Method for preparing aluminium nitride copper-coated ceramic substrate

A technology of aluminum nitride copper cladding, aluminum nitride ceramics, applied in semiconductor/solid state device manufacturing, electrical components, circuits, etc. problem, to achieve the effect of solving surface bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Raw material cleaning

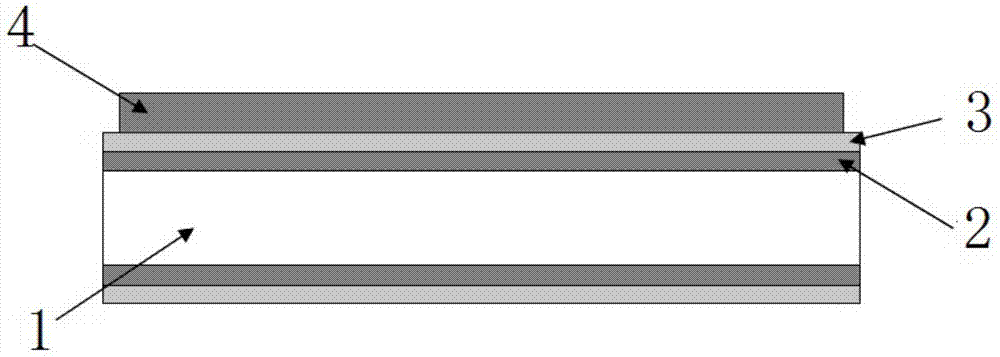

[0029] The copper sheet 4 and the aluminum nitride ceramic 1 are cleaned to remove impurities on the surface of the material by using an acid-base solution and deionized water through processes such as ultrasonic cleaning, spraying, and pre-dehydration.

[0030] (2) Porcelain pre-oxidation

[0031] The oxidation temperature is set at 1000°C to 1300°C, the oxidation time is 0.5h to 24h, the atmosphere is an oxidation atmosphere under the protection of nitrogen, the nitrogen and oxygen content ratio is 4:1 to 10:1, and the thickness of the aluminum oxide layer 2 is 1 μm to 100 μm .

[0032] (3) Surface modification treatment

[0033] On the surface of the pre-oxidized aluminum nitride ceramic 1, the metal modification layer 3 is evenly coated by screen printing, and the metal modification layer 3 is copper-containing oxide including CuO or Cu 2 O or a mixture of the two, the thickness of the coating is 1 μm to 50 μm, and the sintering is car...

Embodiment 2

[0040] (1) Raw material cleaning

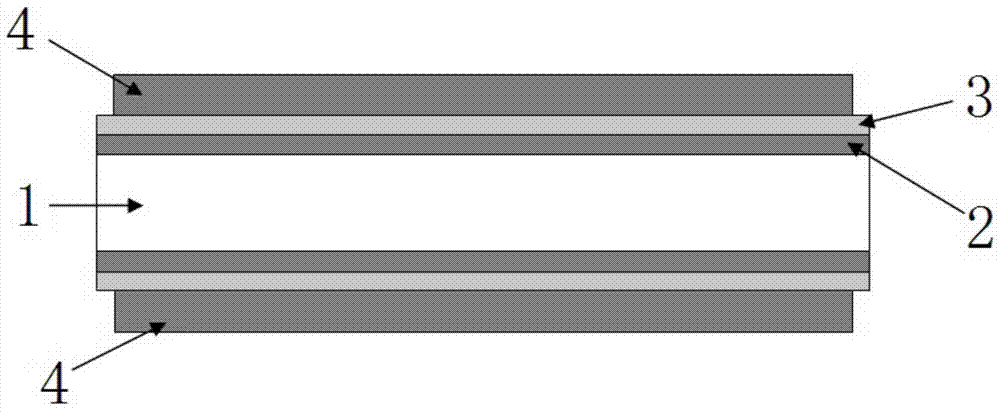

[0041] The copper sheet 4 and the aluminum nitride ceramic 1 are cleaned to remove impurities on the surface of the material by using an acid-base solution and deionized water through processes such as ultrasonic cleaning, spraying, and pre-dehydration.

[0042] (2) Porcelain pre-oxidation

[0043] The oxidation temperature is set at 1000°C to 1300°C, the oxidation time is 0.5h to 24h, the atmosphere is an oxidation atmosphere under the protection of nitrogen, the nitrogen and oxygen content ratio is 4:1 to 10:1, and the thickness of the aluminum oxide layer 2 is 1 μm to 100 μm .

[0044] (3) Surface modification treatment

[0045] On the surface of the pre-oxidized aluminum nitride ceramic 1, the metal modification layer 3 is evenly coated by screen printing, and the metal modification layer 3 is copper-containing oxide including CuAlO 2 or CuAl 2 o 4 Or a mixture of the two, the thickness of the coating is 1 μm to 50 μm, and the sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com