Wastewater treatment method for basic zinc carbonate produced by using wet method

A zinc carbonate and alkaline technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as slow absorption efficiency, achieve low production cost, reduce environmental pollution, and process simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

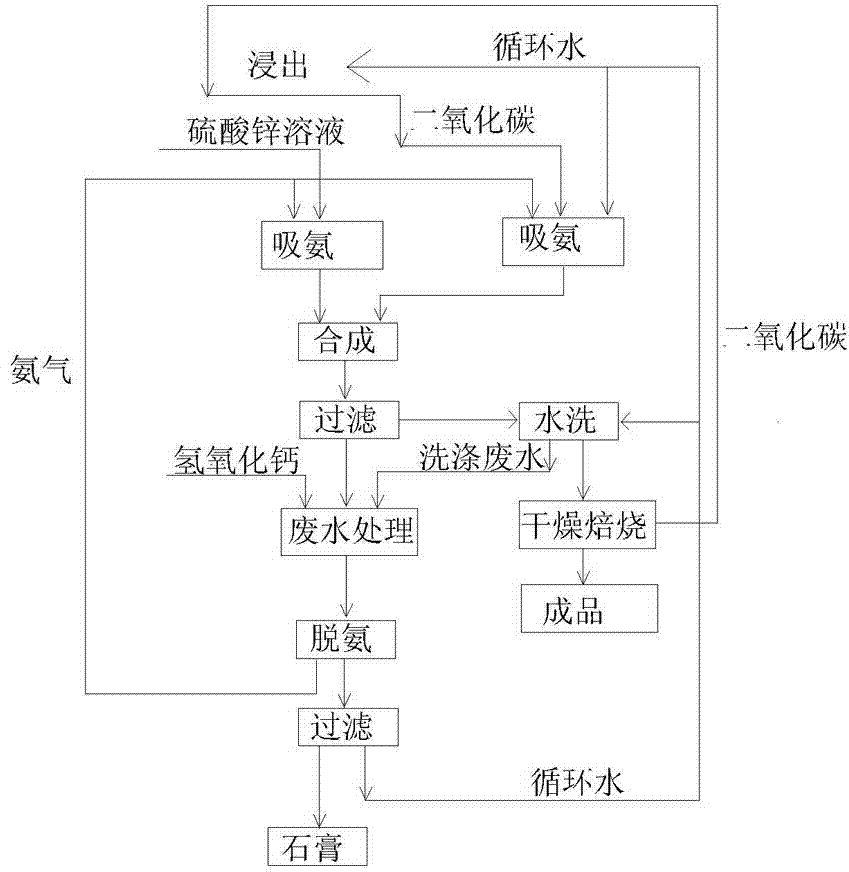

Image

Examples

Embodiment 1

[0024] Put 2 cubic meters of ammonium sulfate-containing wastewater discharged from the production of active zinc oxide and basic zinc carbonate, and 3 cubic meters of washed wastewater into the reaction tank, add calcium hydroxide emulsion (milk of lime) and stir evenly, control the pH value to 11, and stir the reaction After the end, use a pump to send it into the deamination tower and use a blower to blow hot air at 60°C to blow out the ammonia. The blown ammonia gas is absorbed in two ways: ① into the absorption tower for roasting section ((ZnCO 3 .2Zn(OH) 2 ) roasting to decompose ZnO+CO 2 ). The released CO 2 Absorb and react with water to obtain carbonated ammonia water (ammonium bicarbonate). The reaction formula is as follows, NH 4 OH+CO 2 =NH 4 HCO 3 . ② Send it to the absorption tower, absorb it with a refined zinc sulfate solution, and spray it with a zinc sulfate solution containing 120 g / L of zinc. Detect the zinc content of the zinc sulfate solution at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com