Acyclovir cream

A technology of acyclovir cream and total amount, which is applied in the direction of ointment delivery, emulsion delivery, skin diseases, etc., can solve the problems of poor absorption, etc., and achieve good patient tolerance, no adverse reactions, and convenient medication Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

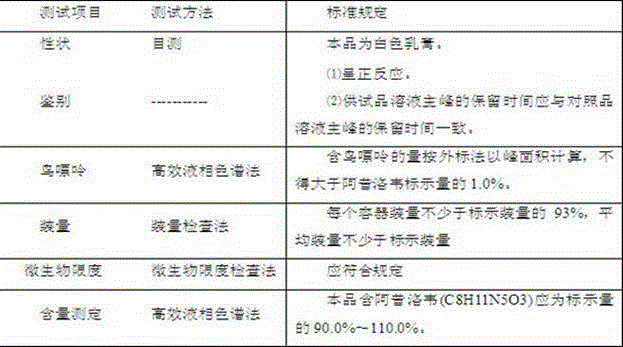

Image

Examples

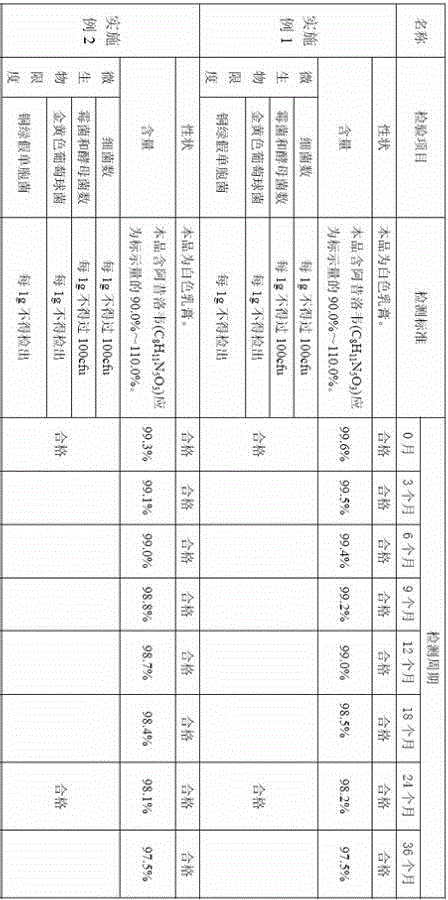

Embodiment 1

[0016] A kind of acyclovir emulsifiable paste, be made up of each raw material that following total amount is 100g: acyclovir 2g, cetostearyl alcohol 4g, glyceryl monostearate 2g, white vaseline 4g, glycerin 4g, 0.5 g of sodium lauryl sulfate, 0.2 g of ethylparaben, 0.5 g of dimethyl sulfoxide, 0.2 g of 5 wt % benzalkonium bromide solution, and the balance is purified water.

[0017] Preparation:

[0018] 1) Prepare the water phase: Put the water phase materials glycerin, sodium lauryl sulfate, ethylparaben, dimethyl sulfoxide, purified water, 5wt% benzalkonium bromide solution and acyclovir into the water phase in proportion In the tank, stir at 90°C for 20 minutes until uniform, then set aside;

[0019] 2) Prepare the oil phase: add cetostearyl alcohol, glyceryl monostearate and white petrolatum into the oil phase tank in proportion to the oil phase materials, stir at 82°C for 20 minutes until uniform, and set aside;

[0020] 3) Preparation of cream: transfer the above-men...

Embodiment 2

[0022] A kind of acyclovir emulsifiable paste, be made up of each raw material that following total amount is 100g: acyclovir 3g, cetostearyl alcohol 6g, glyceryl monostearate 5g, white vaseline 6g, glycerin 6g, 1 g of sodium lauryl sulfate, 0.3 g of ethylparaben, 1 g of dimethyl sulfoxide, 0.5 g of 5 wt % benzalkonium bromide solution, and the balance is purified water.

[0023] Preparation:

[0024] 1) Prepare the water phase: Put the water phase materials glycerin, sodium lauryl sulfate, ethylparaben, dimethyl sulfoxide, purified water, 5wt% benzalkonium bromide solution and acyclovir into the water phase in proportion In the tank, stir at 95°C for 25 minutes until uniform, then set aside;

[0025] 2) Prepare the oil phase: add cetostearyl alcohol, glycerol monostearate and white petrolatum into the oil phase tank in proportion to the oil phase materials, stir at 85°C for 25 minutes until uniform, and set aside;

[0026] 3) Preparation of cream: transfer the above-mention...

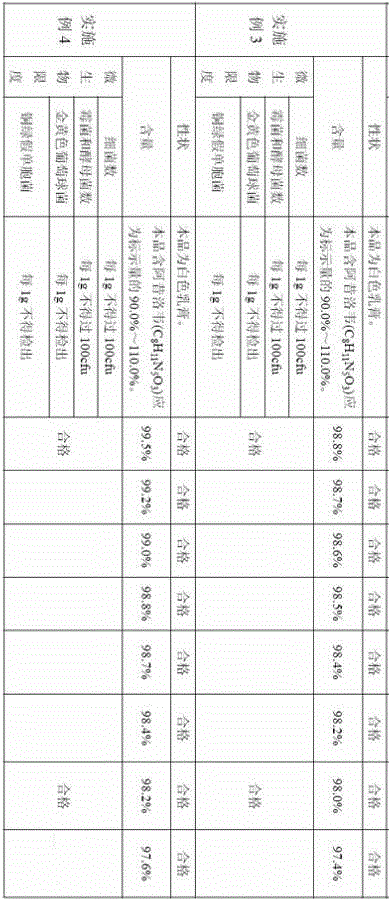

Embodiment 3

[0028] A kind of acyclovir emulsifiable paste, be made up of each raw material that following total amount is 100g: acyclovir 4g, cetostearyl alcohol 8g, glyceryl monostearate 8g, white vaseline 8g, glycerin 8g, 1.5 g of sodium lauryl sulfate, 0.4 g of ethylparaben, 1.5 g of dimethyl sulfoxide, 0.8 g of 5 wt % benzalkonium bromide solution, and the balance is purified water.

[0029] Preparation:

[0030] 1) Prepare the water phase: Put the water phase materials glycerin, sodium lauryl sulfate, ethylparaben, dimethyl sulfoxide, purified water, 5wt% benzalkonium bromide solution and acyclovir into the water phase in proportion In the tank, stir at 95°C for 20 minutes until uniform, then set aside;

[0031] 2) Prepare the oil phase: add cetostearyl alcohol, glyceryl monostearate and white petrolatum into the oil phase tank in proportion to the oil phase materials, stir at 87°C for 20 minutes until uniform, and set aside;

[0032] 3) Preparation of cream: transfer the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com