A control method for dual-motor electro-hydraulic brake system based on force control

An electro-hydraulic composite and braking system technology, applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of increased control difficulty, achieve good brake pedal feel, and ensure the effect of brake pedal feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

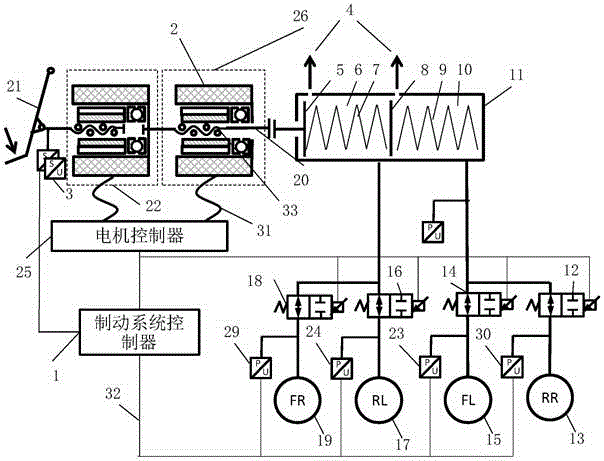

[0035] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

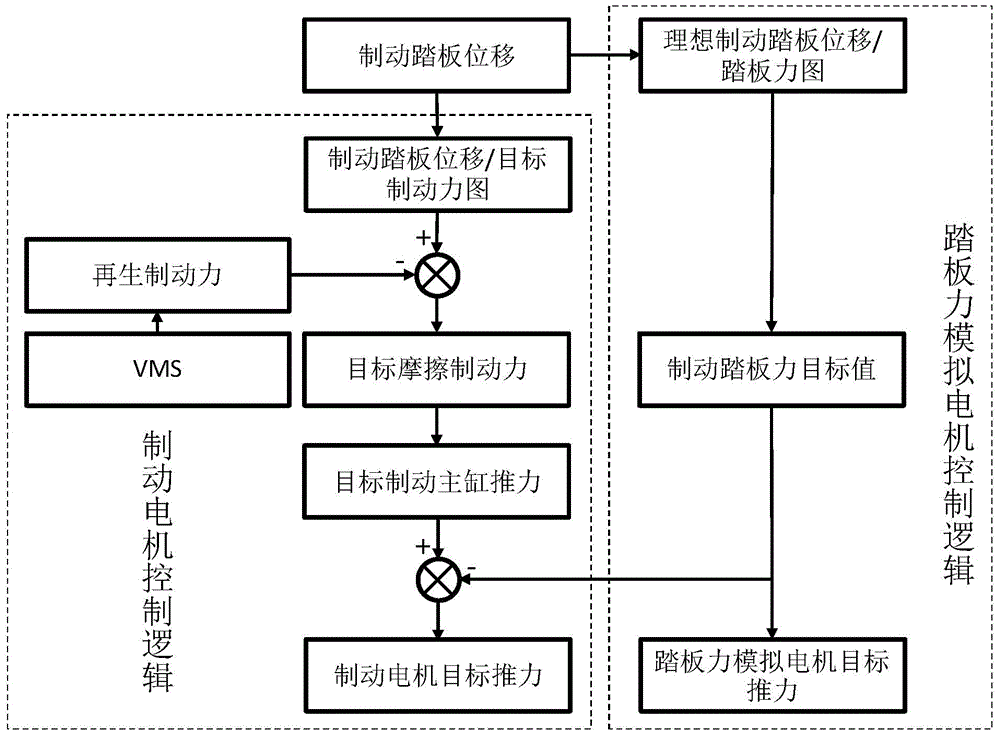

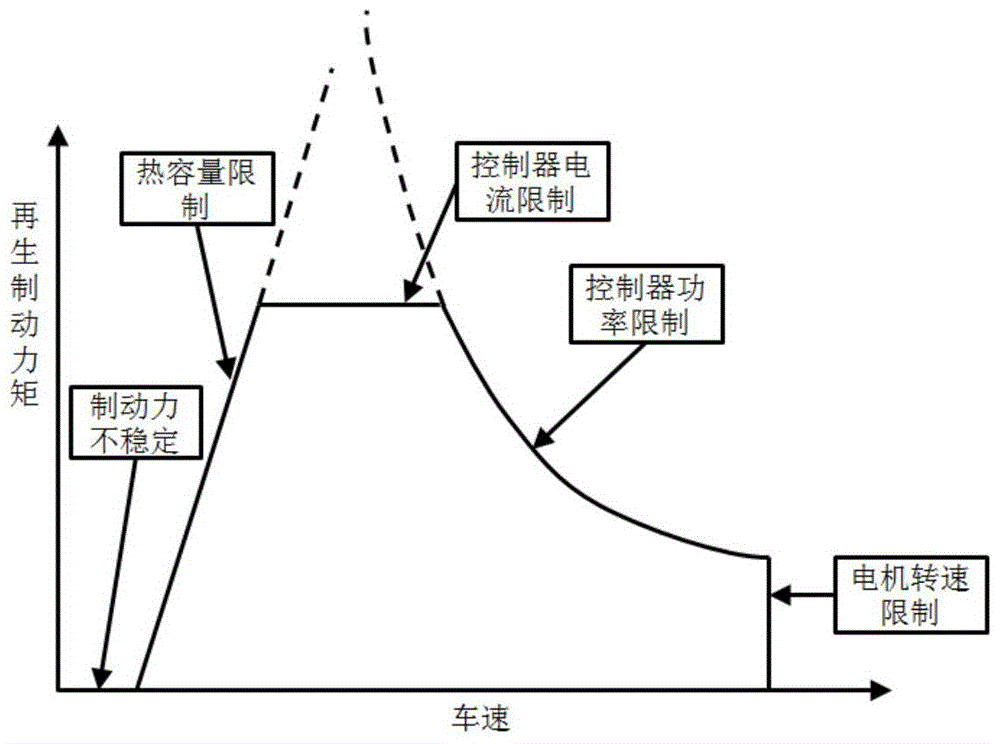

[0036] When the driver steps on the brake pedal to generate a corresponding brake pedal displacement, the system tries to obtain the target total vehicle braking force requirement by querying the brake pedal displacement / brake pedal. At the same time, VMS obtains the maximum regenerative braking force through the driving state of the vehicle. The variation of maximum regenerative braking force with vehicle speed is as follows: image 3shown. When the vehicle is running at a very low speed, there are many fluctuations because the torque of the electric motor is unstable at low speed. Therefore, when the vehicle is at a very low speed, regenerative braking usually does not work, and the braking of the vehicle is all done by the traditional hydraulic braking system. And when the vehicle is in a low-speed state, because the working efficiency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com