Bidentate Chiral Chromatographic Silanes and Chiral Stationary Phases Containing Tartrate Skeleton

A chiral and silane technology, applied in the field of chromatographic separation materials, can solve the problems of weak force of coating-type stationary phase, etc., achieve good chiral separation effect, simple synthesis method, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

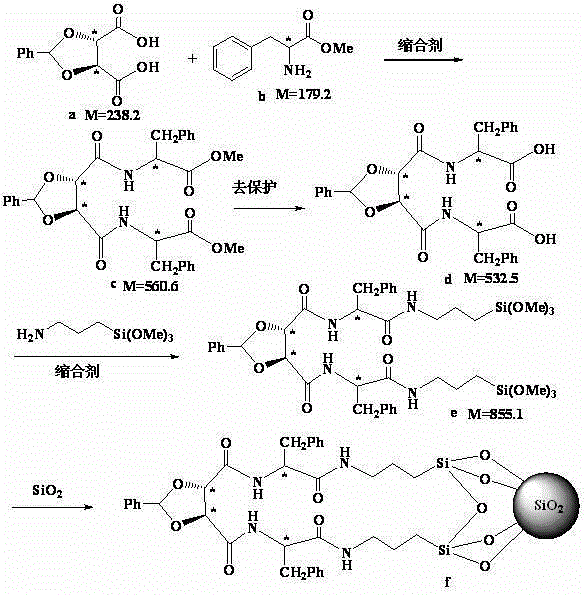

Method used

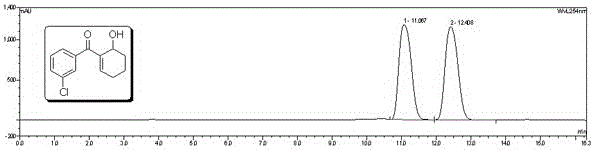

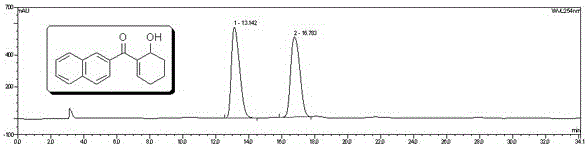

Image

Examples

Embodiment 1

[0025] Source of raw material 1

[0026] Dimethyl (+)-2,2-dimethyl-1,3-dioxolane-4,5-dicarboxylate (M = 190) Alkaline hydrolysis to obtain (+)-2,2-dimethyl-1,3-dioxolane-4,5-dicarboxylic acid dicarboxylic acid (M = 178).

[0027] Silane preparation

[0028] (1) Preparation of Intermediate 3

[0029] in N 2 Under protection, the raw material of 10.3g (50mmol) ( 1 ), 19.8g (110mmol) of raw material ( 2 ) was dissolved in 100ml of dichloromethane, continued stirring for 5-10 minutes, added 110mmol HBTU, 110mmol HOBT, 100ml DIEA, and stirred at room temperature for 2h. The reaction was detected by TLC point plate until the reactant ( 1 )disappear. The dichloromethane was removed by rotary evaporation, and the concentrate was added to refrigerated ether for precipitation, washed three times with refrigerated ether, and the intermediate ( 3 ). MS:m / z513.55[M+H] + . Elemental analysis: C%63.46; H%6.23; N%5.41.

[0030] (2) Preparation of Intermediate 4

[0031] ...

Embodiment 2

[0044] Silane preparation

[0045] (1) Preparation of Intermediate C

[0046] in N 2 Under protection, the raw material of 9.5g (40mmol) ( a) , 15g (84mmol) of raw material ( b) Dissolve in 100ml DMF, continue stirring for 5-10 minutes, add 84mmol HBTU, 84mmol HOBT, 50ml DIEA, and stir at room temperature for 2 hours. The reaction was detected by TLC point plate until the reactant ( a) disappear. The solvent was removed by rotary evaporation, the concentrate was precipitated by adding refrigerated ether, and washed three times with cold ether to obtain the intermediate ( c ). MS:m / z561.59[M+H] + . Elemental analysis: C%66.38; H%5.64; N%4.97.

[0047] (2) Preparation of intermediate d

[0048] Take by weighing 11.2g (20mmol) intermediate ( c ), add 100ml of 1N NaOH solution and 50ml of toluene, stir magnetically at 80°C for 2-3 hours, cool to room temperature, drop in 1N dilute hydrochloric acid to adjust the pH to neutral, evaporate to dryness under reduced pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com