Antistatic waterborne polyurethane coating and preparation method thereof

A water-based coating and antistatic technology, applied in polyurea/polyurethane coatings, conductive coatings, coatings, etc., can solve the problems of high cost, environmental protection, and complicated methods of single carbon nanotube conductive fillers, and achieve antistatic performance reduction , small amount of addition, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

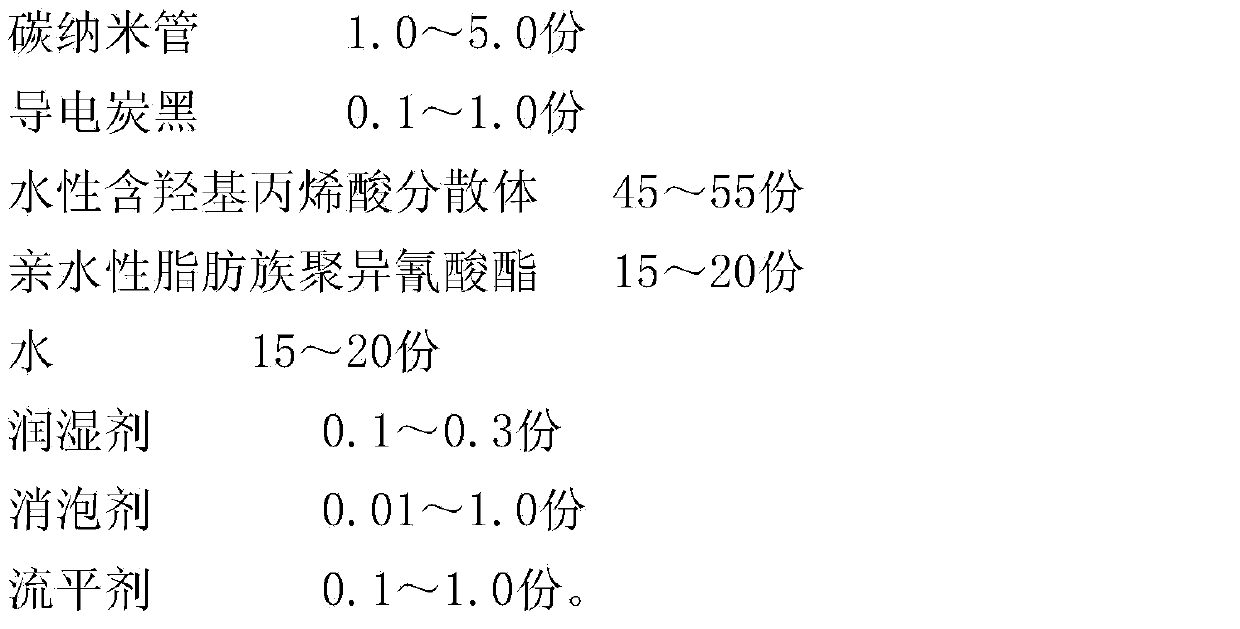

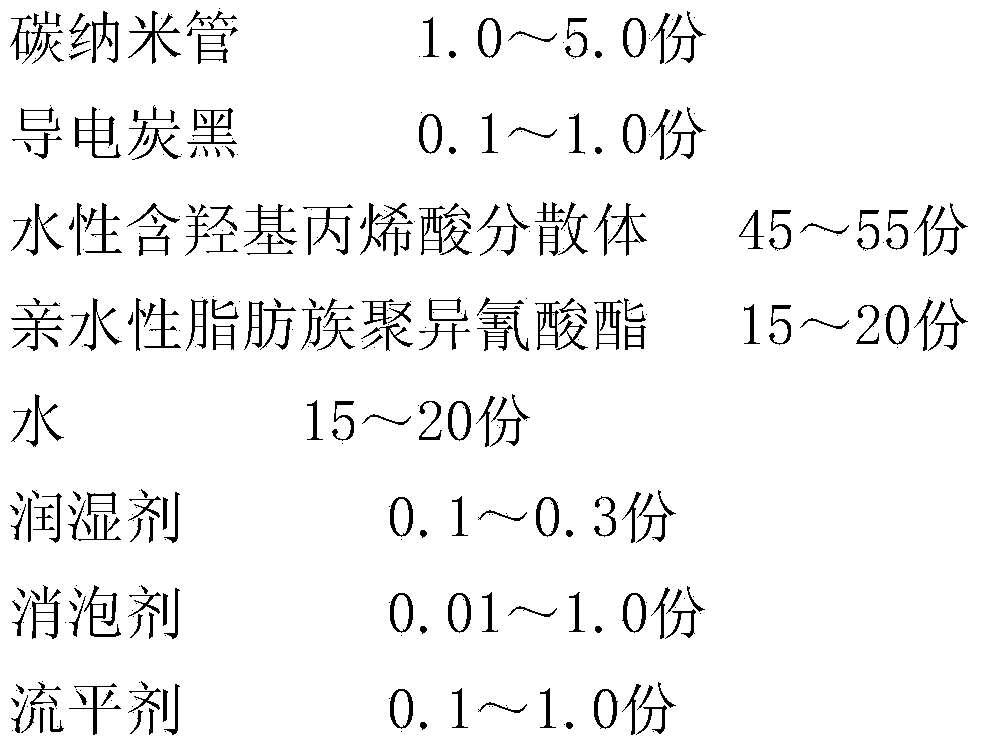

Method used

Image

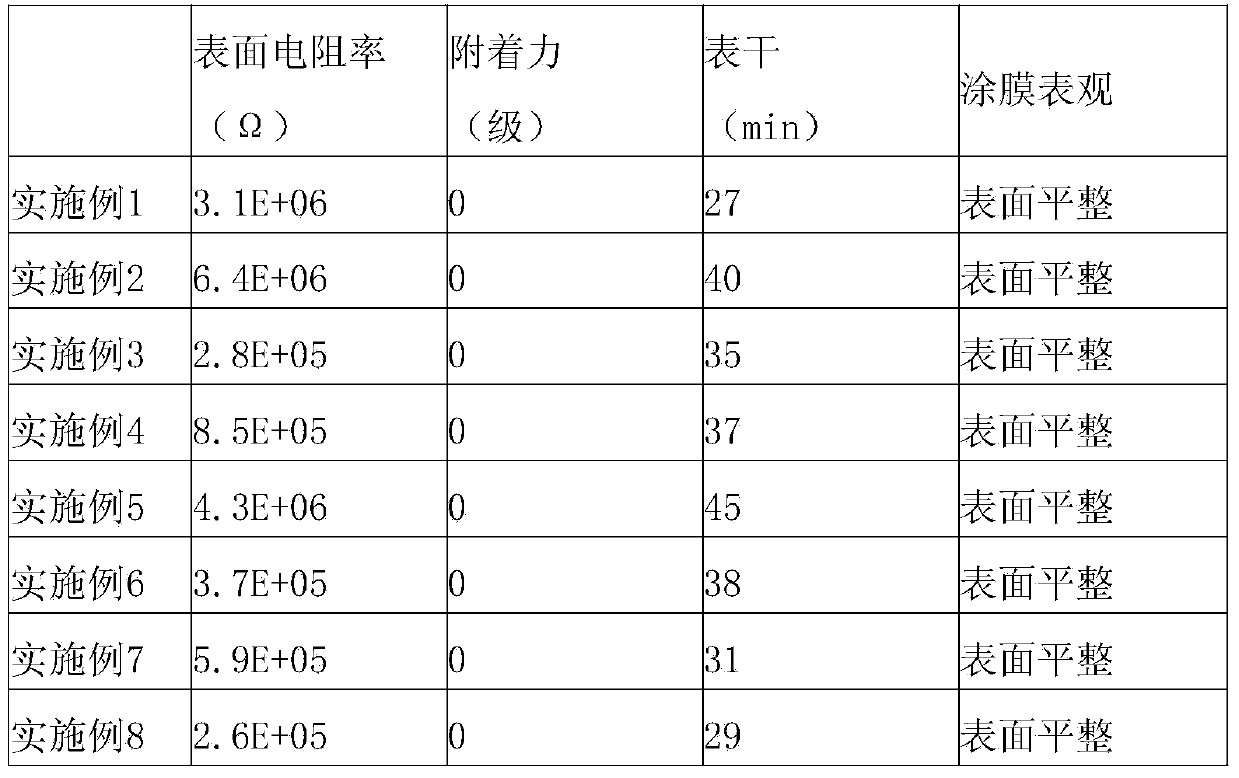

Examples

Embodiment 1

[0017] 1. Put 1.5 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio is 3:1), under the action of ultrasonic vibration and mechanical stirring, treated for 2.5h, and then washed with a large amount of deionized water until neutral.

[0018] 2. Add 45 parts of aqueous hydroxyl-containing acrylic acid dispersion (Bayhydrol XP series 2457) into the cone mill, add 1.0 parts of carbon nanotubes obtained in step 1, 0.2 parts of conductive carbon black, and 0.1 part of wetting agent under medium speed grinding , 0.03 parts of defoamer, 0.2 parts of leveling agent, 15 parts of water, dispersed for 20 minutes.

[0019] 3. Add 16 parts of hydrophilic aliphatic polyisocyanate (Bayhydur XP series 2451) and disperse for 10 minutes to obtain a waterborne polyurethane antistatic coating containing carbon nanotubes.

Embodiment 2

