3 ), 5.5156g lanthanum fluoride (LaF 3 ), 0.7303g lithium fluoride (LiF) and 0.1060g thulium fluoride (TmF 3) The powder raw material is placed in an agate mortar for thorough mixing and uniform grinding for 30 minutes; then it is transferred to a corundum crucible and melted in a high-temperature furnace at 1350±20°C for 1 hour. Pour a uniform transparent melt with a certain fluidity into a steel mold preheated at 200±5°C for molding, keep it in a muffle furnace at 520±5°C for 2 hours, and then cool with the furnace to obtain the mother glass; finally, the mother glass is in Heat treatment at 570±1°C for 6 hours to crystallize to form transparent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com