Fluoride brazing flux for copper-aluminum dissimilar metals and preparation method thereof

A technology of dissimilar metals and fluorides, which is applied in the field of fluoride flux for copper and aluminum dissimilar metals and its preparation, can solve the problems of flux drop and inconvenience, and achieve the advantages of reduced flux cost, good activity and low melting point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

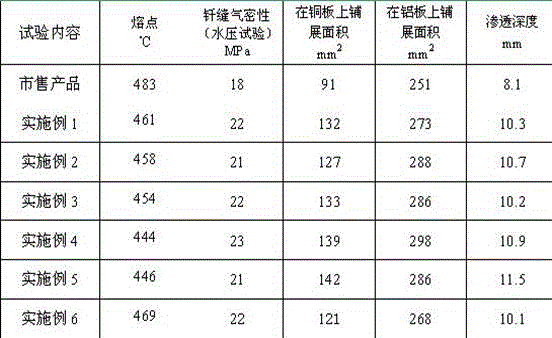

Embodiment 1

[0019] The copper-aluminum dissimilar metal fluoride flux of the present embodiment consists of the following components:

[0020] The mass percentage of each component of the flux is 43.75% of cesium fluoride, 35% of aluminum trifluoride, 21% of potassium fluoride, and 0.25% of copper difluoride, and the total mass percentage is 100%.

[0021] Prepare as follows:

[0022] 1. Weigh cesium fluoride, aluminum trifluoride, potassium fluoride, copper difluoride, zinc difluoride, lithium fluoride, ZnAl metal powder and other powders in proportion and mix them in a mortar;

[0023] 2. Add an appropriate amount of deionized water and grind to a paste;

[0024] 3. Transfer the paste flux to an oven for drying;

[0025] 4. Grind the dried flux into solder powder.

[0026] Zn-15Al is selected as the filler metal and brazed with flux. It is suitable for brazing copper-aluminum joints. It has good seam filling performance during brazing, and the brazed pipeline has excellent airtight p...

Embodiment 2

[0028] The copper-aluminum dissimilar metal fluoride flux of the present embodiment consists of the following components:

[0029] Cesium fluoride 42%, aluminum trifluoride 39%, potassium fluoride 18%, copper difluoride 0.15%, zinc difluoride 0.2%, pure zinc powder 0.65%, the total mass percentage is 100%.

[0030] Prepare brazing flux according to the preparation steps in Example 1, select Zn-15Al as the filler metal, and braze with the brazing flux, which is suitable for brazing copper-aluminum joints. The seam filling performance is good during brazing, and after brazing The pipeline has excellent airtight performance.

Embodiment 3

[0032] The copper-aluminum dissimilar metal fluoride flux of the present embodiment consists of the following components:

[0033] Cesium fluoride 37.6%, aluminum trifluoride 30.5%, potassium fluoride 29.5%, copper difluoride 0.45%, zinc difluoride 0.45%, lithium fluoride 1.5%, the total mass percentage is 100%.

[0034] Prepare brazing flux according to the preparation steps in Example 1, select Zn-15Al as the filler metal, and braze with the brazing flux, which is suitable for brazing copper-aluminum joints. The seam filling performance is good during brazing, and after brazing The pipeline has excellent airtight performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com