Method for preparing beta-amylase and soybean oligosaccharides

A soybean oligosaccharide and amylase technology is applied in the comprehensive application field of soybean protein wastewater, which can solve the problems of high BOD and COD, low separation product concentration and high separation cost, achieve good acid resistance and temperature resistance, and save sewage. The effect of processing cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 prepares beta-amylase and soybean oligosaccharide simultaneously with soybean protein wastewater

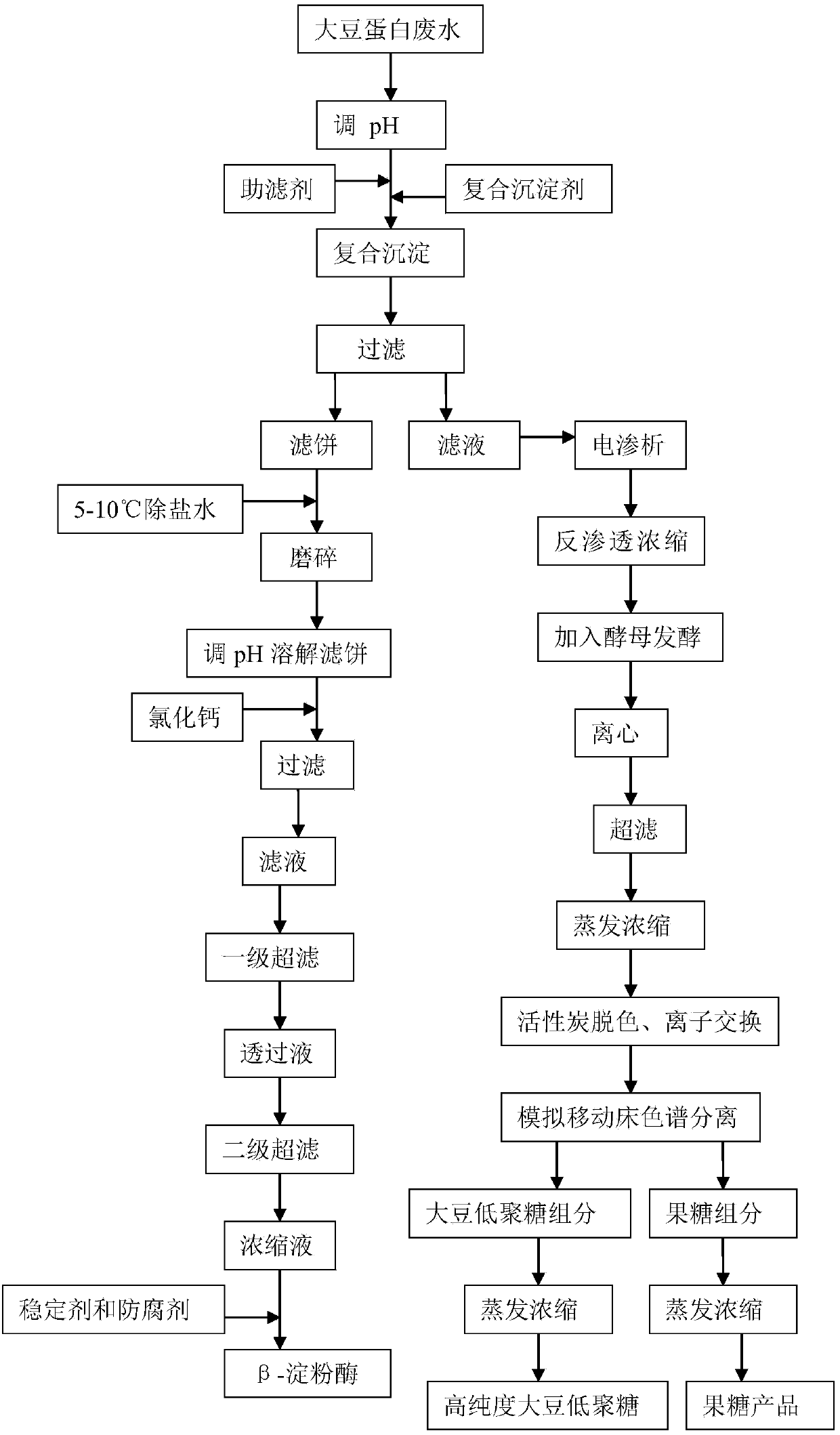

[0033] The steps are as follows (process flow such as figure 1 shown):

[0034] (1) Composite precipitation

[0035] Take 1 ton of soybean protein wastewater, in which the β-amylase activity is 5237u / mL, adjust the pH to 5.0, add 1.0% diatomite of soybean protein wastewater, and then add 0.3% polyacrylic acid of soybean protein wastewater, and after 20 minutes Filter to obtain filter cake and filtrate.

[0036] (2) Separation of β-amylase

[0037] Add the filter cake in step 1 to 8 times the mass of desalted water at 5-10°C for grinding and dispersion, then adjust the pH to 8.0 to dissolve, then add calcium chloride with a mass of 6% of the filter cake to precipitate the added polyacrylic acid, and then Filtrate to obtain filtrate and filter residue.

[0038] (3) Primary ultrafiltration

[0039] Pass the filtrate in step 1 through an ultrafiltration memb...

Embodiment 2

[0048] Embodiment 2 prepares beta-amylase and soybean oligosaccharide simultaneously with soybean protein wastewater

[0049] Proceed as follows:

[0050] (1) Composite precipitation

[0051] Take 1 ton of soybean protein wastewater, in which the activity of β-amylase is 5237u / mL, adjust the pH to 4.0, add 0.7% perlite of soybean protein wastewater, and then add 0.2% polyacrylic acid of soybean protein wastewater, filter after 20min , to obtain filter cake and filtrate.

[0052] (2) Separation of β-amylase

[0053] Add the filter cake in step 1 to 6 times the mass of desalted water at 5-10°C for grinding and dispersion, then adjust the pH to 7.0 to dissolve, then add calcium carbonate with a mass of 4% of the filter cake to precipitate the added polyacrylic acid, and then filter Obtain filtrate and filter residue.

[0054] (3) Primary ultrafiltration

[0055] Pass the filtrate in step 1 through an ultrafiltration membrane with a molecular weight cut-off of 80,000 to 90,00...

Embodiment 3

[0064] Embodiment 3 prepares beta-amylase and soybean oligosaccharide simultaneously with soybean protein wastewater

[0065] Proceed as follows:

[0066] (1) Composite precipitation

[0067] Take 1 ton of soybean protein wastewater, in which the β-amylase activity is 5237u / mL, adjust the pH to 3.0, add 0.5% diatomite of soybean protein wastewater, and then add 0.1% polyacrylic acid of soybean protein wastewater, and after 30min Filter to obtain filter cake and filtrate.

[0068] (2) Separation of β-amylase

[0069] Add the filter cake in step 1 to 5 times the mass of desalted water at 5-10°C for grinding and dispersion, then adjust the pH to 6.0 to dissolve, then add calcium carbonate with a mass of 3% of the filter cake to precipitate the added polyacrylic acid, and then filter Obtain filtrate and filter residue.

[0070] (3) Primary ultrafiltration

[0071] Pass the filtrate in step 1 through an ultrafiltration membrane with a molecular weight cut-off of 80,000 to 90,0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com