[0021] 1. Put 2.0 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio is 3:1), under the action of ultrasonic vibration and mechanical stirring, treated for 4h, and then washed with a large amount of deionized water until neutral.

[0022] 2. Add 50 parts of aqueous hydroxyl-containing acrylic dispersion (Bayhydrol XP series 2470) into the cone mill, add 2.0 parts of carbon nanotubes obtained in step 1, 0.3 parts of conductive carbon black, and 0.15 parts of wetting agent under medium speed grinding , 0.02 parts of defoamer, 0.1 parts of leveling agent, 17 parts of water, dispersed for 25 minutes.

[0023] 3. Add 17 parts of hydrophilic aliphatic polyisocyanate (Bayhydur XP series 2547) and disperse for 10 minutes to obtain a waterborne polyurethane antistatic coating containing carbon nanotubes.

Embodiment 3

[0025] 1. Put 4.0 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio: 3:1) was treated with ultrasonic vibration and mechanical stirring for 5 hours, and then washed with a large amount of deionized water until neutral.

[0026] 2. Add 48 parts of aqueous hydroxyl-containing acrylic acid dispersion (Bayhydrol XP series 2546) into the cone mill, add 4.0 parts of carbon nanotubes obtained in step 1, 0.5 parts of conductive carbon black, and 0.3 parts of wetting agent under medium speed grinding , 0.05 parts of defoamer, 0.5 parts of leveling agent, 20 parts of water, dispersed for 30 minutes.

[0027] 3. Add 20 parts of hydrophilic aliphatic polyisocyanate (Bayhydur XP series 2451) and disperse for 20 minutes to obtain a waterborne polyurethane antistatic coating containing carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com