Gamma ray non-destructive testing cable concealed section detection device and method for realizing detection

A non-destructive testing and gamma ray technology, which is applied in the direction of measuring devices, using wave/particle radiation, and using radiation for material analysis, etc., can solve the problems that the cable anchorage area cannot be detected, etc., and achieve the effect of long-term storage and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

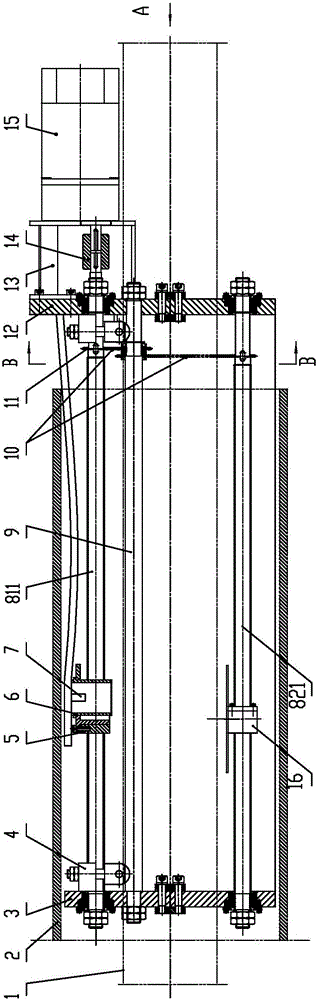

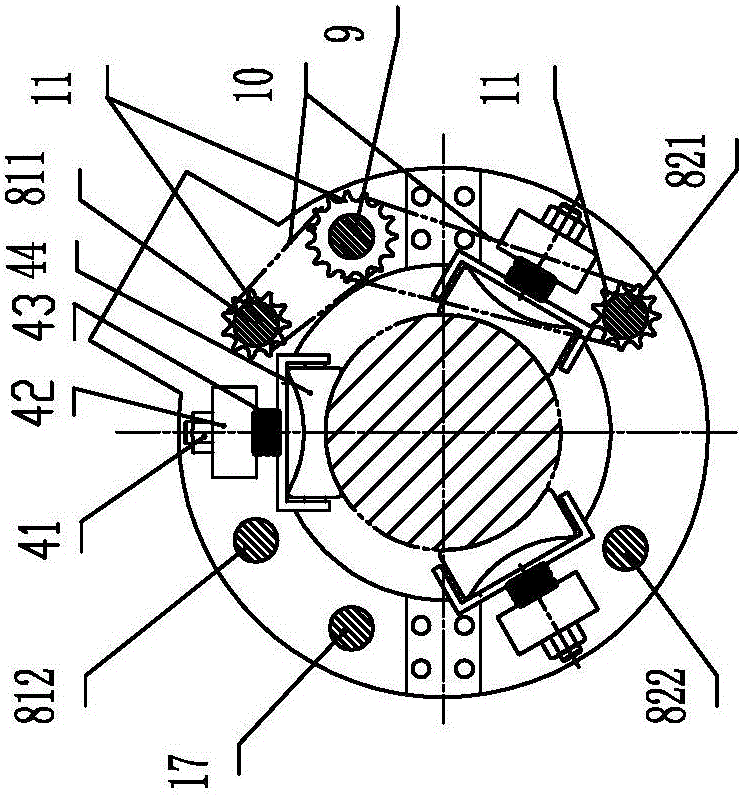

[0038] A gamma-ray non-destructive detection cable concealed section detection device, including two parts: a gamma-ray flaw detector and a probe detection creeping device; the gamma-ray flaw detector is an existing small-sized gamma-ray flaw detector in the market;

[0039] The crawling device for probe detection includes a probe mounting support, a steel structure bracket and a power transmission mechanism;

[0040] The power transmission mechanism includes a power source, a sprocket, and a chain;

[0041]The steel structure bracket includes an upper half bracket, a lower half bracket, and semicircular front and rear end plates, and the upper half bracket consists of 1 drive screw, 1 guide rod, 2 pull rods and 2 semicircular front and rear ends The lower half bracket is composed of a transmission screw, a guide rod and two semicircular front and rear end plates, the upper half bracket, the lower half bracket, and the front and rear end plates are connected by bolts to form a...

Embodiment 2

[0048] A method for gamma-ray non-destructive detection of a hidden section of a cable, which uses the gamma-ray non-destructive detection cable concealed section detection device described in Embodiment 1 of the present invention to realize the method for non-destructive detection of a cable hidden section. The gamma-ray flaw detector probe and film of the detection device for the hidden section of the flaw detection cable are sent to the section to be inspected to form an effective inspection; The bridge deck protective cover, disassemble the inner vibration damping device and other parts of the cable, connect the upper and lower half brackets around the cable with bolts, install the gamma ray flaw detector probe 7 on the upper half bracket of the probe mounting support, and put the The photosensitive film support 16 with the photosensitive film installed is installed on the lower half support of the probe installation support; the probe detection crawling device is sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com