A kind of preparation method of hydrotreating catalyst

A kind of technology of hydrotreating and catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

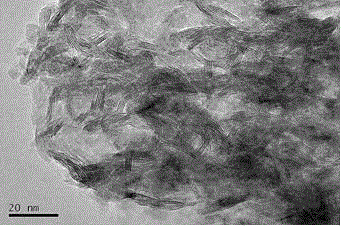

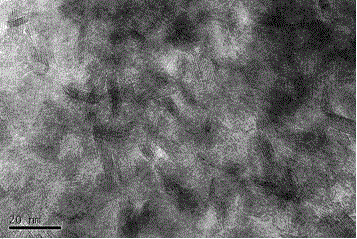

Image

Examples

Embodiment 1

[0039] Using silicon modified pseudo-boehmite dry rubber powder to prepare the catalyst precursor, weigh 200 g of the above-mentioned dry rubber powder and 100 g of SB powder, add 4 g each of sesame powder and citric acid, mix well and add acidic solution. The concentration of nitric acid in the acidic solution is 2wt%, and the rest is distilled water. Rolled for 15-25 minutes, extruded with clover orifice plates with a diameter of 1.7mm, dried at 120°C for 12 hours, and calcined at 550°C for 3 hours to obtain a catalyst carrier, namely Z-1, with the following properties: pore volume 0.72 ml / g, the specific surface area is 342m 2 / g.

Embodiment 2

[0041] Weigh an appropriate amount of carrier Z-1, and impregnate carrier Z-1 with an impregnation solution containing Mo, Ni, P and asparagine in an equal volume. The composition of the impregnation solution is MoO 3 The content of NiO is 88.5g / 100ml, the content of NiO is 15g / 100ml, the content of P is 2.3g / 100ml, the amount of asparagine is 13.2g / 100ml, and the amount of asparagine is the molar ratio of Ni atom in the final catalyst It is 0.5:1. The ultrasonic impregnation method is used for impregnation. The ultrasonic power is 15W / ml, the frequency is 50kHZ, the temperature is 45°C, and the time is 20min. After soaking, it is aged at room temperature for 10 hours, and dried at 115°C for 3 hours to obtain catalyst C-1. .

Embodiment 3

[0043] Weigh an appropriate amount of catalyst carrier Z-1, and use an impregnating solution containing Mo, Ni, P, 2-amino-1,3 propanediol, and the composition of the impregnating solution is MoO 3 The content of NiO is 89.5g / 100ml, the content of NiO is 15g / 100ml, the content of P is 2.5g / 100ml, the amount of 2-amino-1,3 propanediol is 14.58g / 100ml, of which 2-amino-1,3 propanediol is The molar ratio of the amount to the Ni content in the final catalyst is 0.8:1. The ultrasonic impregnation method is used for impregnation. The ultrasonic power is 15W / ml, the frequency is 50kHZ, the temperature is 45℃, and the time is 30min. After immersion, it is aged at room temperature for 10 hours and dried at 120℃ for 3 hours to obtain catalyst C-2. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com