Material for purifying micromolecule poisonous gases as well as preparation method thereof

A technology for purifying toxic gases and materials, applied in separation methods, chemical instruments and methods, and other chemical processes, to achieve the effects of easy-to-master technical operations, improved service life, and increased protection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

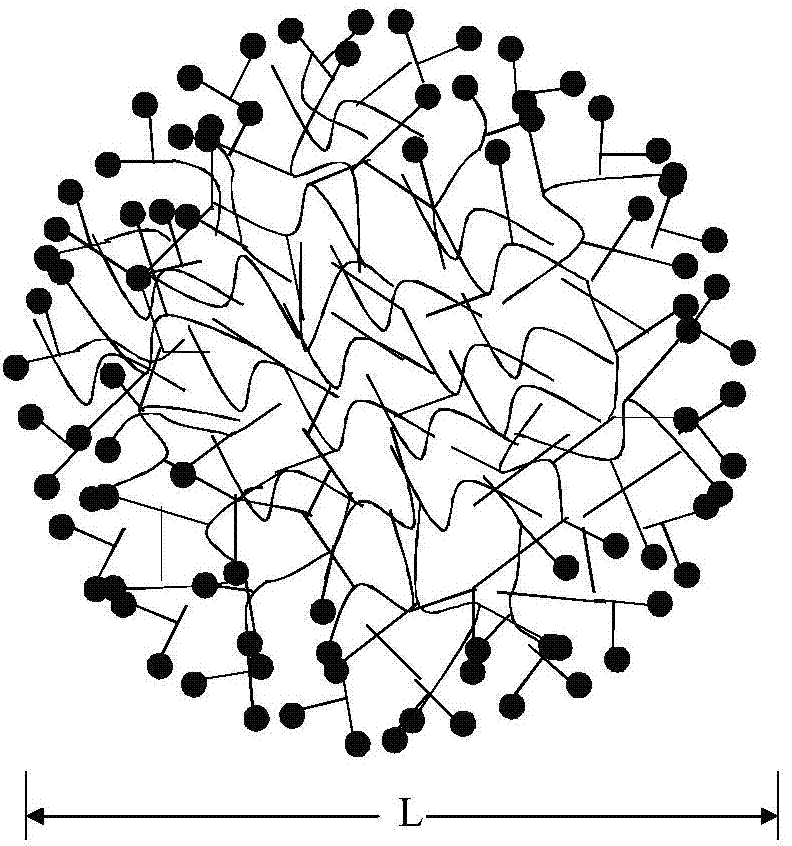

[0020] The preparation method for the small molecule toxic gas purification material proposed by the present invention comprises the following steps:

[0021] (1) Dissolve lactulose-oligosaccharide or glucose, lanthanide metal nitrate and acrylamide or butene amide in water to obtain a solution, in which lactulose-oligosaccharide or glucose, cerium nitrate or lanthanum nitrate, acrylamide or butene The molar concentration (mol / L) of the aqueous solution of each component of the amide is: 0.01~1, 0.015~1, 0.02~1, adjust the pH value to 8~12 with urea or ammonia water to obtain a colloid, stir for 3~12 hours, and React at 120-300°C for 10-120 hours, filter to obtain the precipitate, wash the precipitate 5-8 times with water, wash with absolute ethanol 5-8 times, dry at 80°C for 4-8 hours, then dry at 450-600°C Calcining at lower temperature for 6 to 24 hours to obtain a spherical carrier;

[0022] (2) Dissolve one or more nitrates of metal copper, zinc, nickel, cobalt or silver...

Embodiment 1

[0025] Example 1 Preparation of Toxic Gas Purification Material: AgO / CeO 2 : 5.0% AgO loading

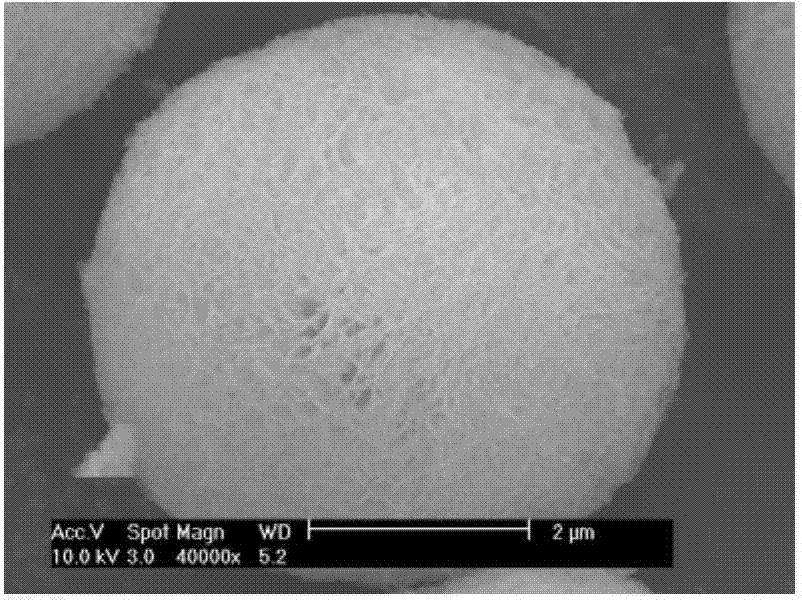

[0026] (1) Dissolve glucose, cerium nitrate and crotonamide in water to obtain a solution, wherein the aqueous molar concentrations (mol / L) of the components of glucose, cerium nitrate and crotonamide are: 0.025, 0.03, 0.03, respectively, Adjust the pH value to 9 with ammonia water to obtain a colloid, stir for 4 hours, react at 140°C for 40 hours, filter to obtain a precipitate, wash the precipitate with water 6 times, wash with absolute ethanol 6 times, and dry at 80°C for 5 hours , calcined at 500°C for 10 hours to obtain bright yellow spherical carrier CeO 2 , the microscopic morphology of the spherical carrier is as follows figure 2 shown;

[0027] (2) Dissolve metallic silver nitrate in water to make solution A, the molar concentration (mol / L) of metal oxide in solution A is 0.1, put the spherical carrier prepared in step (1) into solution A Stir to obtain suspension B, t...

Embodiment 2

[0029] Example 2 Preparation of toxic gas purification material: AgO / CeO 2 : 10.0% AgO loading

[0030](1) Dissolve glucose, cerium nitrate and crotonamide in water to obtain a solution, wherein the molar concentrations (mol / L) of the aqueous solutions of the components of glucose, cerium nitrate and crotonamide are: 0.1, 0.11, 0.13, respectively, Adjust the pH value to 9.5 with ammonia water to obtain a colloid, stir for 4 hours, react at 160°C for 60 hours, filter to obtain a precipitate, wash the precipitate with water 6 times, wash with absolute ethanol 6 times, and dry at 80°C for 5 hours , calcined at 550°C for 10 hours to obtain bright yellow spherical carrier CeO 2 ;

[0031] (2) Dissolve metallic silver nitrate in water to make solution A, the molar concentration (mol / L) of metal oxide in solution A is 0.5, put the spherical carrier prepared in step (1) into solution A Stir to obtain suspension B, the mass ratio of active metal oxide and spherical carrier in suspen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com